Installation method for steel skeleton of large steel structure factory building

An installation method and steel structure technology, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., can solve the problems of inability to carry out overall transportation and overall hoisting of steel columns, large driving tonnage, and large steel columns of workshops, etc. , to achieve the effect of reducing the installation cost, reducing the cost, and reducing the lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

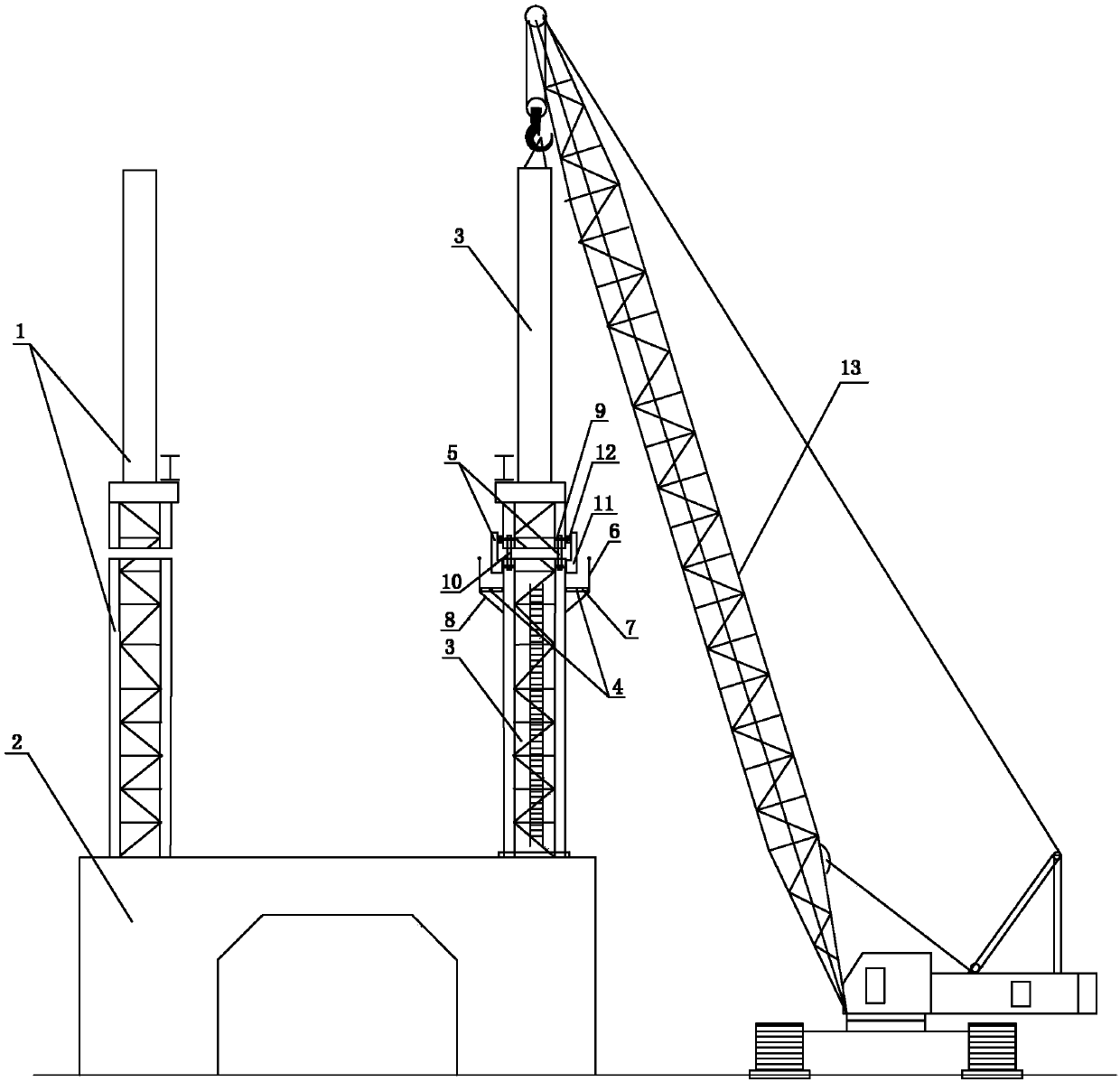

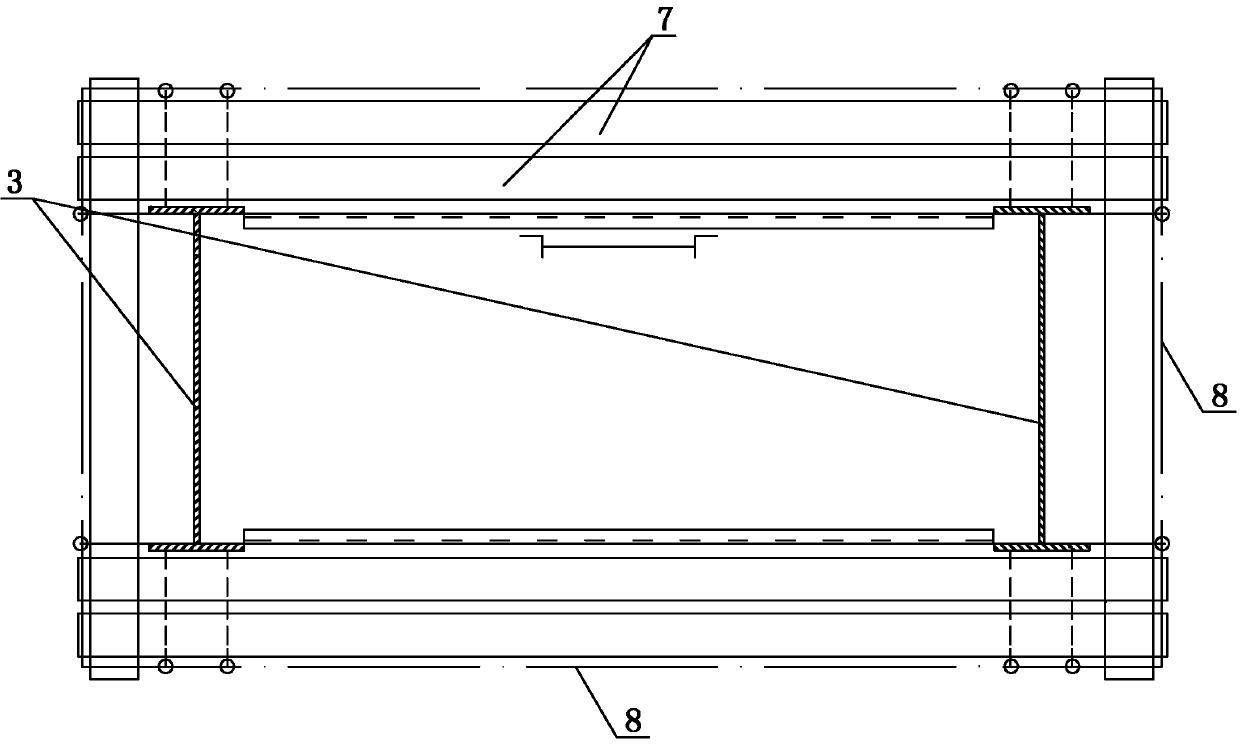

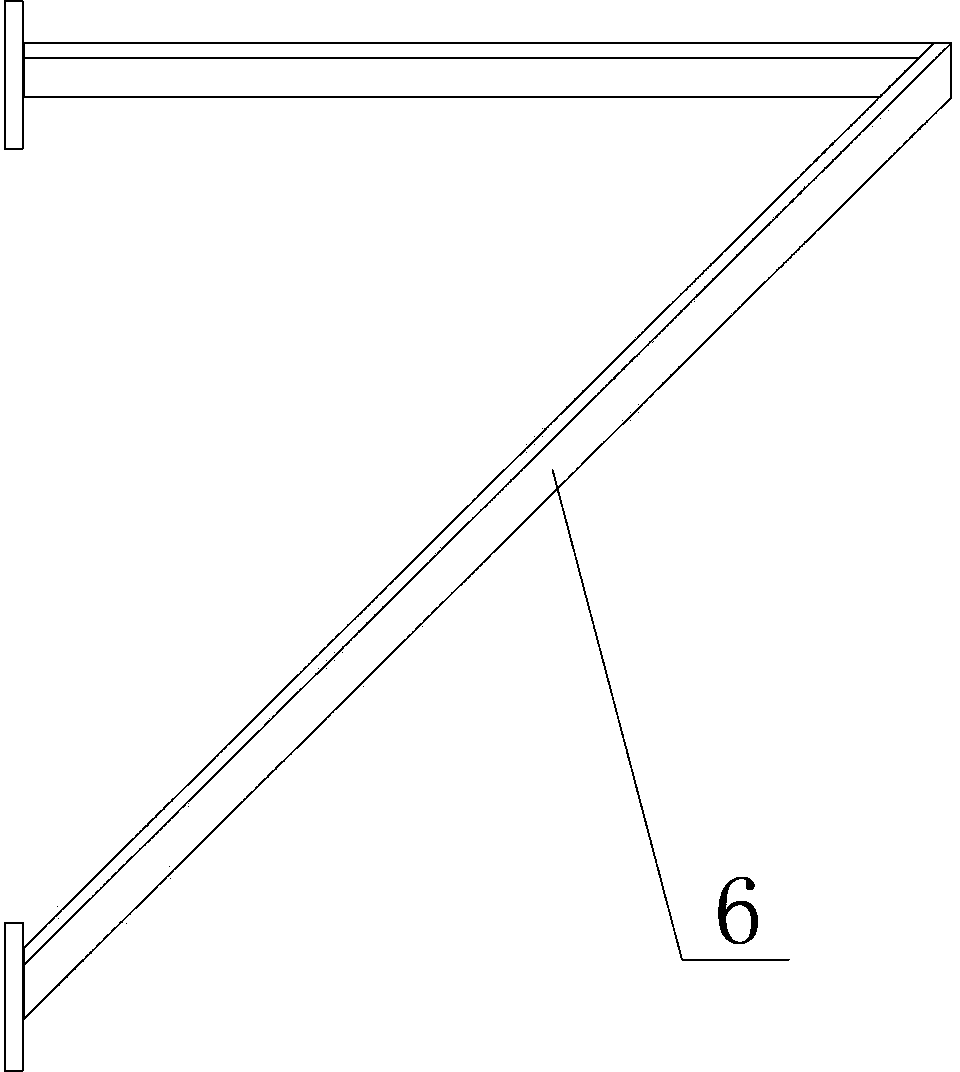

[0021] Such as figure 1 , figure 2 as well as image 3 Shown is a low installation cost provided by the present invention, which is convenient, quick and safe to install and operate, and is used for the installation method of the steel frame of a large-scale steel structure workshop. The installation method includes the following steps,

[0022] a. Set out the wires and measure the basic size of the steel column, and use the theodolite, level meter and length measuring ruler to put the vertical and horizontal installation centerlines of the steel columns 1 that need to be installed to form the steel skeleton of the steel structure factory building on the installation foundation 2, And use the length measuring ruler to measure the geometric dimensions of each segment of the segmented steel columns 3 that make up the steel column 1, and then determine the vertical hoisting of each segmented steel column 3 according to the measured geometric dimensions of each segmented steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com