A device for collecting condensate on the inner wall of wet flue gas flue

A collection device and technology in the flue, which is applied in the exhaust gas device, combustion product treatment, combustion method, etc., can solve the situation that the inner wall of the flue is easy to condense, and does not have the function of collecting condensate on the inner wall of the wet flue. and other problems to achieve the effect of avoiding re-accumulation, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

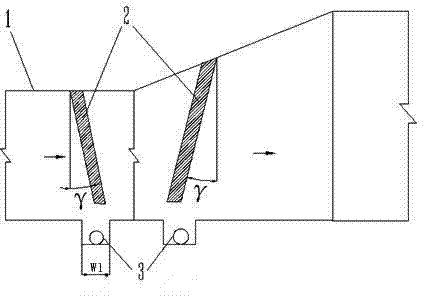

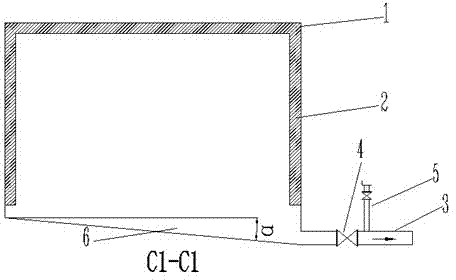

[0048] refer to Figure 1-5 A device for collecting condensate on the inner wall of a wet flue gas flue provided by the present invention is used in a flue with a rectangular cross-section, and includes at least one set of collection structures. Several collection structures are arranged on the inner wall of the flue The condensate on the wall is discharged from the flue, wherein the collection structure includes a collection tank 2 , a drainage tank 6 , a guide pipe 3 , a drain valve 4 and a flush valve 5 .

[0049] Specifically, such as image 3 As shown, the collection tank 2 is fixedly arranged on the top and both sides of the inner wall of the rectangular flue 1 by means of riveting, welding or bonding, and the direction of the notch of the collection tank 2 is opposite to the flow direction of the flue gas in the flue, so that The condensate on the inner wall of the flue 1 passes through the collection tank 2 when moving forward along the inner wall of the flue 1 under ...

Embodiment 2

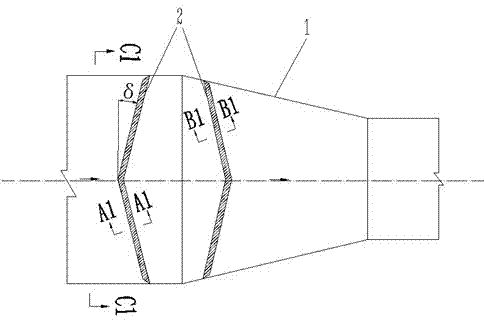

[0056] refer to Figure 6-9 In this embodiment, the device for collecting condensate on the inner wall of the wet flue gas flue is used in the circular flue, including at least one set of collection structures, and several collection structures are arranged on the inner wall of the circular flue The condensate is discharged from the flue. Wherein, the collection structure includes a collection tank 2 , a drainage tank 6 , a guide pipe 3 , a drain valve 4 and a flushing valve 5 .

[0057] Such as Figure 6-7 As shown, the collection tank 2 is fixedly arranged along the top of the circular flue 1 and the inner walls of the left and right sides, the collection tank 2 and the radial direction of the flue 1 are inclined at an angle γ, and the inclination direction of the collection tank 2 is in line with the inside of the flue 1. The flow direction of the flue gas is the same, and the range of the included angle γ is 10°≤γ≤20°, preferably 15°; in this embodiment, as Figure 8 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com