Automatic numerical control fin formation preparing method

An automatic, finned technology, applied in the direction of heat exchange equipment, etc., can solve the problem of not seeing the production and manufacturing process of heat transfer fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

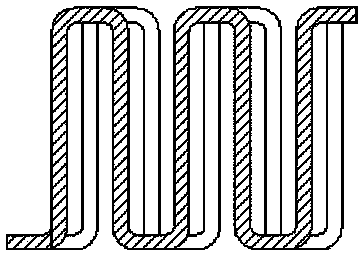

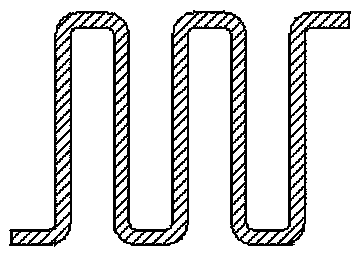

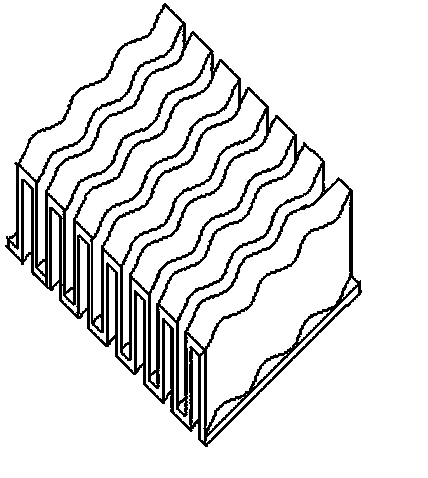

[0031] For the automatic numerical control fin forming production line described in the present invention, the process control flow for producing heat transfer fins is shown in Figure 4 shown.

[0032] 1) The rolled aluminum foil is clamped on the uncoiler, and the uncoiler and stop of the uncoiler are controlled by the first photoelectric sensor;

[0033] 2) The aluminum foil is sent to the CNC punching machine for punching at a certain rate ratio, during which the matching speed of punching is controlled by the forming machine, and the punching speed of the punching equipment is controlled by the second photoelectric sensor to increase or decrease;

[0034] 3) The punched aluminum foil is sent to the forming machine to be punched into shape;

[0035] 4) The formed fins are transported to the finishing and cutting equipment. The front stage of the finishing system is equipped with a semi-flexible belt conveyor unit to transport the formed fins. The operation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com