High-strength alkali-aluminosilicate glass

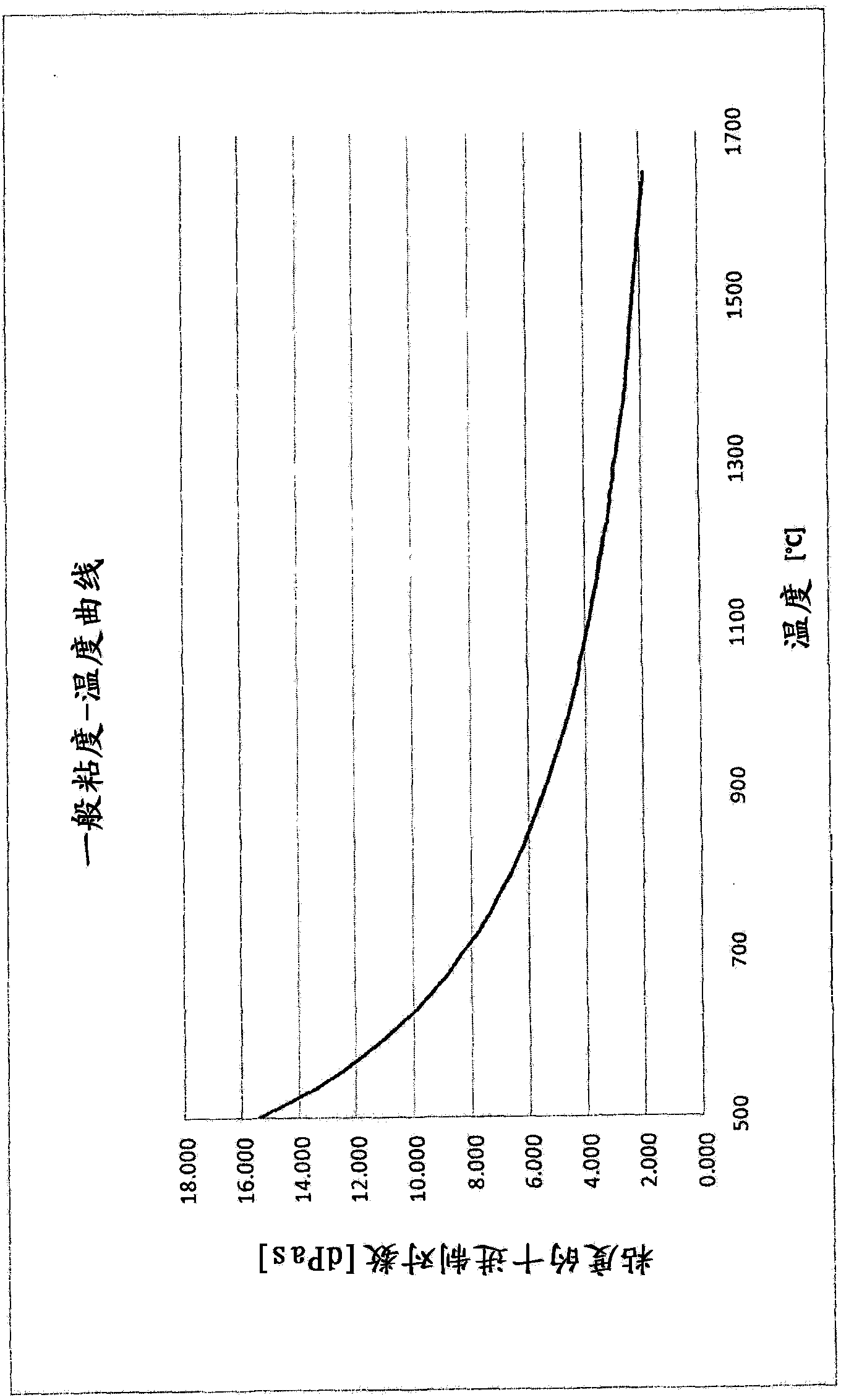

A technology of aluminosilicate glass and alkali metal, which is applied in the fields of instruments, electrical digital data processing, transportation and packaging, etc., and can solve the problem of low liquidus viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

