Positioning structure for sprue bush

A technology of positioning structure and sprue sleeve, applied in the field of product mold structure, can solve the problems of mixed air impurity flow rate, unevenness, loose flow channel, etc., to achieve the effect of uniform flow rate and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

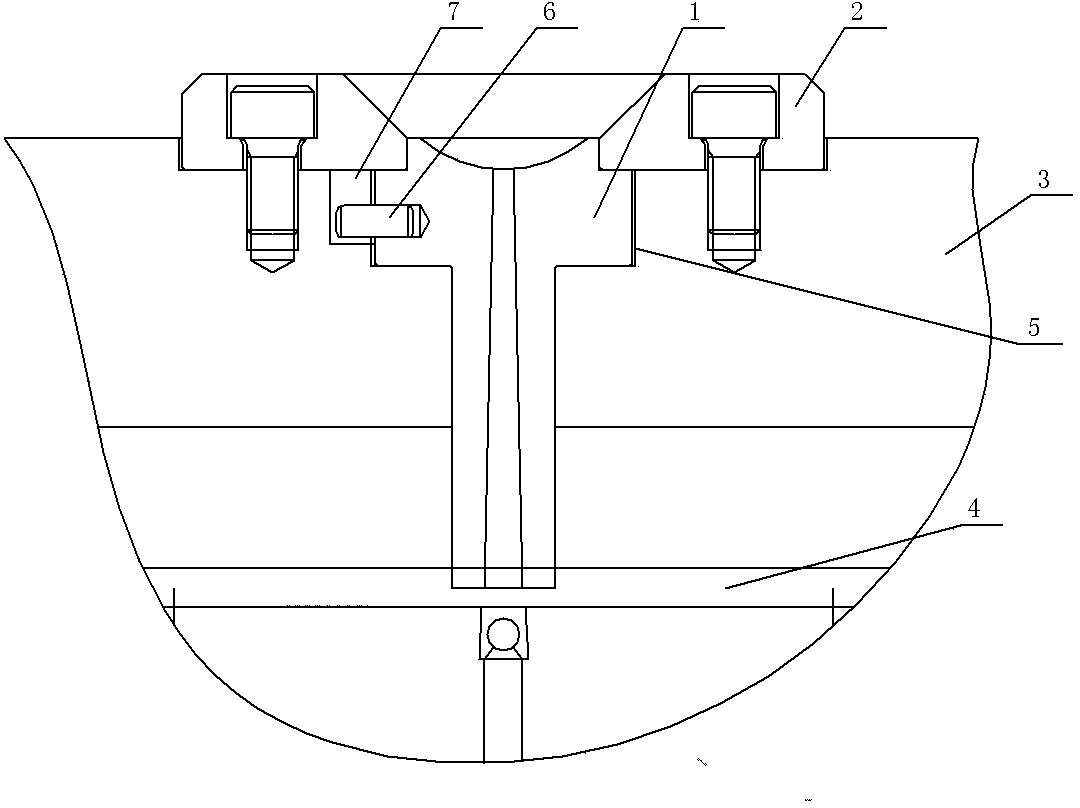

[0007] See figure 1 , which includes a sprue sleeve 1, an upper gland 2, a panel 3, and a flow channel 4. The sprue sleeve 1 is placed in the installation cavity 5 of the panel 3, the lower end of the sprue sleeve 1 communicates with the flow channel 4, and the upper gland 2 covers Installed on the upper end surface of the sprue sleeve 1, the upper gland 2 is fastened to the panel 3, the side of the sprue sleeve 1 is fastened with protruding positioning screws 6, and the upper end surface of the installation cavity 5 of the panel 3 is provided with a positioning slot 7, the protruding part of the positioning screw 6 is placed in the positioning slot 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com