Method and system for measuring flow characteristic of biomass circulating fluidized bed boiler

A circulating fluidized bed, flow characteristics technology, applied in the direction of measuring devices, fluid dynamics tests, machine/structural component testing, etc., can solve the problem of difficult to clearly describe the flow characteristics, long period, gas-solid two-phase flow fluid Complexity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and drawings, but the implementation of the present invention is not limited thereto.

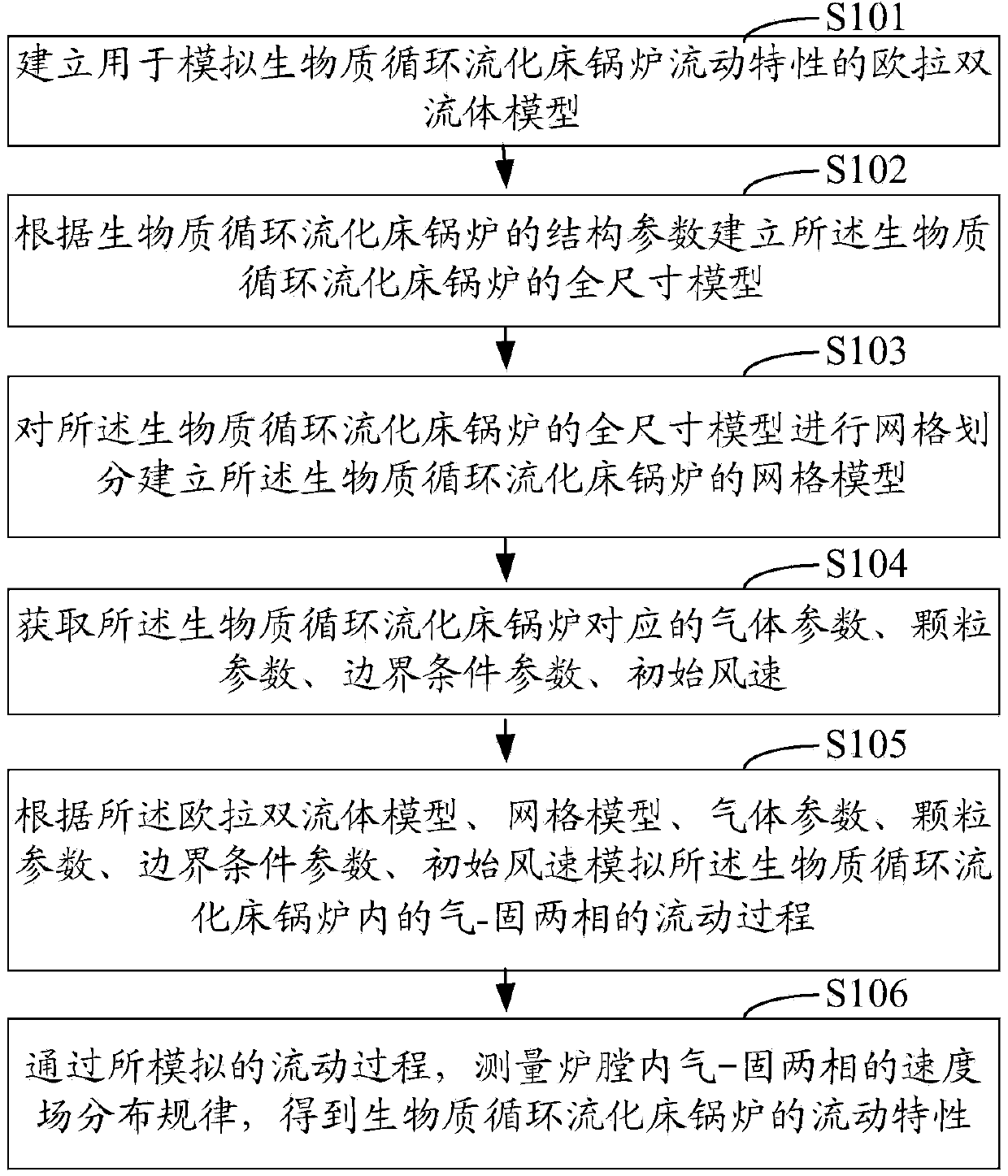

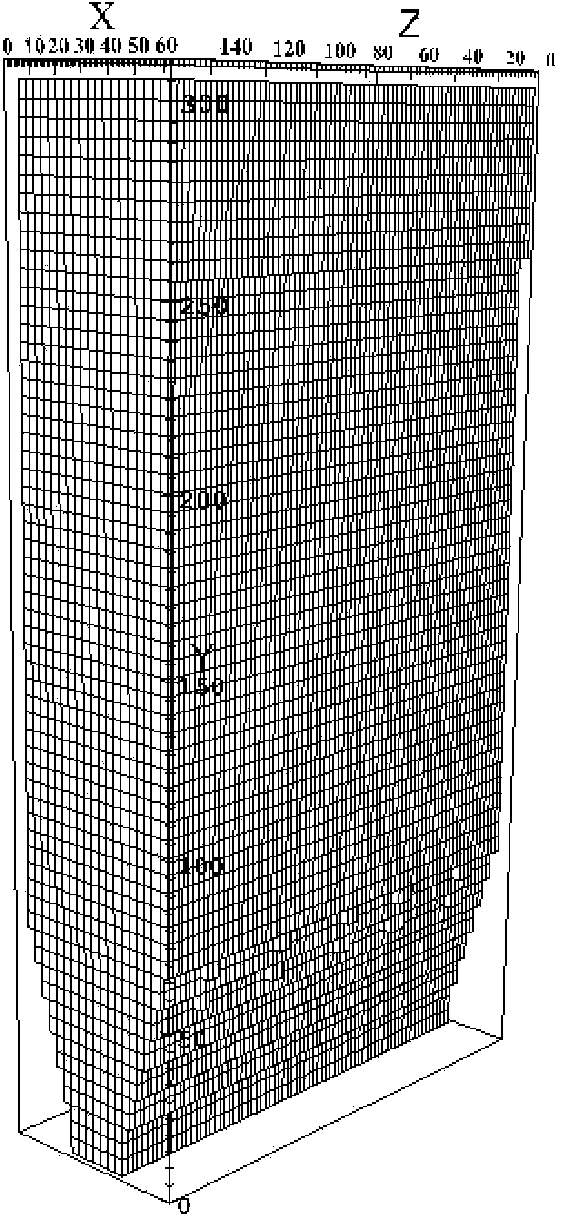

[0033] see figure 1 Shown is a schematic flow chart of an embodiment of the method for measuring the flow characteristics of a biomass circulating fluidized bed boiler according to the present invention. Such as figure 1 As described, the method for measuring the flow characteristics of a biomass circulating fluidized bed boiler in this embodiment includes the following steps:

[0034] Step S101: Establishing an Eulerian two-fluid model for simulating the flow characteristics of a biomass circulating fluidized bed boiler;

[0035] In the embodiment of the present invention, the calculation model used to simulate the flow characteristics of the biomass circulating fluidized bed boiler is the Euler two-fluid model; the Euler two-fluid model treats the particle phase as a fluid-like continuous ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com