Reflection layer system for solar applications and method for the production thereof

A reflective layer and solar energy technology, which is applied in the field of reflective layer systems, can solve the problems of increased material consumption, inability to use multiple applications, high material costs, etc., and achieve the effects of cost saving, material saving, and strong adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

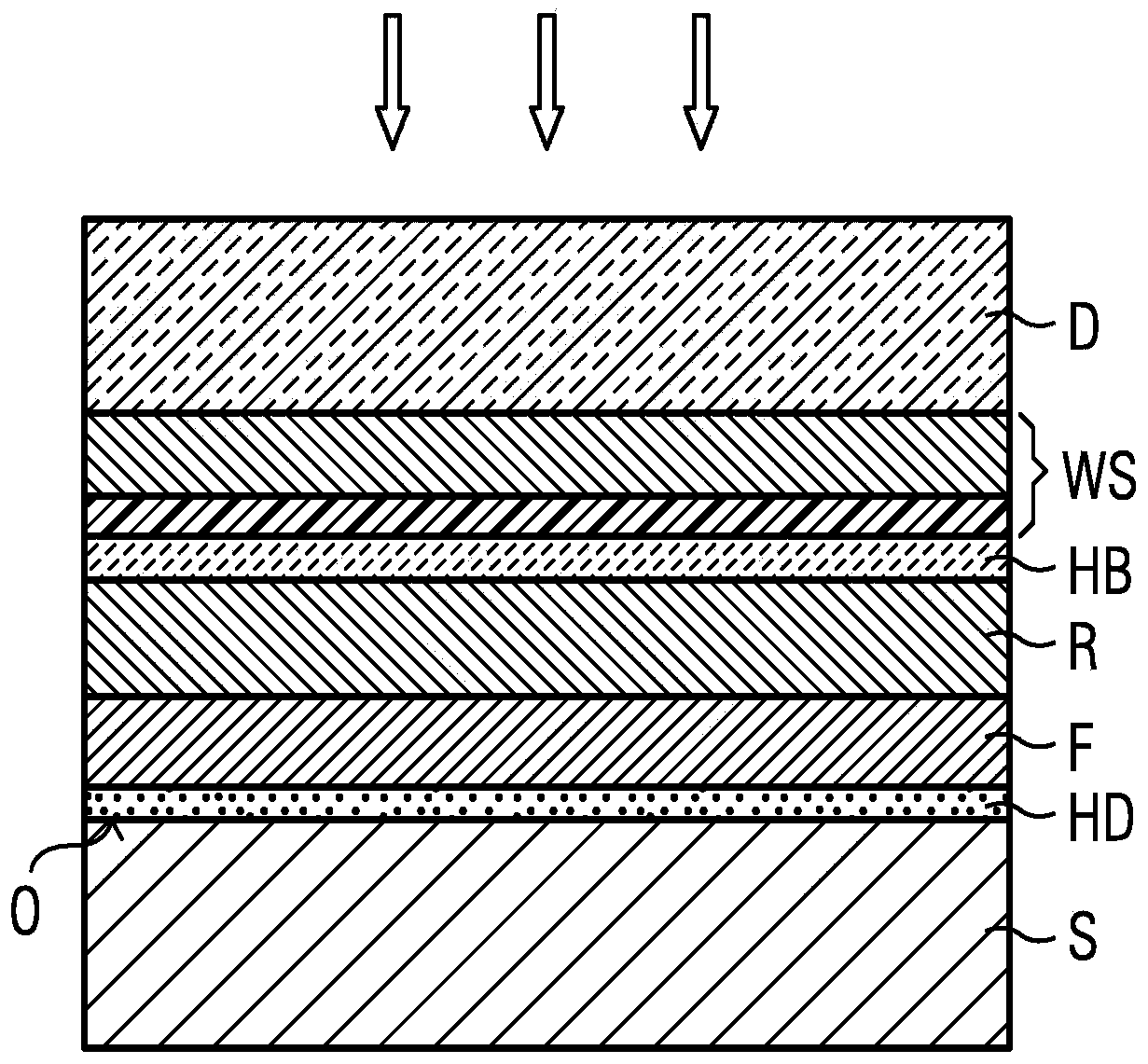

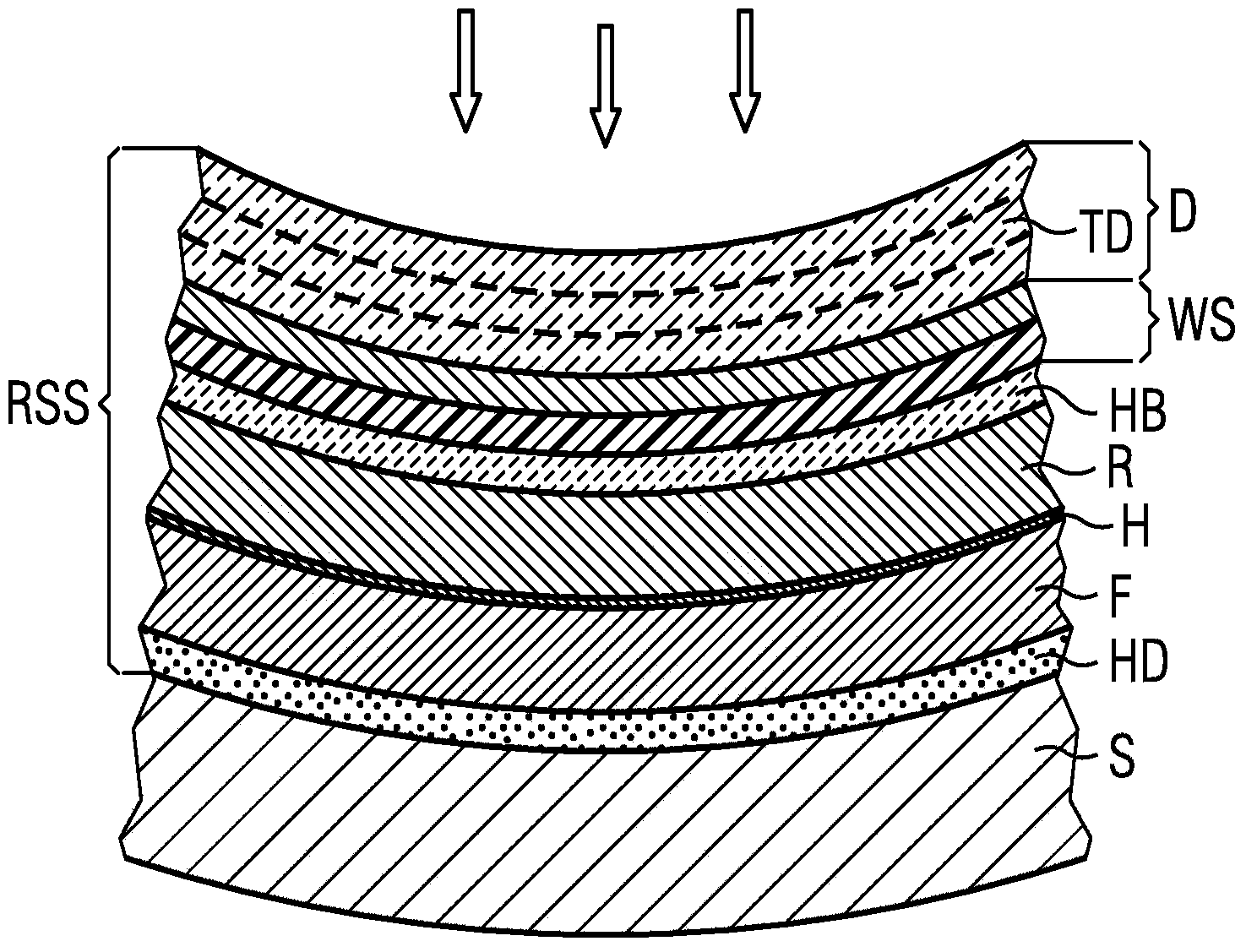

