Four-wheel-driven three-row corn harvester with front husking machine

A four-wheel drive, three-row corn technology, applied in the field of machinery, can solve the problems of easy to fall into the land, large volume and mass, poor field passing performance, etc., to improve the reliability and adaptability of use, broad market prospects, and ear picking performance. superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

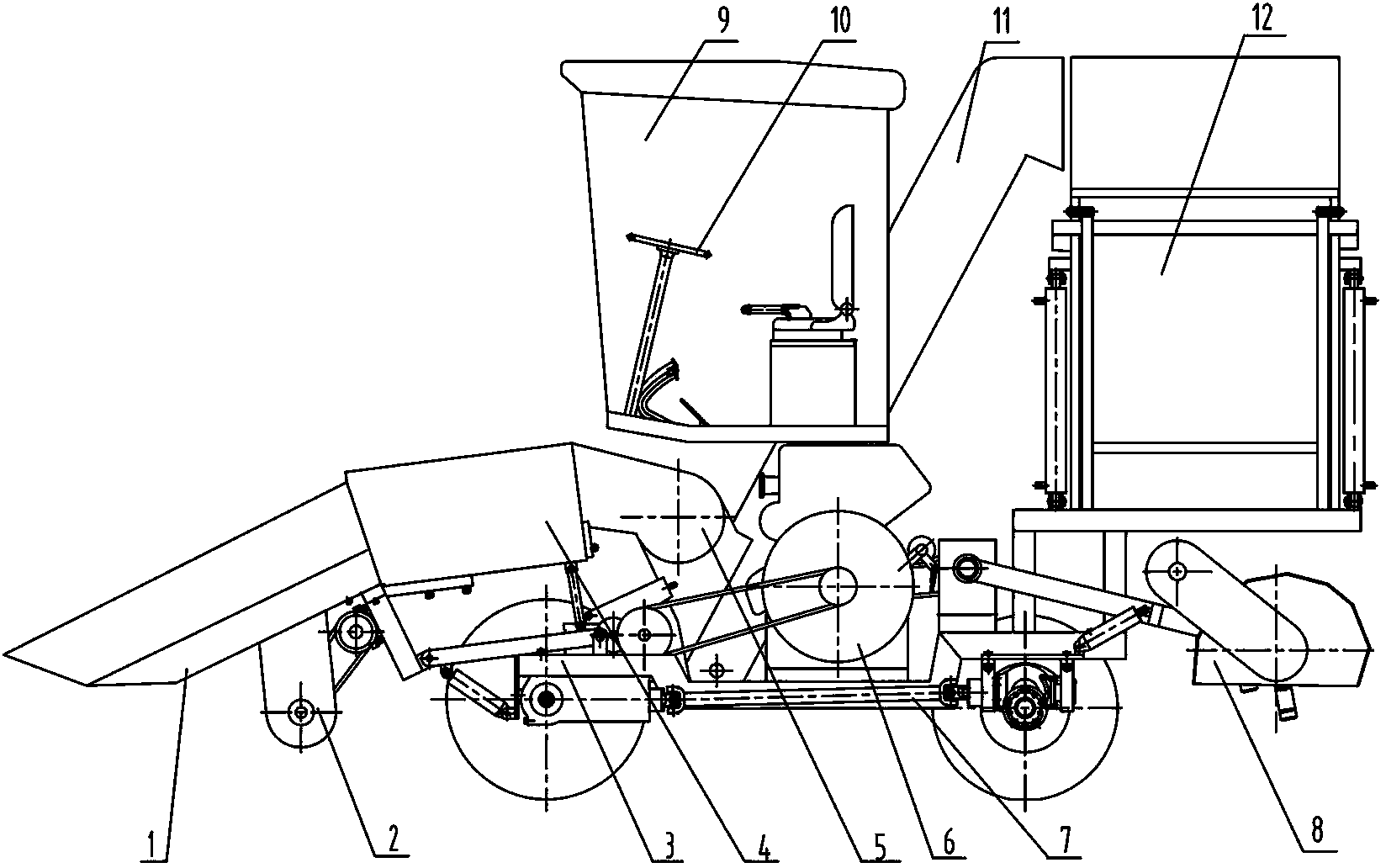

[0010] Attached below figure 1 Further describe the specific implementation of a three-row corn harvester with four-wheel drive at the front of the peeling machine of the present invention: start the diesel engine (6), and drive the whole machine to walk by controlling the power of the diesel engine (6) through the operating mechanism (10) , when it is necessary to harvest corn, the header (1), peeling device (4), auger (5), and elevator (11) are controlled by the operating mechanism (10), and when the corn passes through the header (1), The header (1) separates the corn ears from the corn stalks and transports the corn ears to the peeling device (4). The peeling device (4) peels the corn ears and transports them to the auger (5). The auger (5) will Corn stalks are transported to the right side and transported to the grain storage box (12) through the elevator (11); the corn stalks after picking the ears pass through the stalk cutting device (2) and are cut into small knots an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com