Multi-cam self-adaptive multi-gear automatic transmission

An automatic transmission and self-adaptive technology, applied in the direction of transmissions, transmission parts, belts/chains/gears, etc., can solve problems such as reducing the sense of setback, achieve volume reduction, scientific and rational transmission chain, good energy saving and consumption reduction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

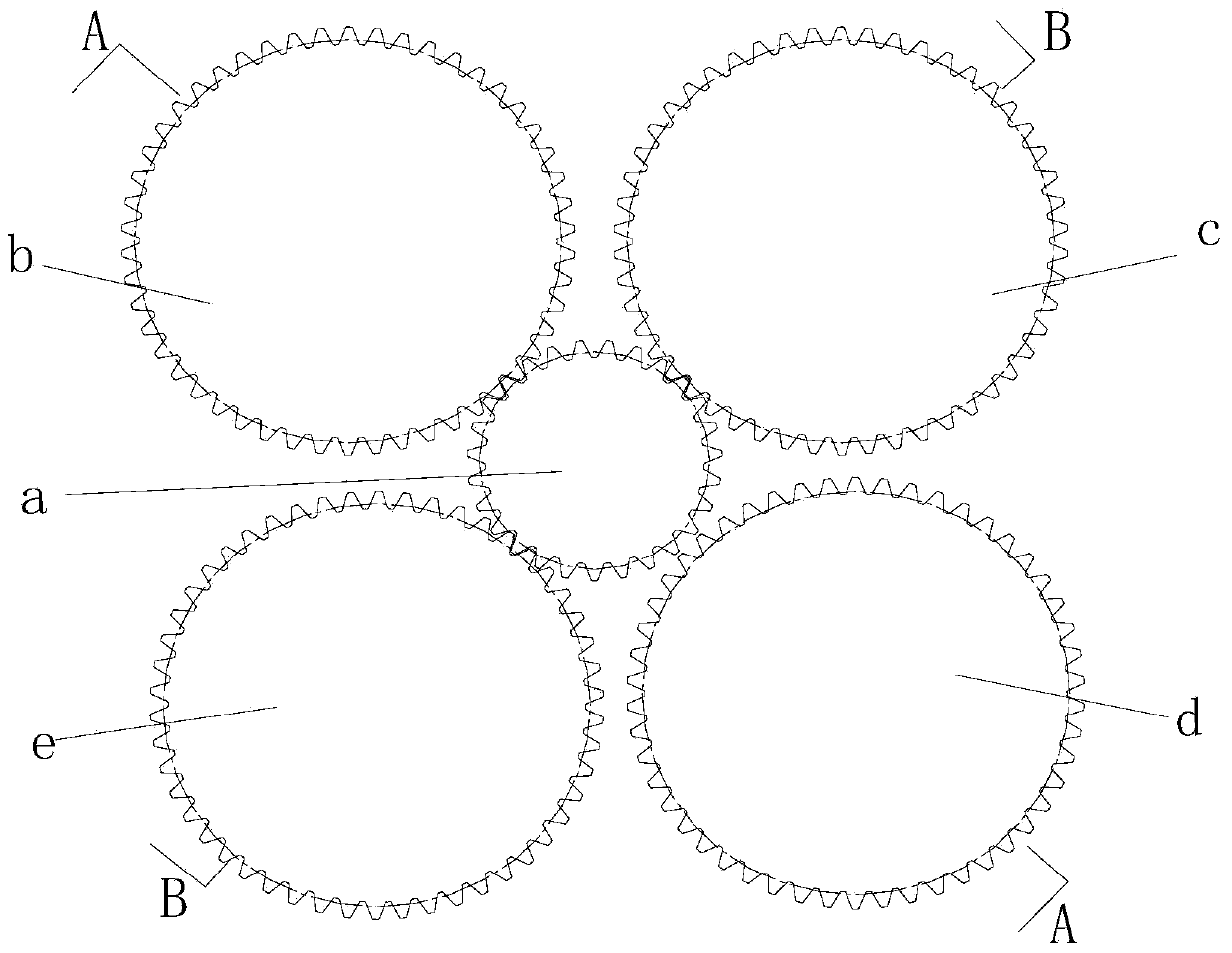

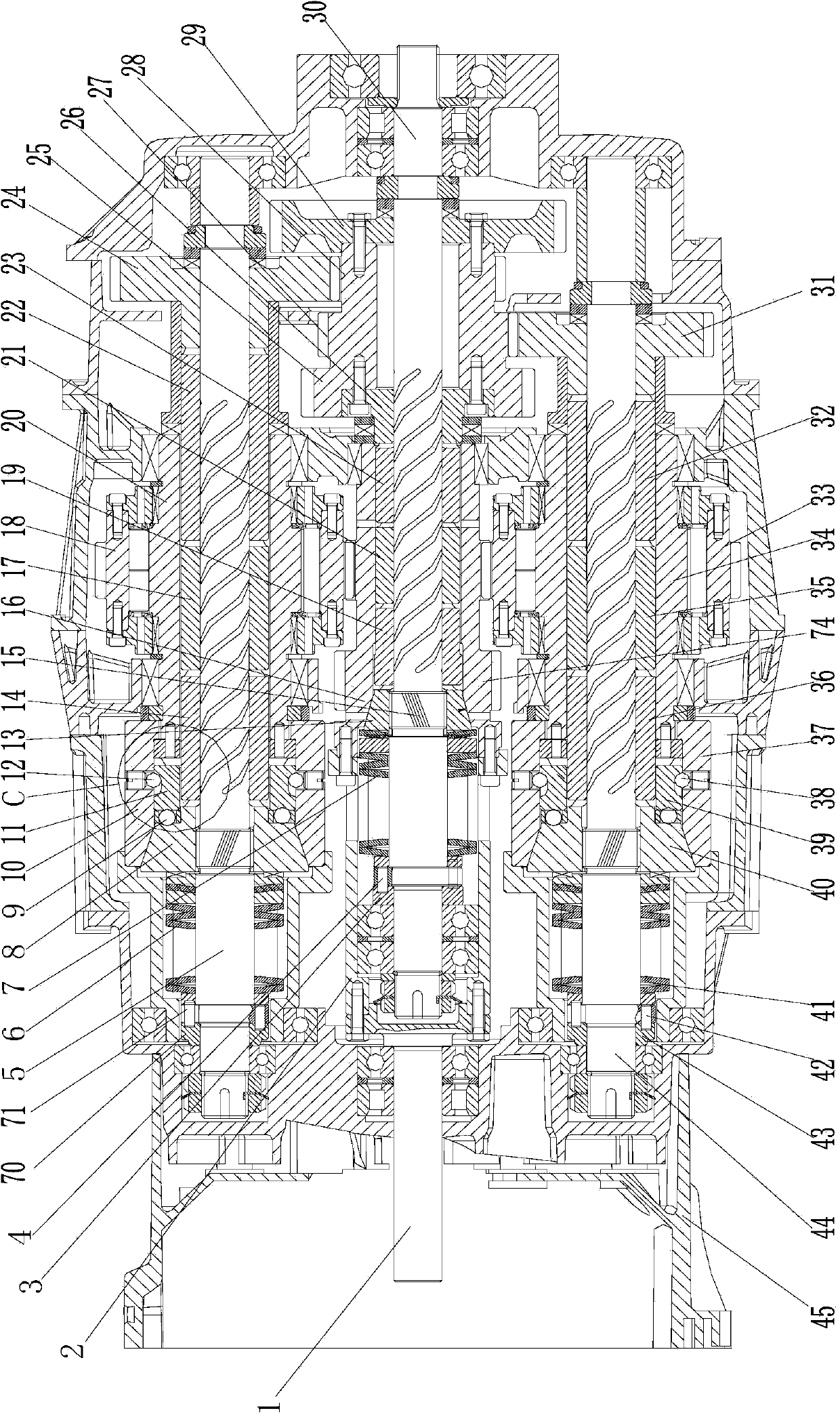

