Chemical cargo ship special coating construction process

A construction technique and chemical tanker technology, applied to coatings, special surfaces, and devices for coating liquids on surfaces, etc., can solve problems such as the lack of standardized process procedures, improve labor productivity, improve product quality, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

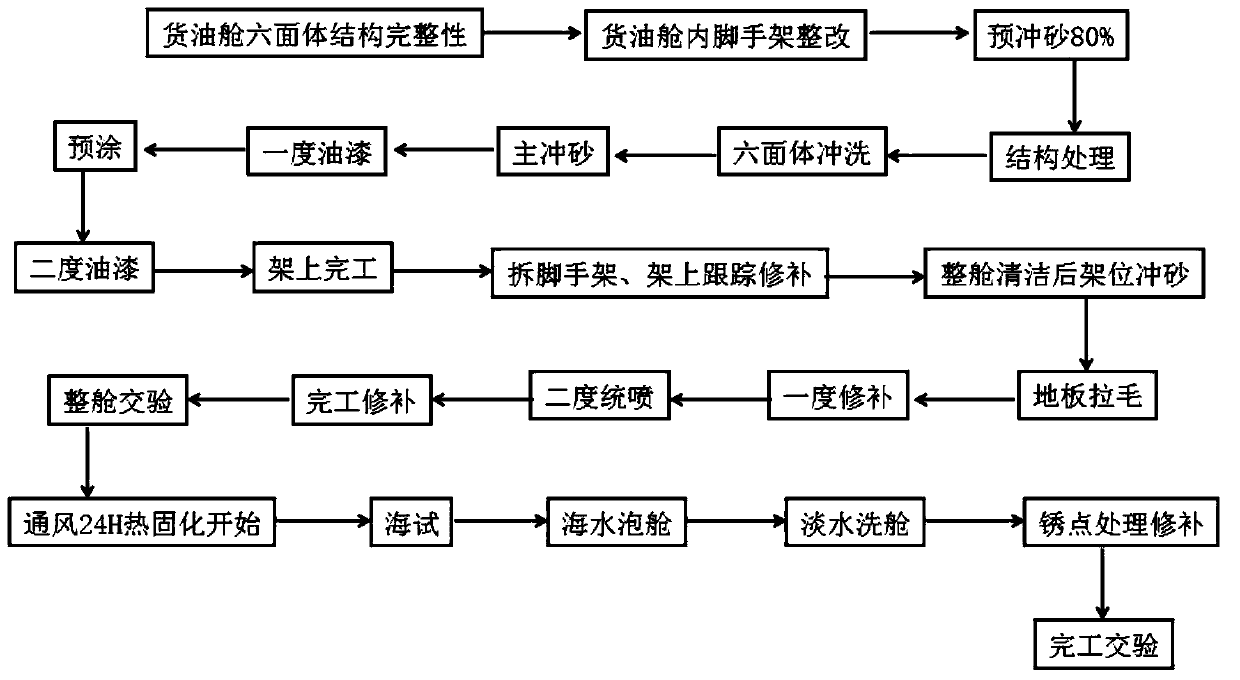

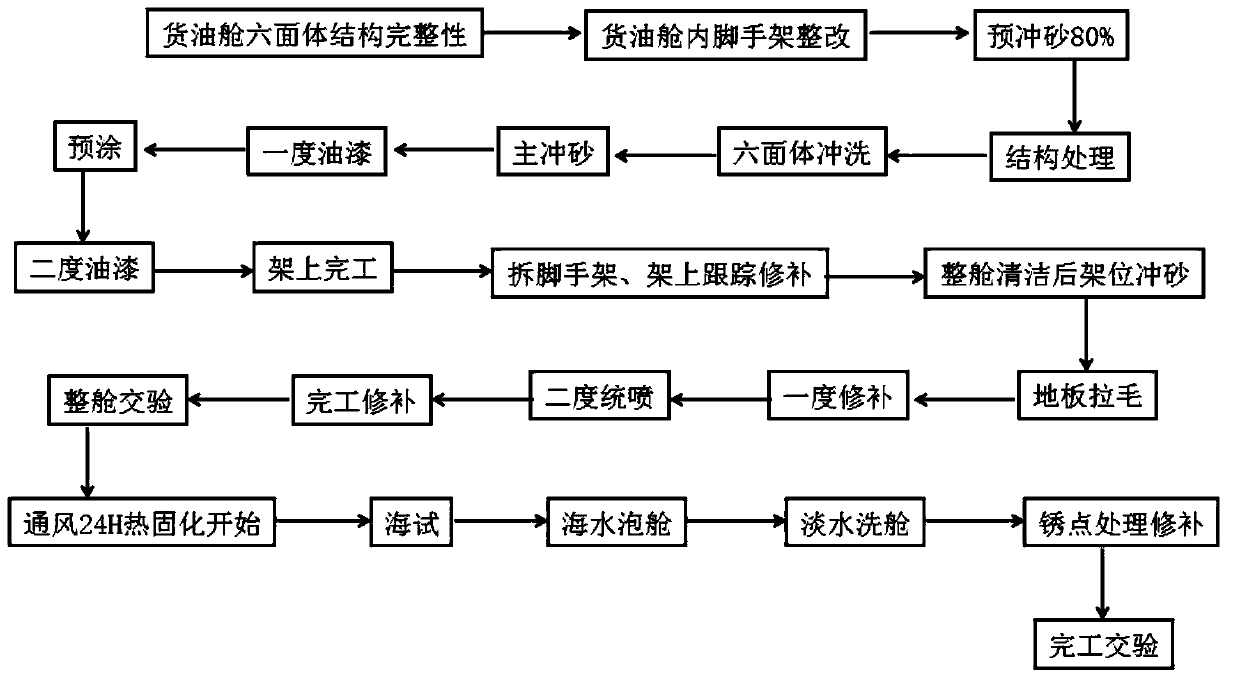

[0024] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0025] Such as figure 1 As shown, a special coating construction process for chemical tankers includes the following steps:

[0026] Step 1. Set up scaffolding for construction;

[0027] Step 2, pre-washing and cleaning the cabin after removing impurities and polishing;

[0028] Step 3: Rinse the cabin and carry out the main sand washing treatment after drying;

[0029] Step 4. Spraying paint on the cabin and repairing defects;

[0030] Step 5, thermally curing the cabin.

[0031] Wherein, preferably, the distance between the scaffold and the bulkhead in step 1 is preferably 25-30 cm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com