Hobbing die with automatic locking

An automatic locking and gear hobbing die technology, applied in the field of gear hobbing die, can solve the problems of affecting product quality, high labor intensity of manually rotating screw shanks, and the inability of workpiece and worktable to rotate synchronously, so as to achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

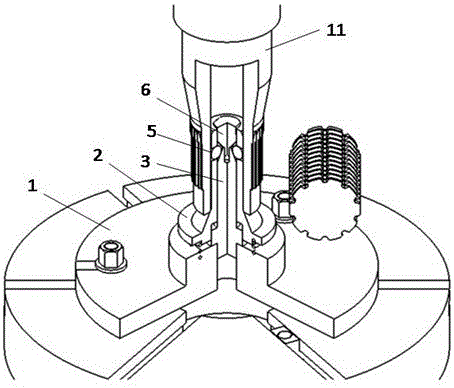

[0013] The present invention will be further described below in conjunction with accompanying drawing:

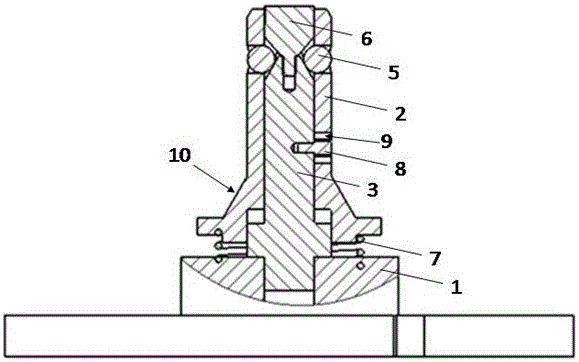

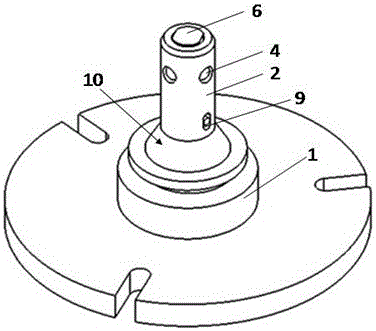

[0014] Such as figure 1 , figure 2 , image 3 A hobbing mold that can be automatically locked as shown includes a mold base 1 and a mold body 2 arranged above the mold base 1. A mandrel 3 is vertically provided on the mold base 1, and a hole 4 is provided on the mold body 2. A steel ball 5 is provided in the hole 4, a plug 6 is provided at the upper end of the mandrel 3, and the mold body 2 is sleeved on the mandrel 3 and the top 6. The characteristic is that the mandrel 3 is fixedly connected with the mold base 1, and the mandrel The upper end of 3 is provided with a conical surface matched with the steel ball 5, and a return spring 7 is provided between the mold body 2 and the mold base 1, and the mold body 2 can only move up and down along the axial direction of the mandrel 3.

[0015] Furthermore, one end of the return spring 7 is fixed to the lower end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com