Patents

Literature

32results about How to "The whole machine is compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

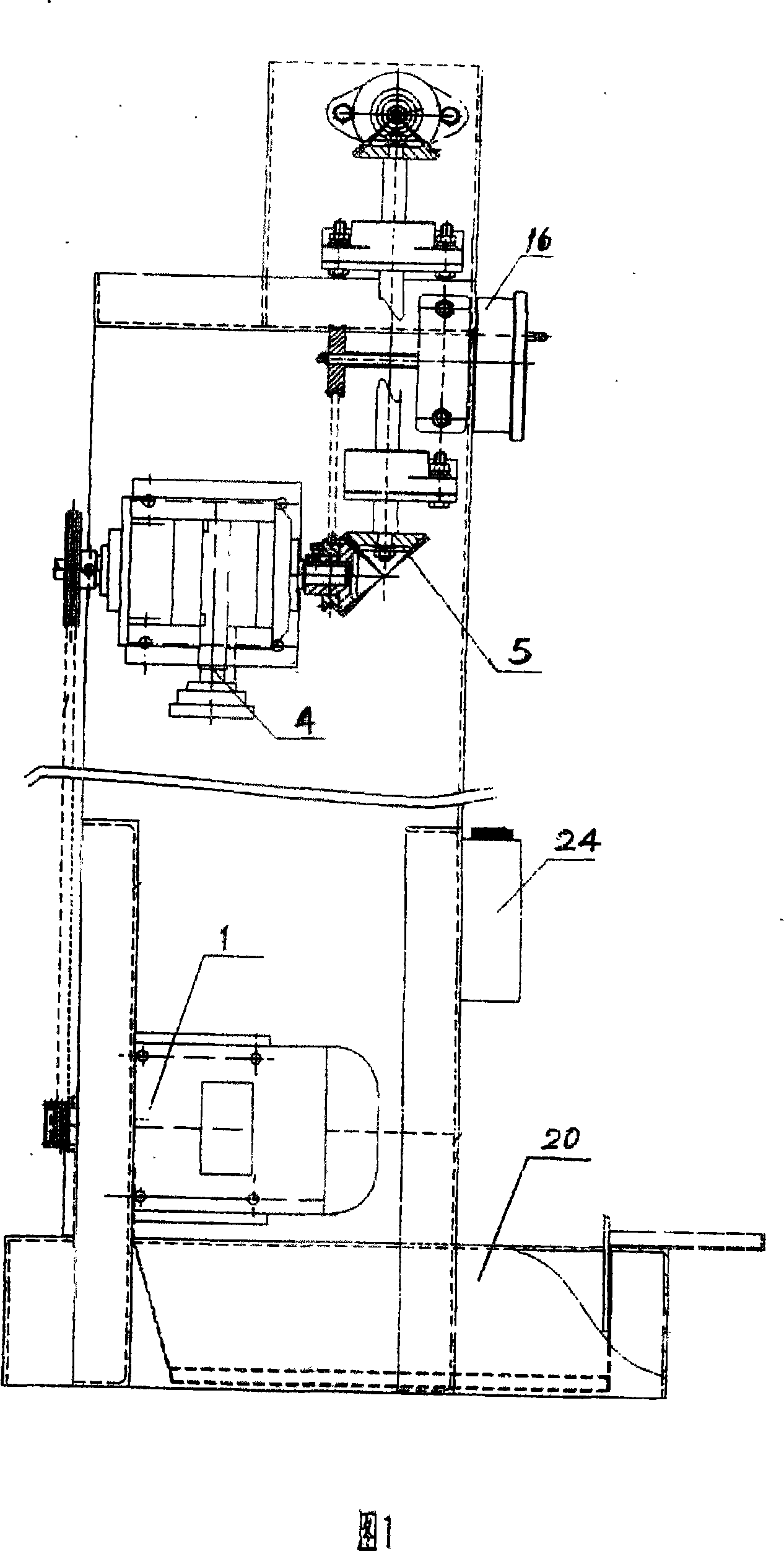

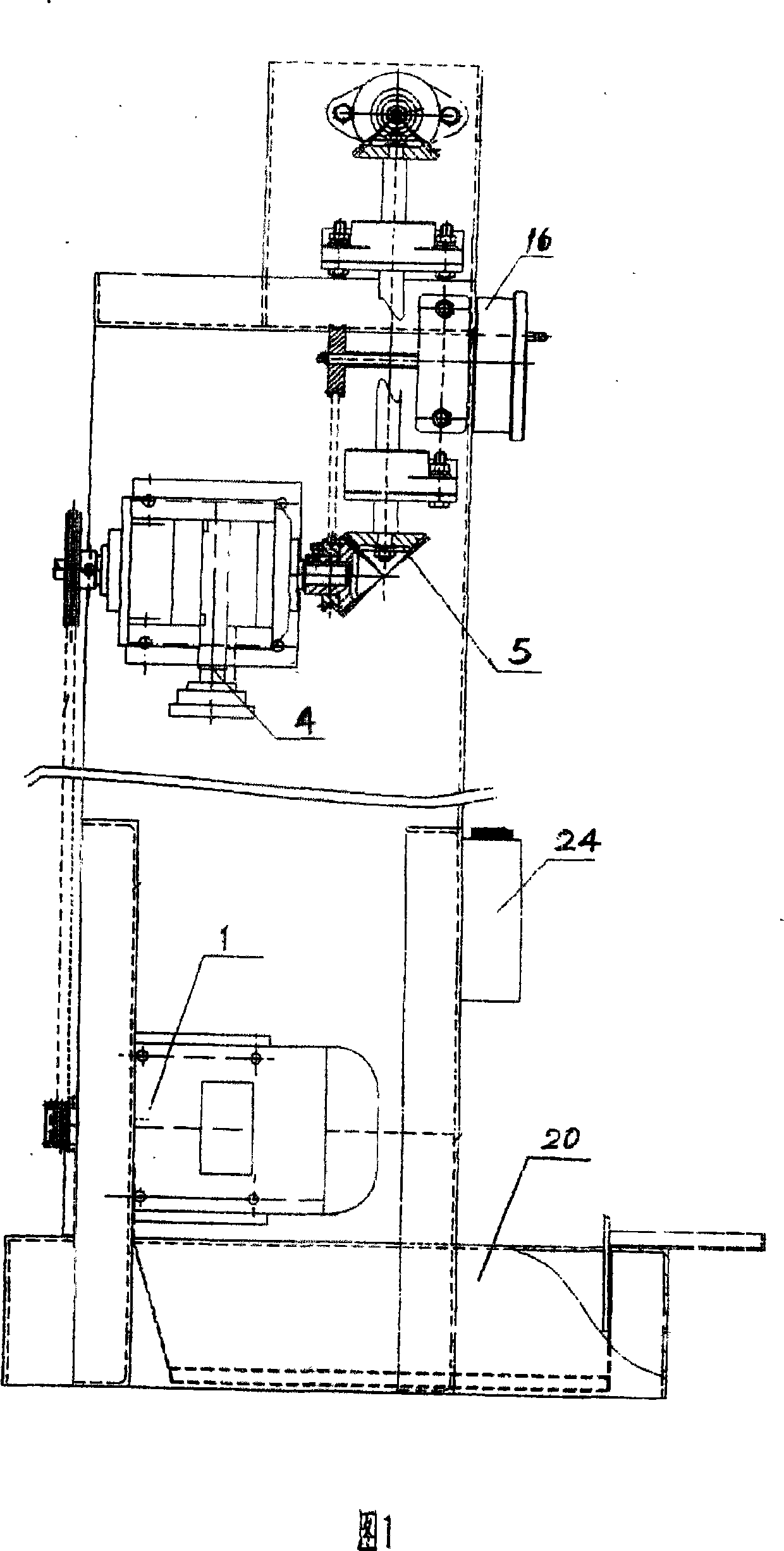

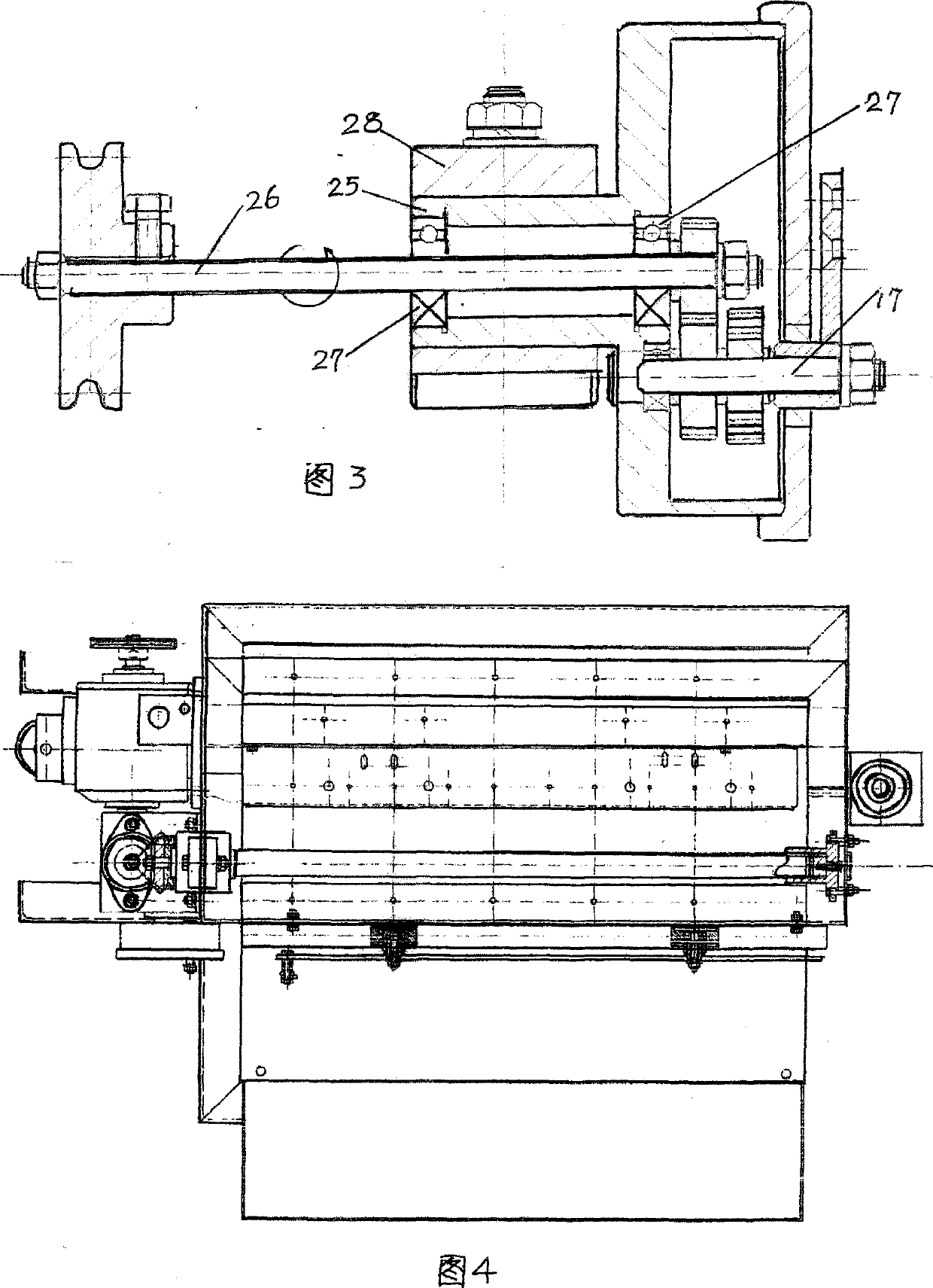

