Rubber composite for car radial tire treads

A rubber composition and composition technology, applied in the field of rubber compositions for radial tire treads, can solve problems such as increased hysteresis effect, impact on tire wear resistance, compatibility differences, etc., and achieve excellent wet skid resistance Effect

Active Publication Date: 2013-12-11

QINGDAO HAIJIA AJUVANTS

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the relationship between the structure of the resin and its molecular weight, generally speaking, after adding the resin, the energy loss of the rubber compound will increase, that is, the hysteresis effect will increase

If resin is added to the tread, it will increase the rolling resistance of the tire

At the same time, due to the difference in compatibility between the chemical structure of the resin itself and the rubber and its reinforcing system, it will affect the wear resistance of the tire.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

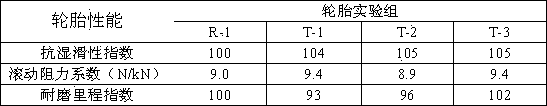

[0040] The present invention sets up 3 groups of examples: T-1, T-2, T-3, and 1 group of reference example R-1.

[0041] The radial tire tread consists of a rubber composition of the following components:

[0042]

[0043] Wherein, preferred embodiment is:

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a rubber composite applied to car radial tire treads. The rubber composite comprises the following substances of (i) dialkene elastomer; (ii) more than 30 phr of inorganic reinforcing filler; (iii) 2-15 phr of a coupling agent; (iv) 0-20phr of a plasticizer; and (v) 2-20 phr of resin, wherein phr represents the weight parts of all materials accounting for 100 parts by weight of dialkene elastomer. When the tire tread comprising the rubber composite is in use, the tire tread has excellent slip resistance and rolling resistance, and the tires are endowed with the balance of wetland grip, rolling resistance and wear resistance.

Description

technical field [0001] The present invention relates to rubber compositions, in particular rubber compositions for radial tire treads. Background technique [0002] The wet skid resistance, rolling resistance and wear resistance of tires are the most concerned performances of users. Wet skid resistance refers to the grip on wet ground, and the braking distance in rainy days is directly related to the driving safety of the vehicle. Rolling resistance, namely fuel economy, is an important indicator of greenhouse gas carbon dioxide emissions, environmental protection and energy saving. Abrasion resistance is the mileage of the tire, which is directly related to the service life of the tire. However, these three performances are mutually restrained and ebb and flow, which is called the magic triangle of tire performance. For example, if the grip in the wet is improved, the wear resistance will be reduced; the rolling resistance will also be reduced in the wet. In the 1990s, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L9/06C08L9/00C08L7/00C08K13/02C08K3/36C08K3/04

CPCY02T10/86

Inventor 贺炅皓宫相勤付丽徐伟王贞英于蕾何坚坚

Owner QINGDAO HAIJIA AJUVANTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com