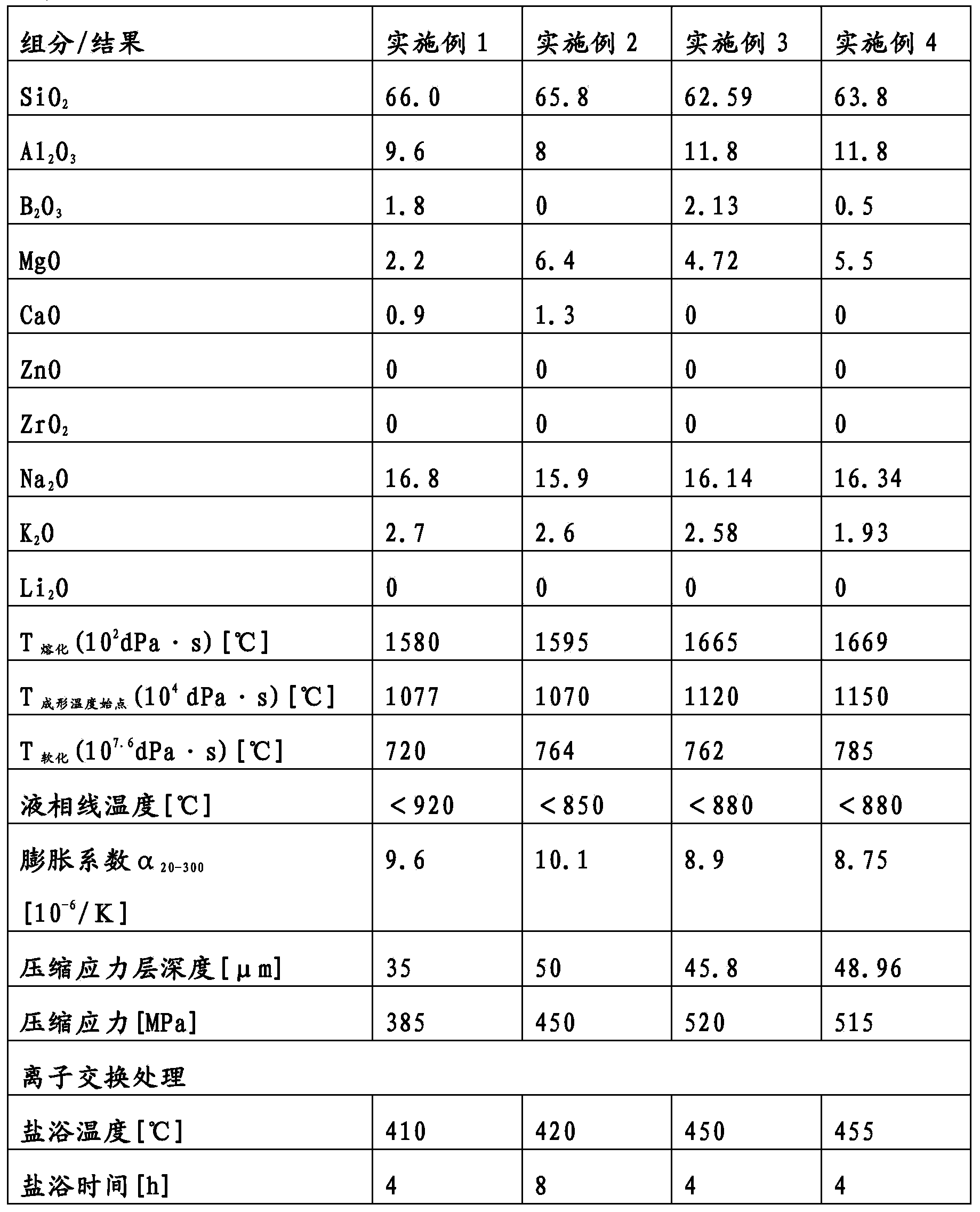

[0064] The glass compositions listed in Table 1 below were melted and refined using high purity feedstock from the mixture in a 2 liter pan, which was directly heated electrically at 1580°C. The molten mass was then homogenized using mechanical agitation.

[0065] The molten mass is then processed into rods or billets.

[0066] The ion exchange treatment is then carried out in an electrically heated pan salt bath furnace. The treatment temperature is selected on the basis of the respectively measured transition temperature of the glass which is less than the transition temperature 90-120K. Ion exchange treatment times vary from 2 to 16 hours.

[0067] The measurement of the surface compressive stress of the glass and the depth of the compressive stress layer (based on birefringence) were determined by using a polarizing microscope (Berek compensator) on a section of the glass. The compressive stress of the glass surface was calculated from the measured birefringence assumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com