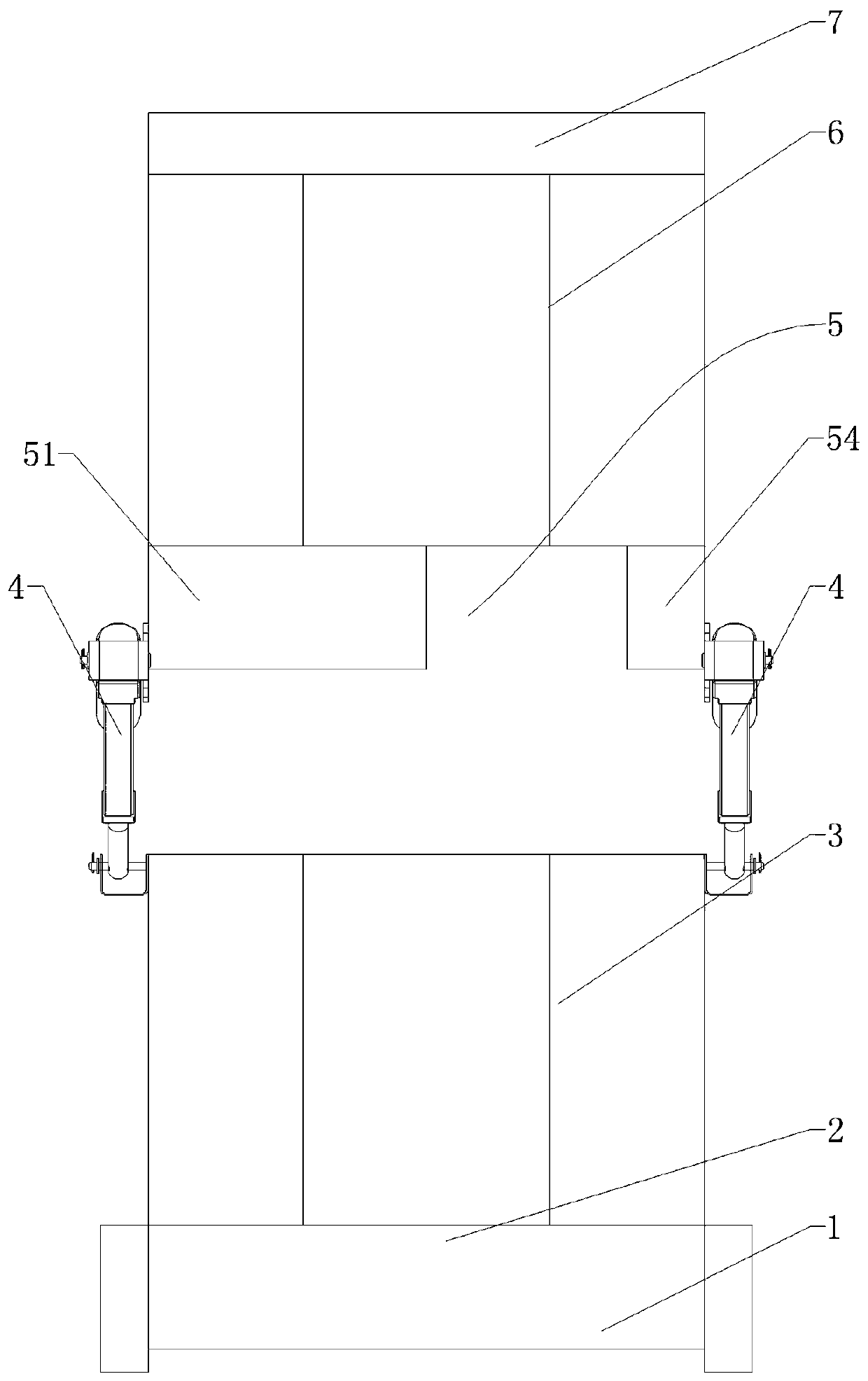

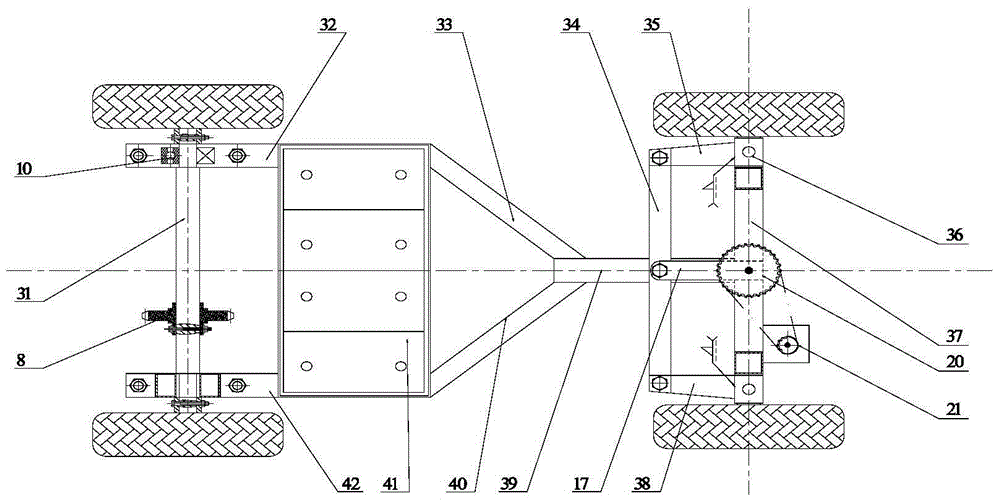

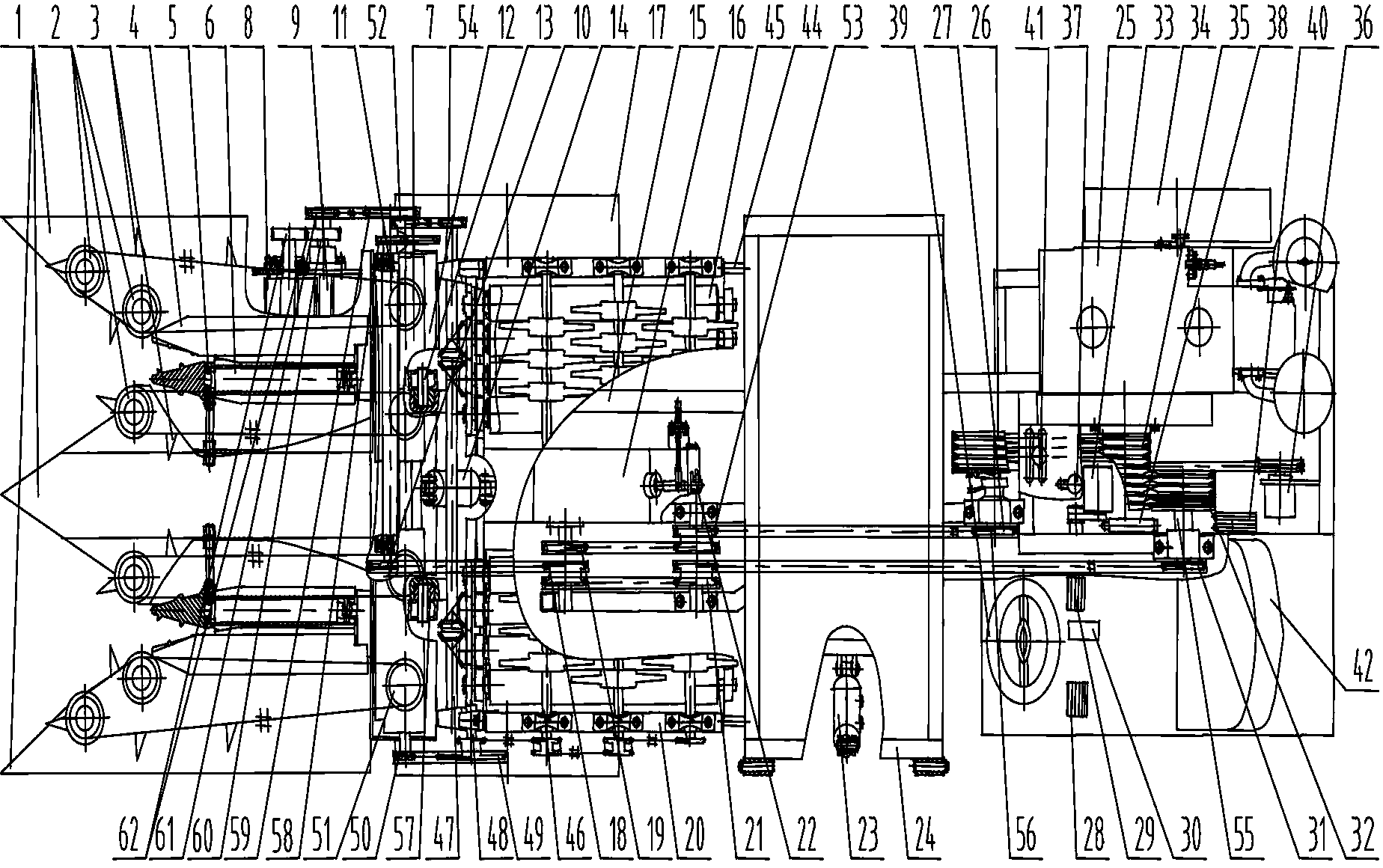

