Wheel hub motor arrangement

A wheel hub motor and wheel hub technology, applied in the direction of electromechanical devices, electric vehicles, electrical devices, etc., can solve the problems of short service life, in-wheel motor system load capacity and calibrated power limit, etc., to achieve and firm structure, load and manufacturing dynamic compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

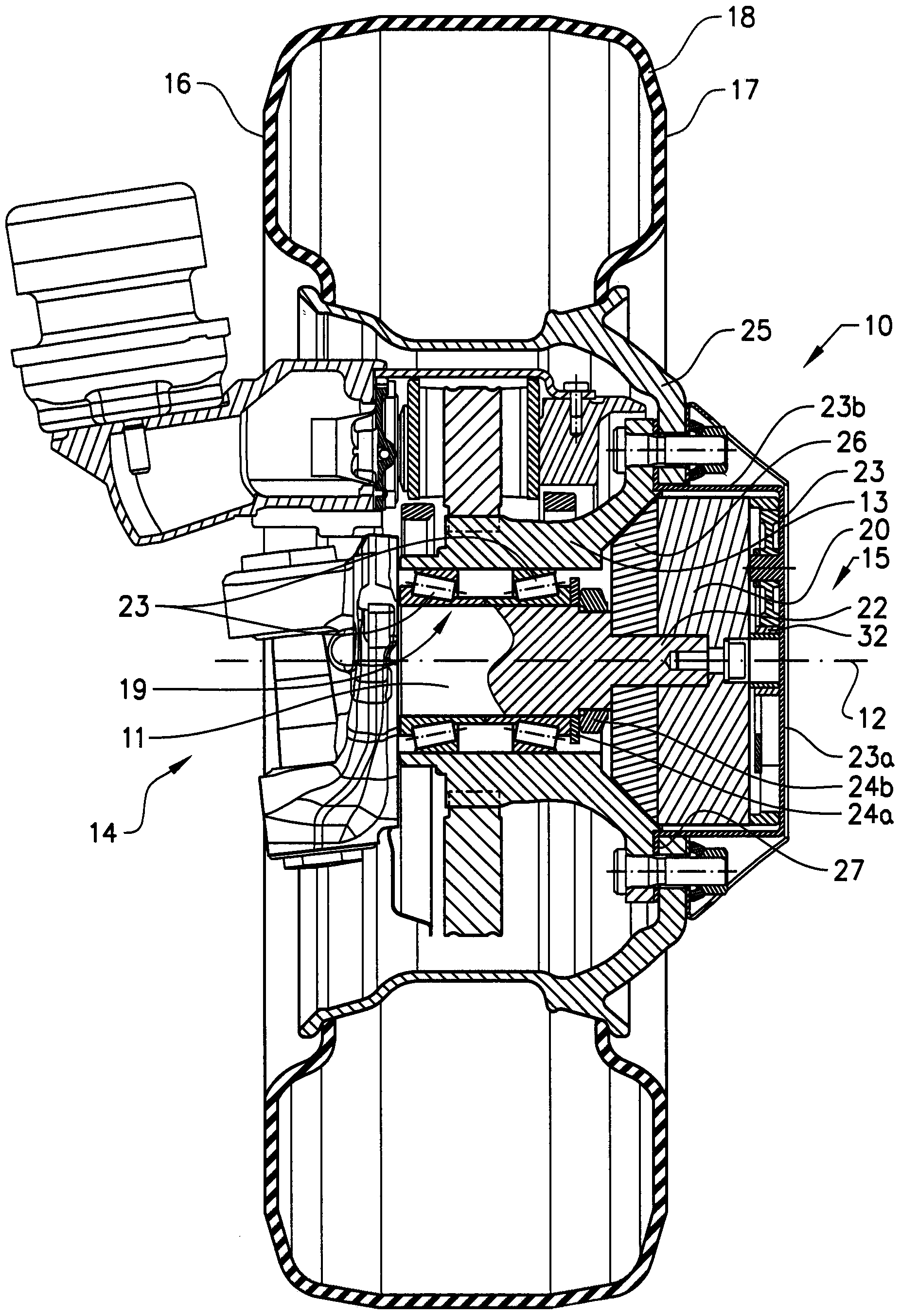

