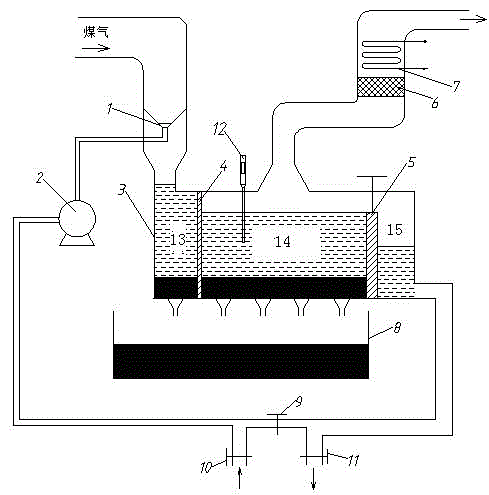

Combined dust removal and desulfurization system for coal gas

A desulfurization system and gas technology, applied in gas dust removal, combustible gas purification, combustible gas purification/reconstruction, etc., can solve the problems of subsequent gas-steam power generation equipment blockage, complex equipment, high energy consumption, etc., and achieve high dust removal and desulfurization efficiency. , low cost, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Experimental synthesis of raw gas 1 component is as follows: wherein hydrogen sulfide gas 800ppm, containing a small amount of other gas components such as COS, dust amount 1.5mg / Nm 3 , The pH of the eluent is 10, the content of hydrogen sulfide gas after elution and drying is about 14ppm, the content of COS and other gases has also reached a safe level, and the amount of dust is basically zero.

Embodiment 2

[0050] Embodiment 2: experimental synthesis crude gas 2 components are as follows: wherein hydrogen sulfide gas 1000ppm, contain other gas components such as a small amount of COS, dust amount 1.8mg / Nm , eluent pH is 12, hydrogen sulfide gas after washing and drying The content of COS is about 8.5ppm, the content of COS and other gases has also reached a safe level, and the amount of dust is basically zero.

[0051] According to the experimental results, the desulfurization efficiency of the system reaches over 99%, and the dust removal rate basically reaches 100%. The reaction equation is as follows:

[0052] (1)

[0053] (2)

[0054] In the formula, M represents sodium (Na) or potassium (K).

[0055] Feasibility and prospect of popularization and application of the present invention: The present invention relates to a combined dust removal and desulfurization system of an IGCC power generation system. At present, the IGCC power generation syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com