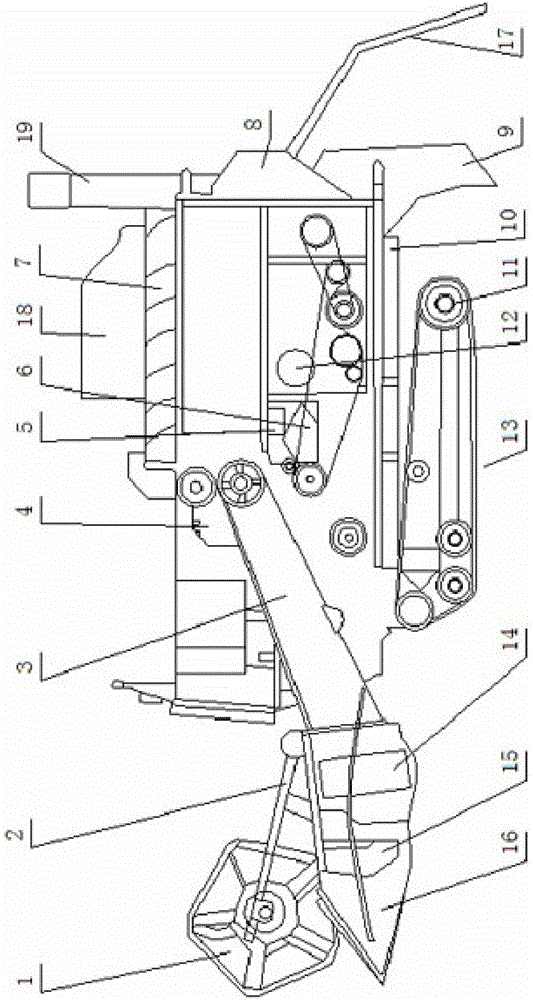

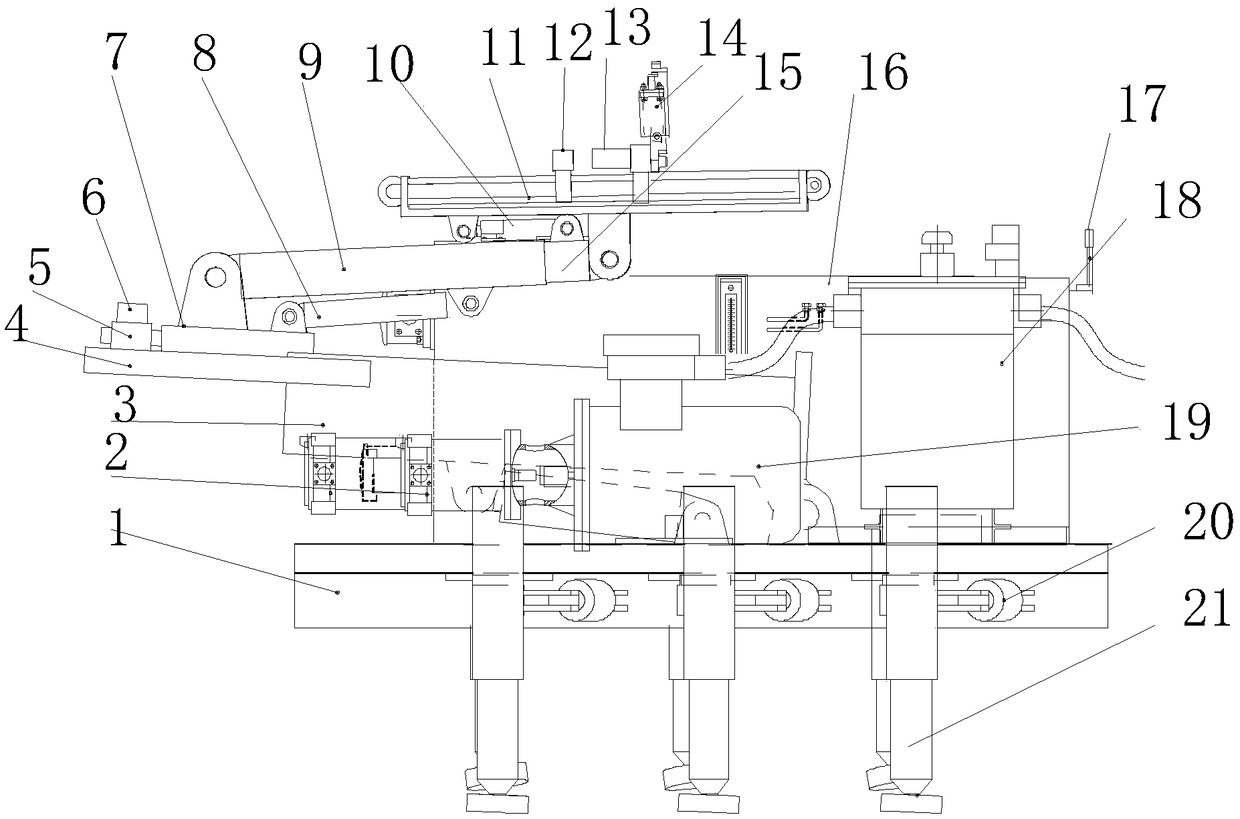

Fertilizer applying, soil grabbing and earthing-up method

ActiveCN104365246AReduce labor intensityIncrease productivityPlantingFertiliser distributersEngineeringTransmission system