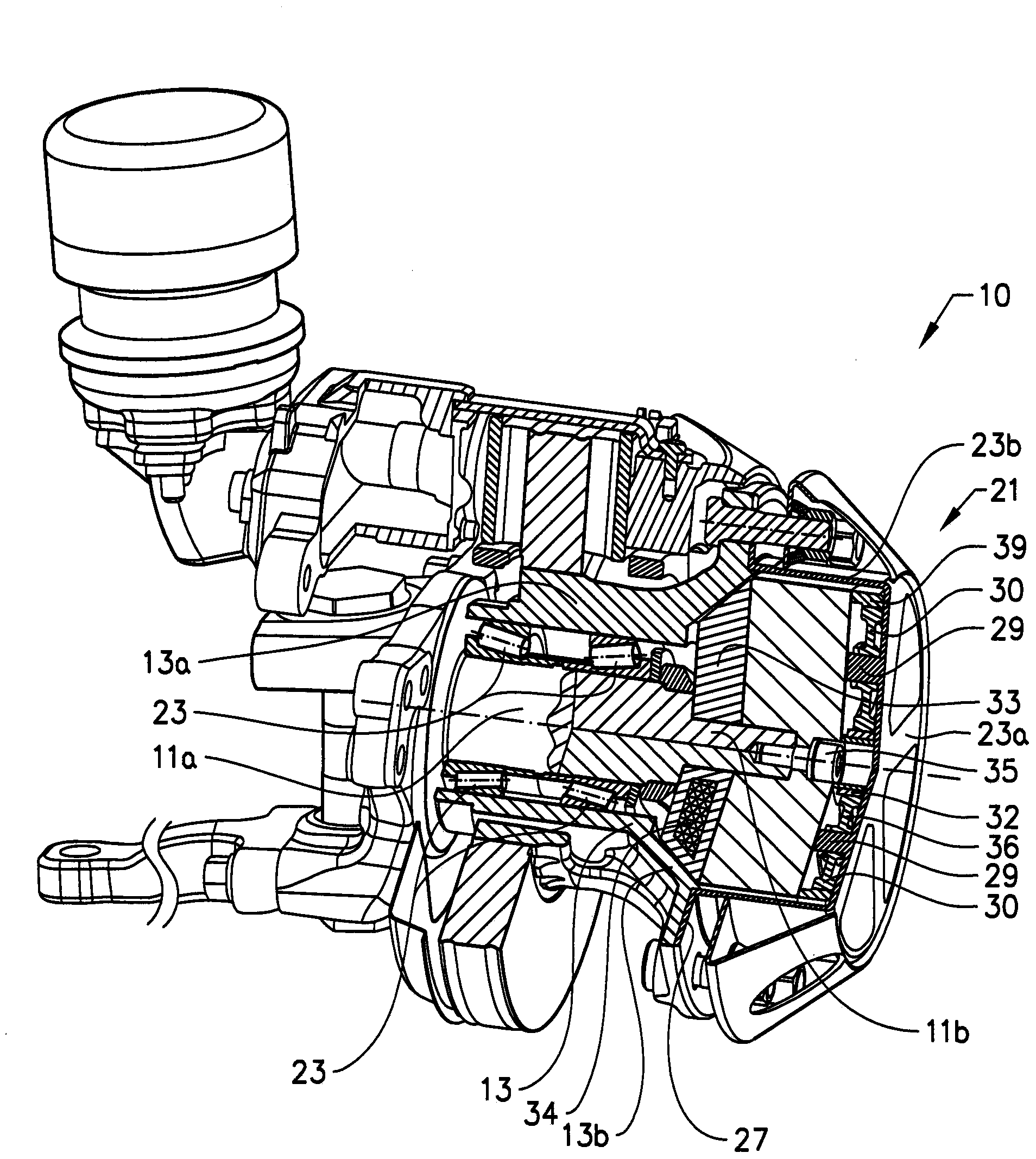

[0043] In the drawings, the same or similar elements are denoted by the same reference numerals. The drawings are schematic diagrams only, not intended to illustrate specific parameters of the invention. Moreover, the drawings are intended to depict only typical embodiments of the invention, and therefore should not be considered as limiting the scope of the invention.