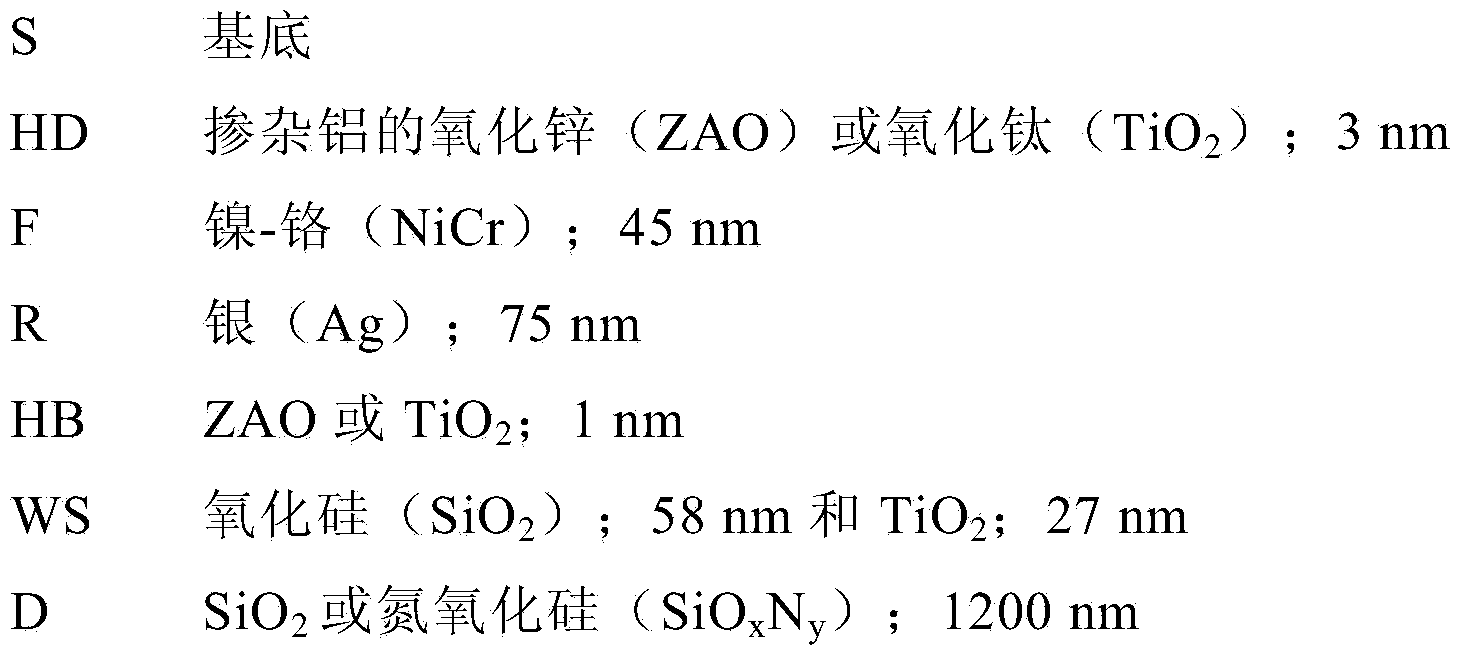

[0043] in accordance with figure 1 In an embodiment, the reflective layer system according to the invention has the following layer structure, which, viewed from the substrate upwards, has the layer thicknesses described below in the direction of light incidence (identified by the arrow):

[0044]

[0045] According to ISO 9050:2003, a total solar reflection of greater than 96% is obtained with such a front side mirror reflector system.

[0046] To produce the layer system, the layers are successively deposited by magnetron sputtering on a correspondingly carefully polished, washed and dried substrate S, for example float glass. Alternatively, a combination of magnetron sputtering with other PVD methods such as e-beam evaporation, or CVD or PECVD methods or another wet chemical coating method is also feasible.

[0047] The substrate S may optionally be subjected to a plasma pretreatment in vacuum prior to coating by sputtering. For this purpose, for example, the 2-5 x 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com