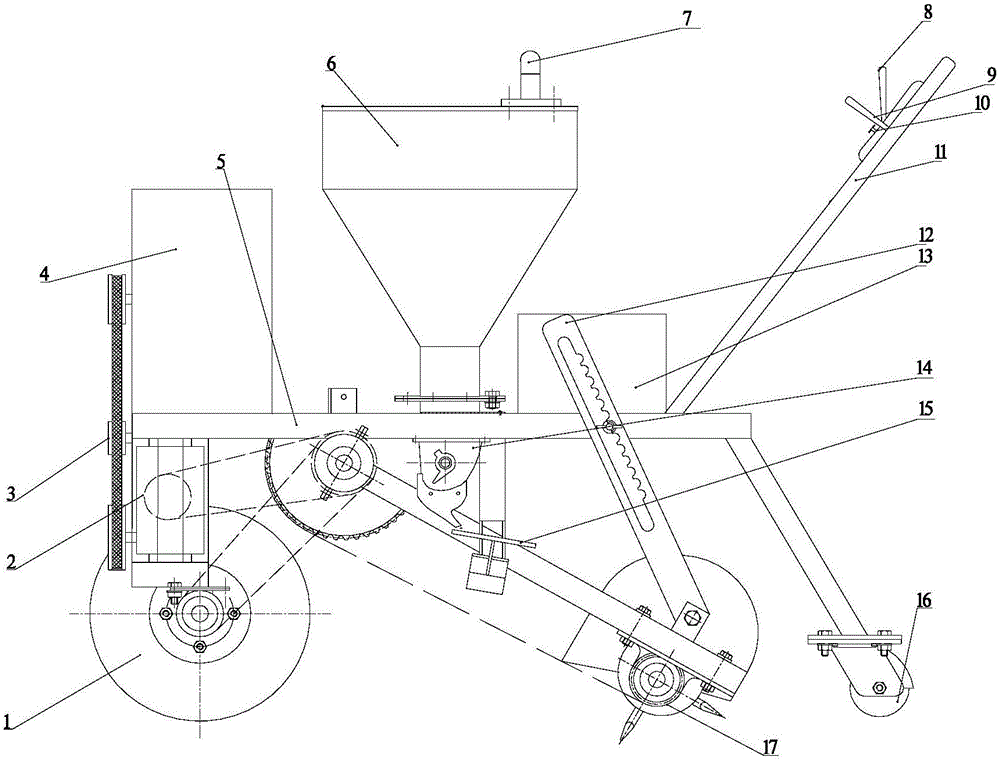

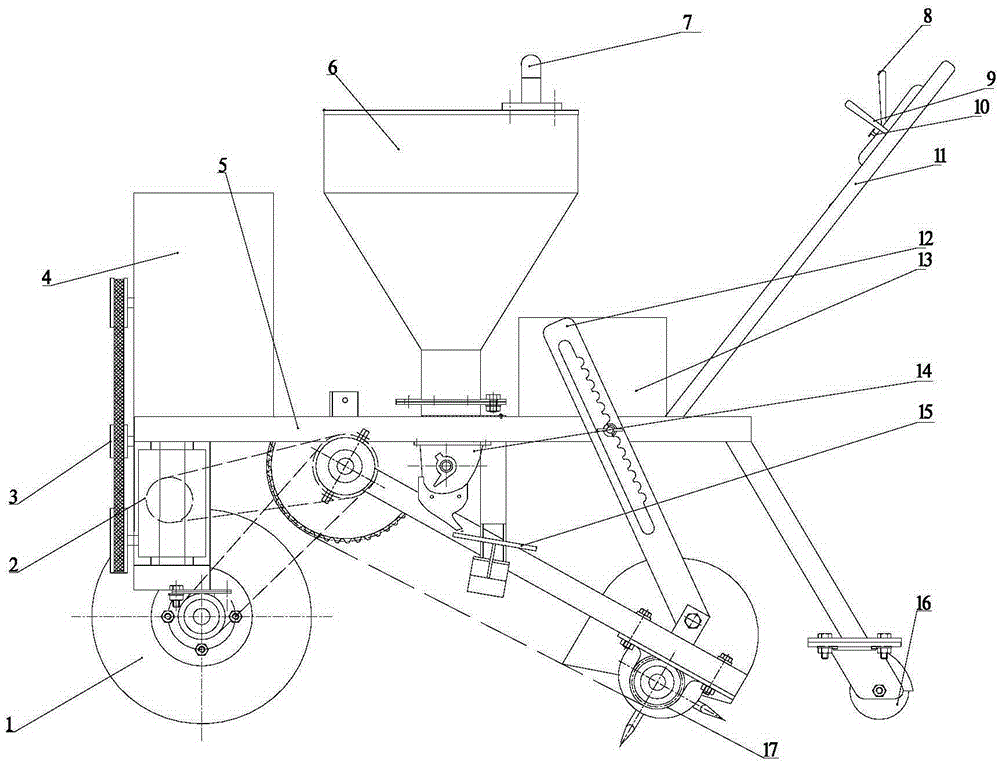

The invention discloses a fertilizer applying, soil grabbing and earthing-up method. A fertilizer applying, soil grabbing and earthing-up machine is adopted to achieve fertilizer applying, soil grabbing and earthing-up at the same time, and comprises a frame (5), a driving and travelling system, a transmission system, a fertilizing system, a soil loosening and earthing-up system and an operating system. The driving and travelling system, the transmission system, the fertilizing system, the soil loosening and earthing-up system and the operating system are arranged on the frame. The fertilizing system is capable of controlling fertilizer discharging speed and fertilizer scattering width, and the soil loosening and earthing-up system is capable of adjusting the soil loosening depth. The fertilizer applying, soil grabbing and earthing-up method is easy to implement, integrates a fertilizer applying function with a soil loosening and earthing-up function, and is high in working efficiency.

