Spray nozzle structure capable of regulating diameter of fogdrops rotationally along circumferential direction

A technology of rotating adjustment and spray head, applied in the direction of spraying device, spraying device, spraying device with movable outlet, etc., can solve the limitation of the ability and efficiency of absorbing the heat of high temperature flue gas, the lack of adjustable mechanism and strain capacity of the device, the flue gas Temperature changes and other problems, to achieve the effect of improving the atomization effect, the adjustment effect is obvious, and the speed of adjustment is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

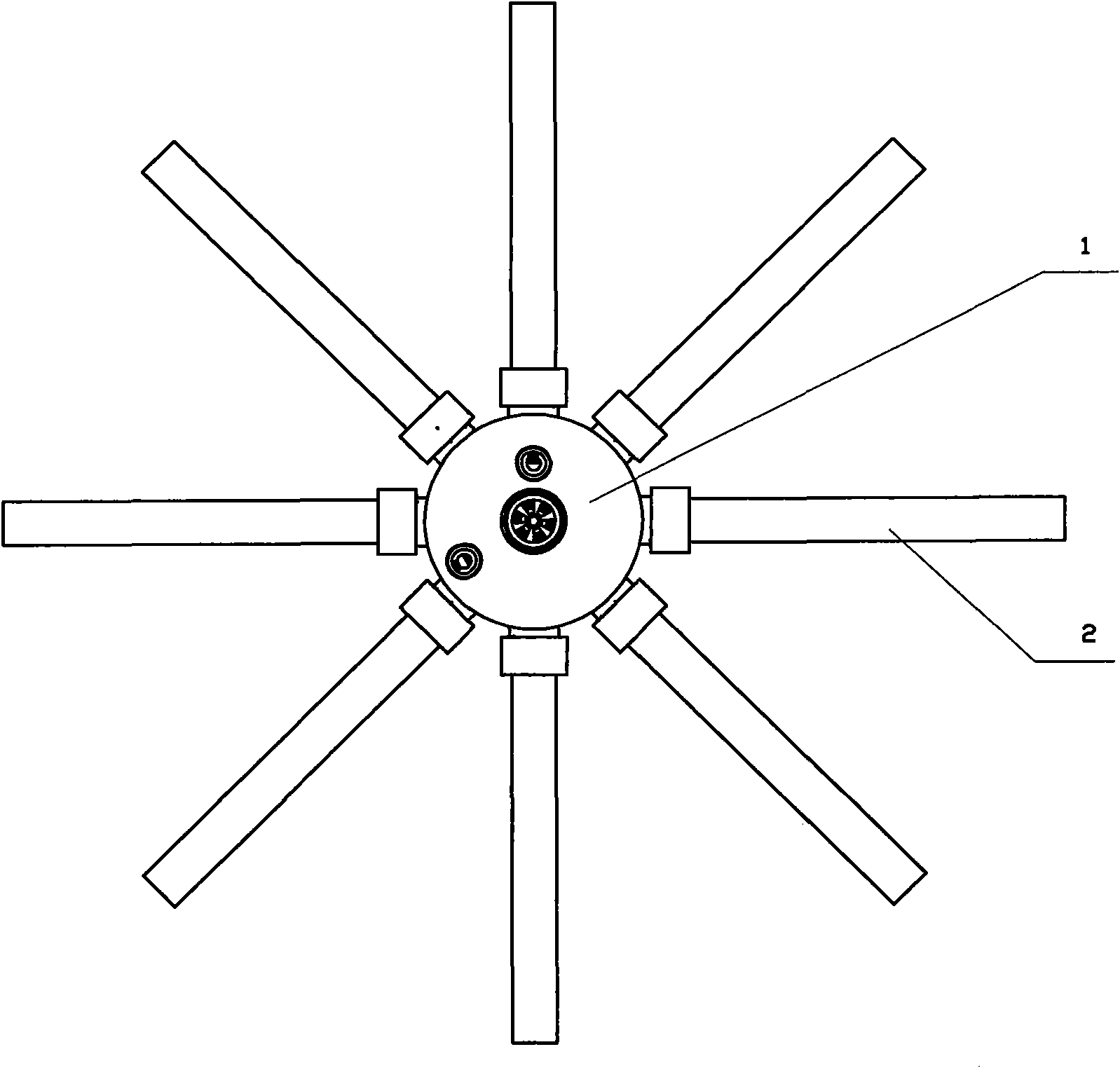

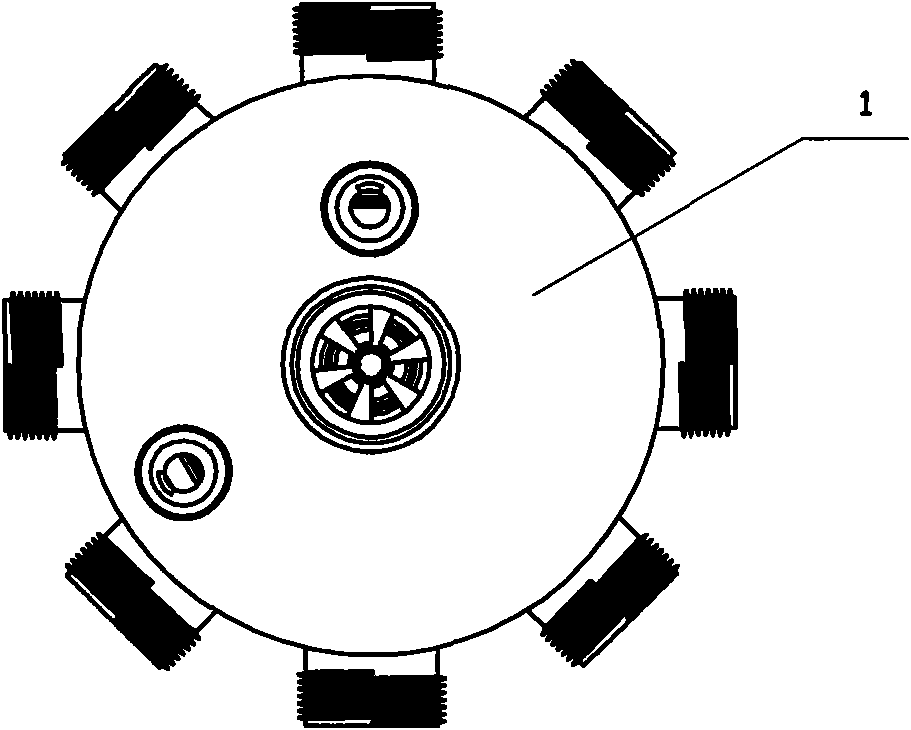

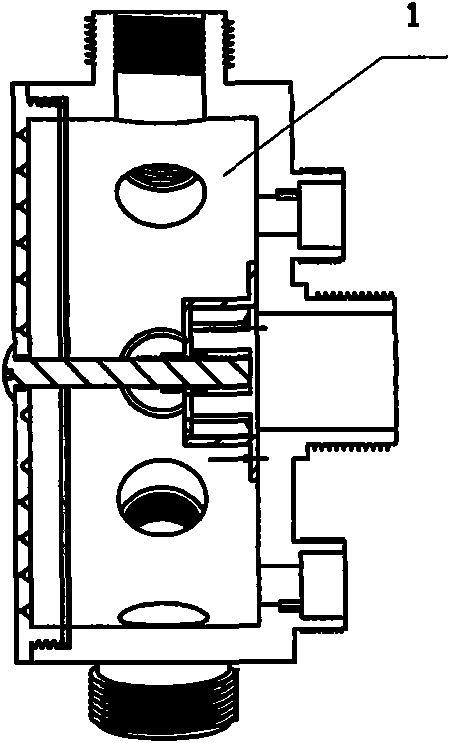

[0041]A cylindrical nozzle structure that rotates in the circumferential direction to adjust the diameter of the droplets. On the cylindrical wall of the cylindrical nozzle 1, a number of threaded horizontal water outlets are opened, respectively connected to a number of horizontal water spray pipes 2, and a circumferential rotation in the center Adjust the spray head structure of the droplet diameter, on the lower bottom plate 3 of the cylindrical spray head, on the circumference of different diameters from the inside to the outside, a plurality of water spray holes 3a are evenly opened; corresponding to the multiple water spray holes 3a opened on the circumference of different diameters , in the middle of the cylindrical shower head, a multi-circle water spray hole cover is set, that is, a multi-circle rotating ring piece 4 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com