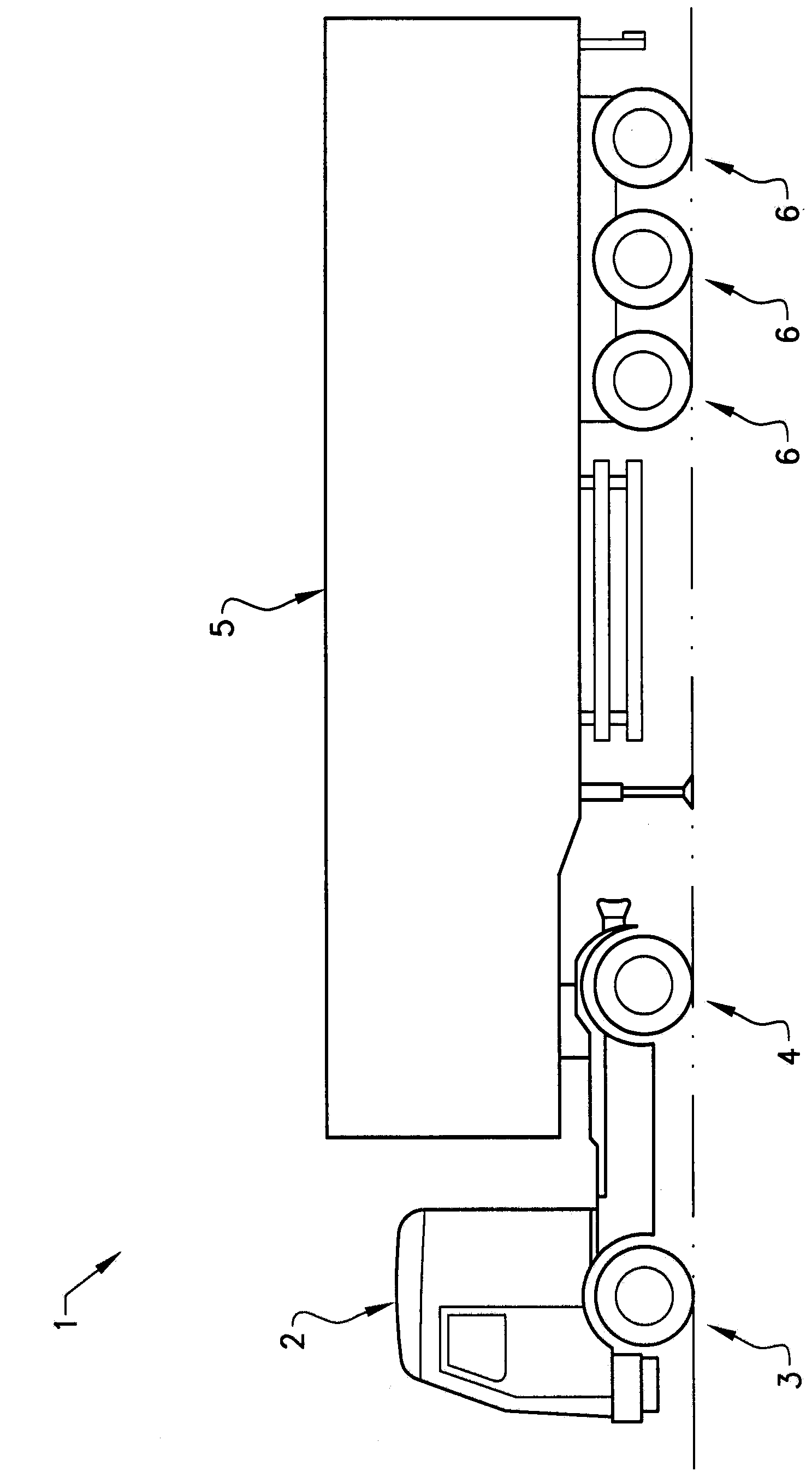

[0044] exist figure 1 , a schematic view of a vehicle 1 that may be equipped with a hub motor (WHM) arrangement according to the invention is shown. Vehicle 1 is a conventional large truck for long-distance towing applications, comprising a tractor 2 (such as a 4X2 truck) with front 3 and rear 4 axles, and a trailer 5 with multiple trailer axles 6 . For example, the rear axle 4 of the tractor 2 can be driven by conventional propulsion, wherein the wheels on each side of the front axle 3 are equipped with a WHM device according to the invention. The front axle 3 can be electrically driven by a WHM device to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com