Automatic weighted titration type micro-metering method and device

A micro-metering and titration technology, applied in the field of micro-metering, can solve the problems of reducing the accuracy of the metering, reducing the metering speed, etc., and achieve the effects of improving the accuracy, simple manufacturing structure, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

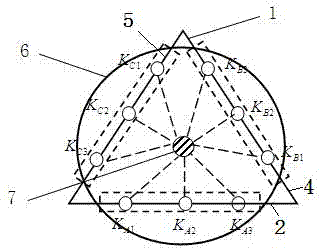

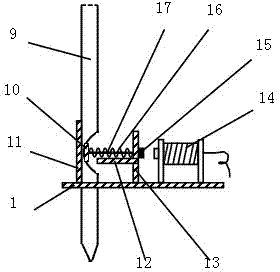

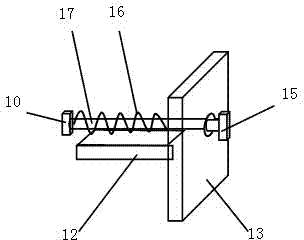

[0023] refer to Figure 1~2 , the top of the titration type automatic micro-metering device with weight in the present invention is a liquid storage tank 6, and the bottom is a support 1, and three types of burette assemblies are arranged between the liquid storage tank 6 and the support 1, which are respectively Class A burette assemblies 2. Type B burette assembly 4 and type C burette assembly 5. The three types of burette assemblies have the same installation structure, and are composed of three burettes with different weights representing different range specifications. The three burettes in each type of burette assembly are arranged in a straight line and the centerlines of the three burettes are in a plane. Inside. Each burette is supported on the bracket 1 . Among them, the class A burette assembly 2 is composed of weights Burette , the weight is Burette , the weight is Burette These three burettes with different range weight specifications are composed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com