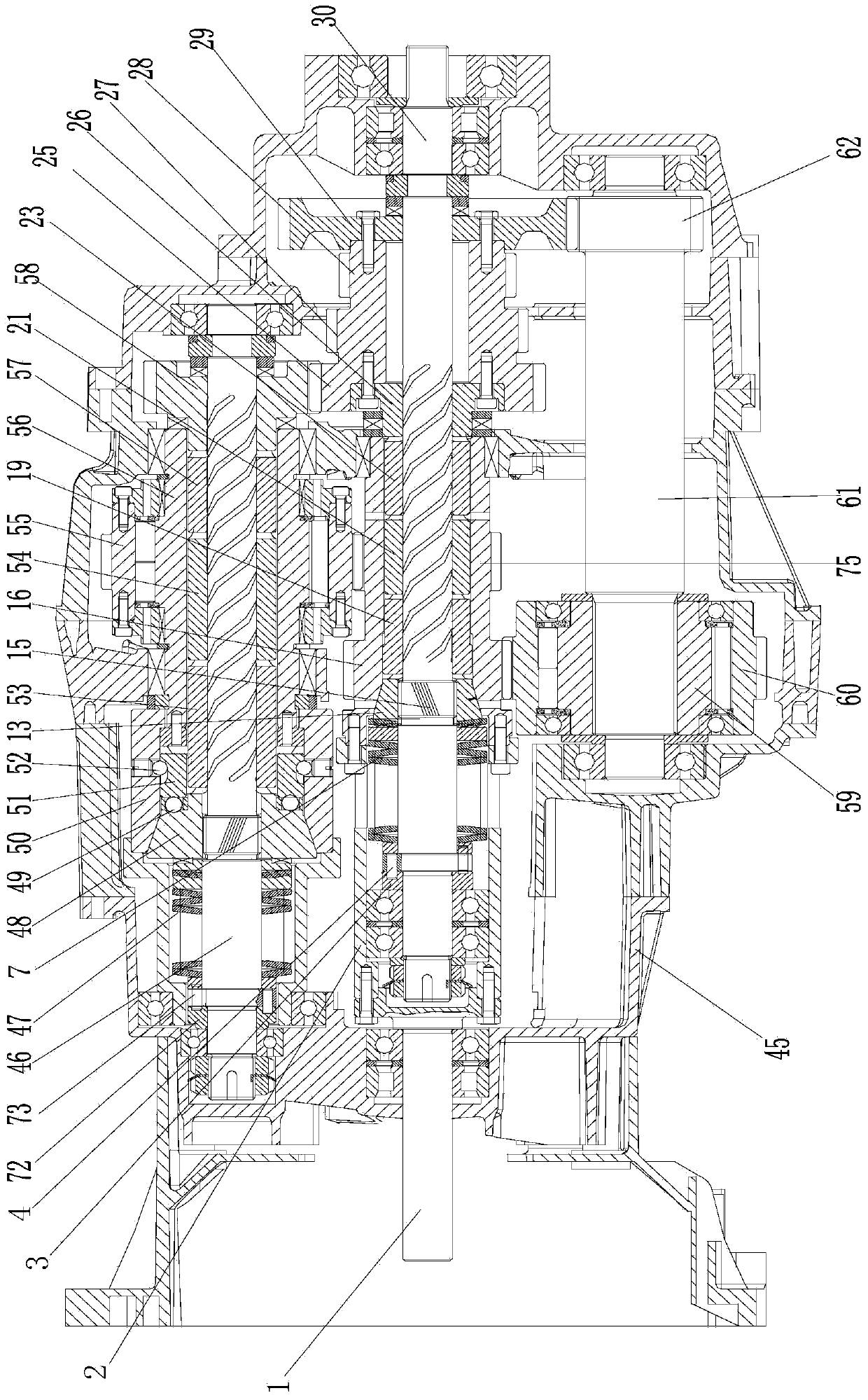

[0039] figure 1 It is a schematic diagram of the layout of the present invention, figure 2 for figure 1 Schematic diagram of the cross-sectional structure along A-A direction, image 3 for figure 1 Schematic diagram of the cross-sectional structure along B-B direction, Figure 4 It is a schematic diagram of the structure of the axial outer tapered sleeve of the annular body a and n gears, Figure 5 It is a schematic diagram of the structure of the cam sleeve a and the n gear cam sleeve, Image 6 It is a schematic diagram of the end face cam development of the cam sleeve a and the n gear cam sleeve, Figure 7 for figure 2 Enlarged view at C, Figure 8 Schematic diagram of the structure of the overrunning clutch, Figure 9 for Figure 8 Enlarged view at E, Figure 10 for Figure 8 Sectional view along D-D, as shown in the figure: the multi-cam adaptive multi-speed automatic transmission of the present invention includes a casing 45, a power input shaft 1 and a power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com