Owner:HUNAN AGRICULTURAL UNIV

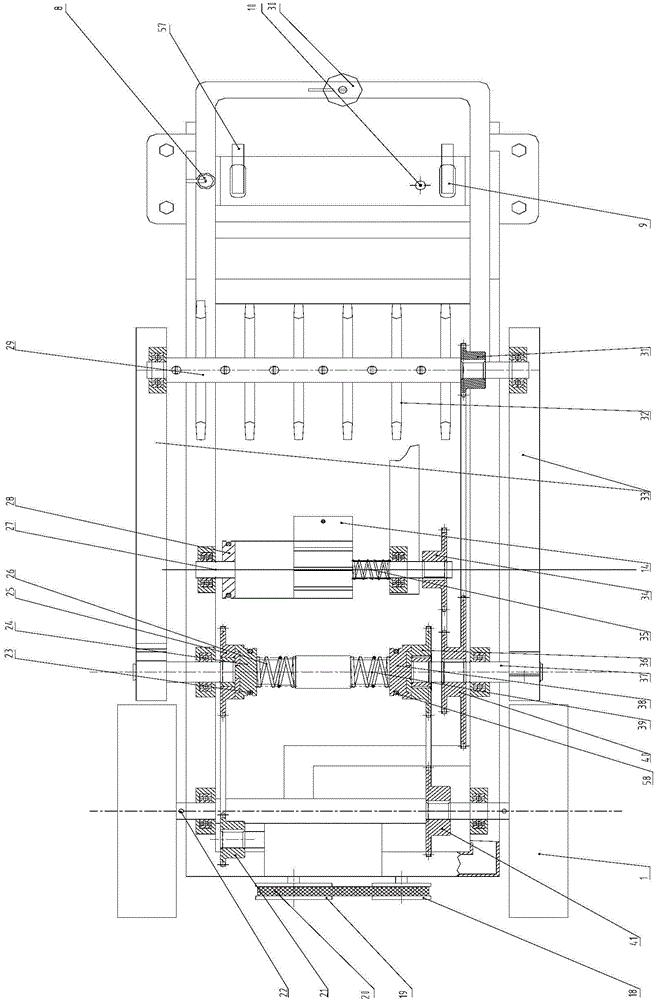

