A kind of oblique paddle type paddle agitator blade

A stirrer and blade technology, applied in the field of oblique paddle paddle stirrer blades, can solve the problems of difficult pulping, and achieve the effects of fast paddle speed, reduced blade load, and high paddle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

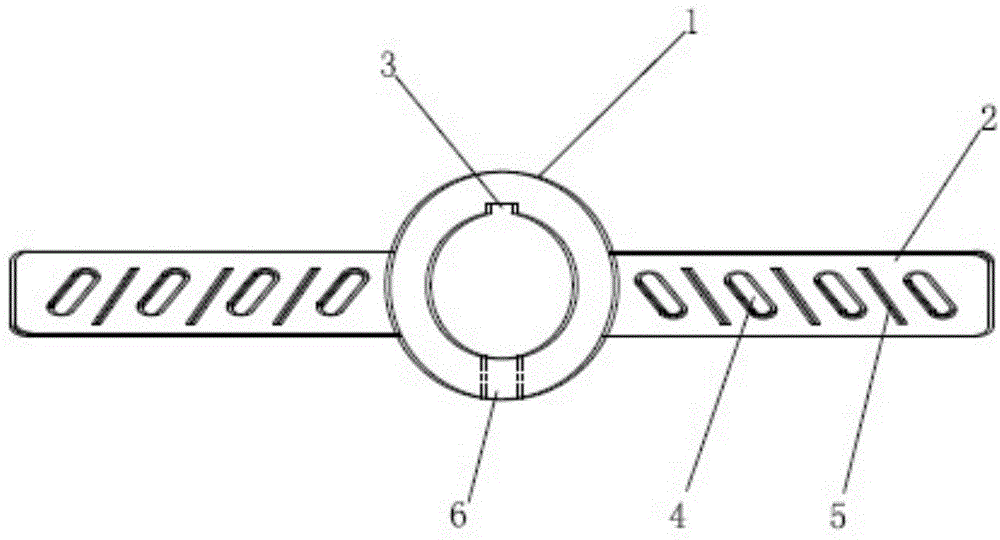

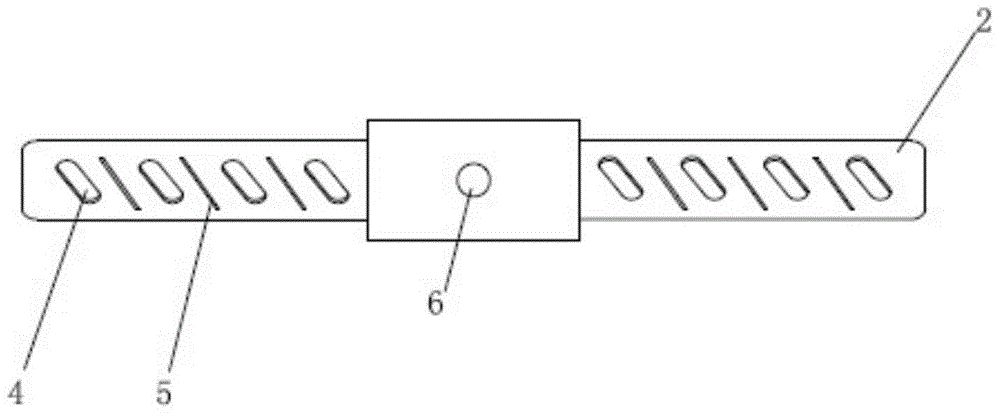

[0018] Combine below Figure 1 to Figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0019] A kind of oblique paddle type paddle agitator blade, comprising a stirring shaft 1 and several blades 2 arranged on the stirring shaft 1, a plurality of through holes 4 are evenly distributed on the blades 2, adjacent to the through holes A stirring knife 5 is arranged between the 4. The mixing knife breaks and separates the filter cake with the rotation of the blade. The through hole on the blade can not only effectively reduce the load on the blade, but also allow the tiny filter cake in the slurry to pass through the through hole, further making the filter cake Breaking and separating, the present invention can stir and paddle the filter cake with high solid content, and the paddle speed is fast and the paddle efficiency is high.

[0020] The stirring knives 5 are respectively arranged on the front and back sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com