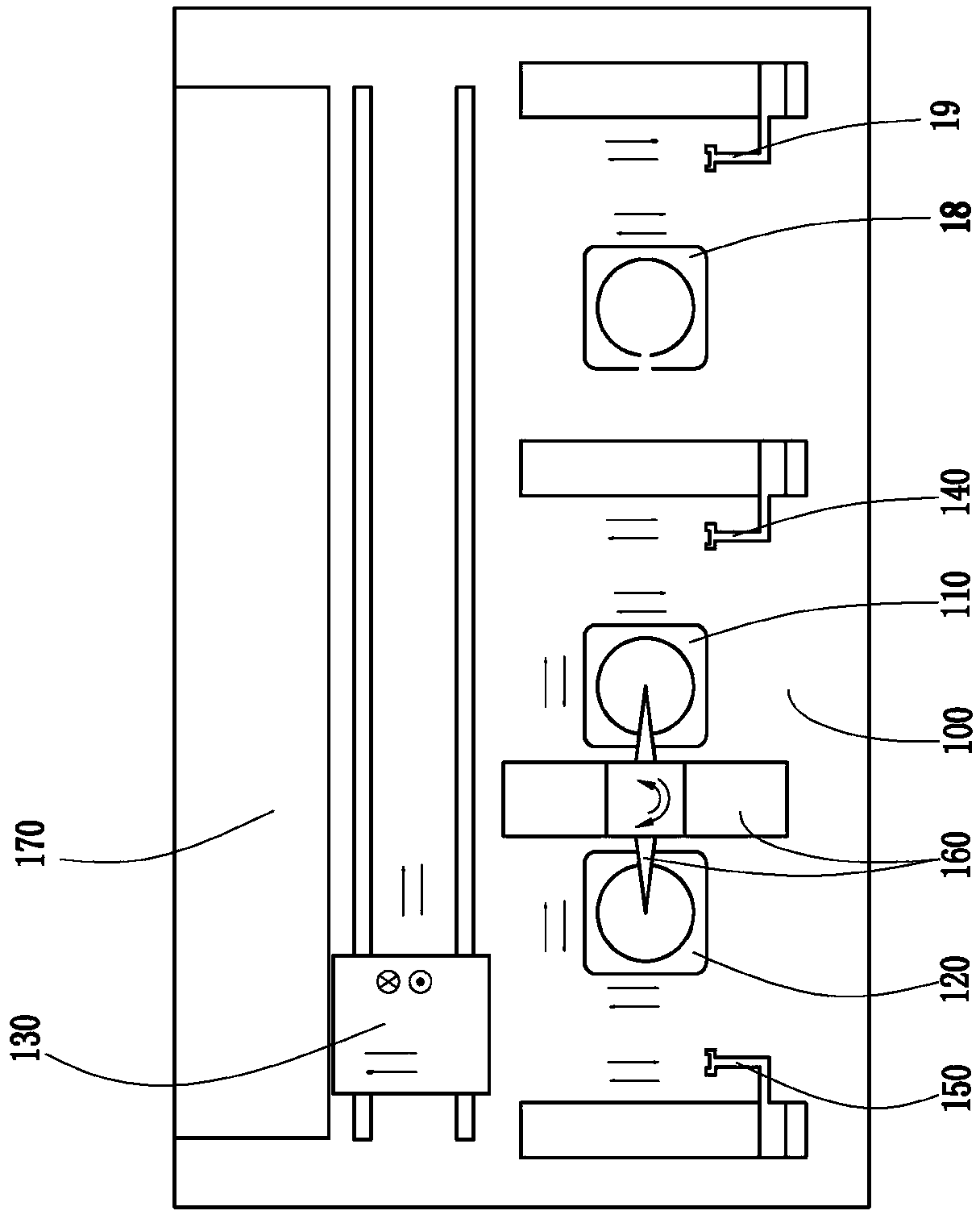

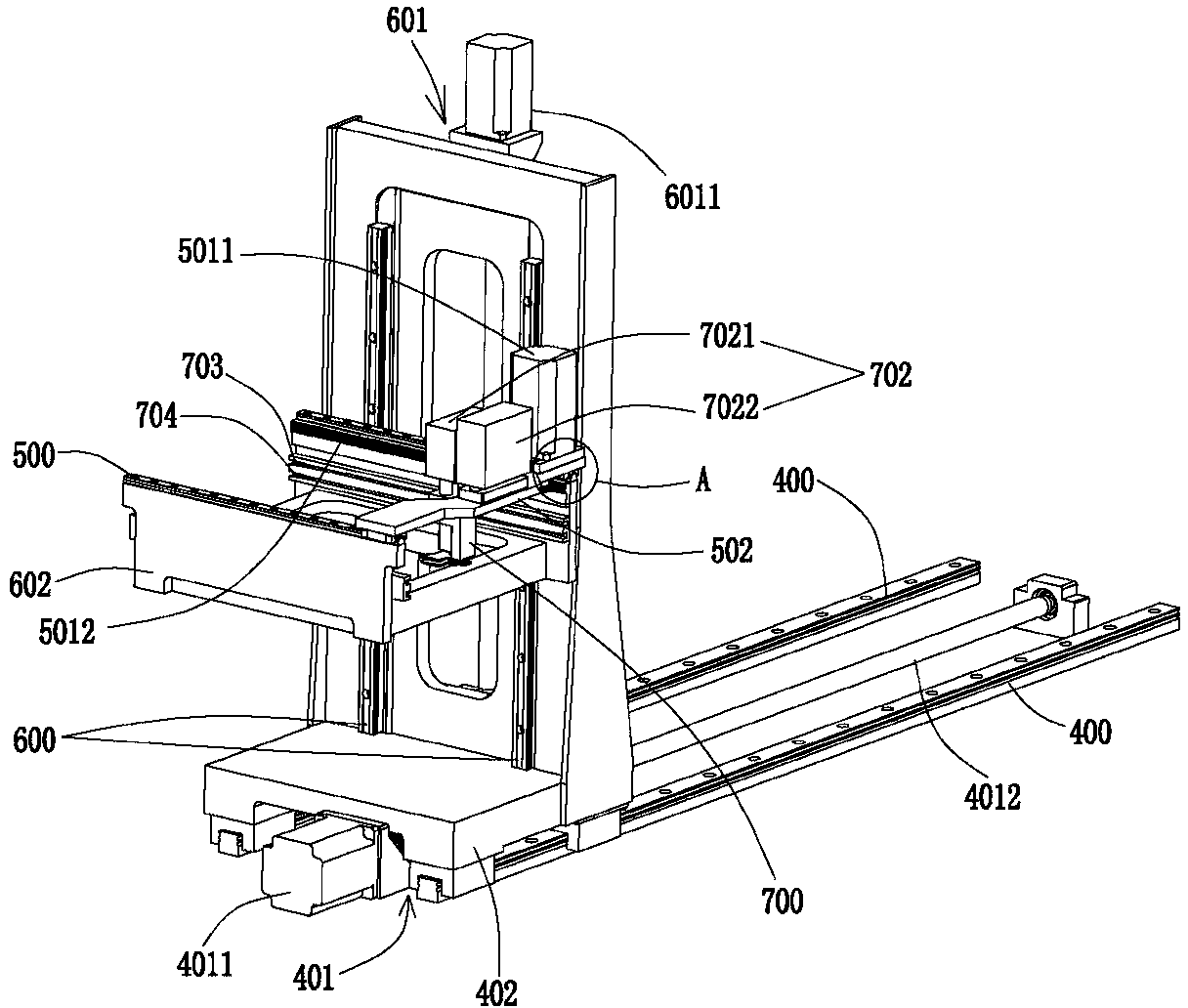

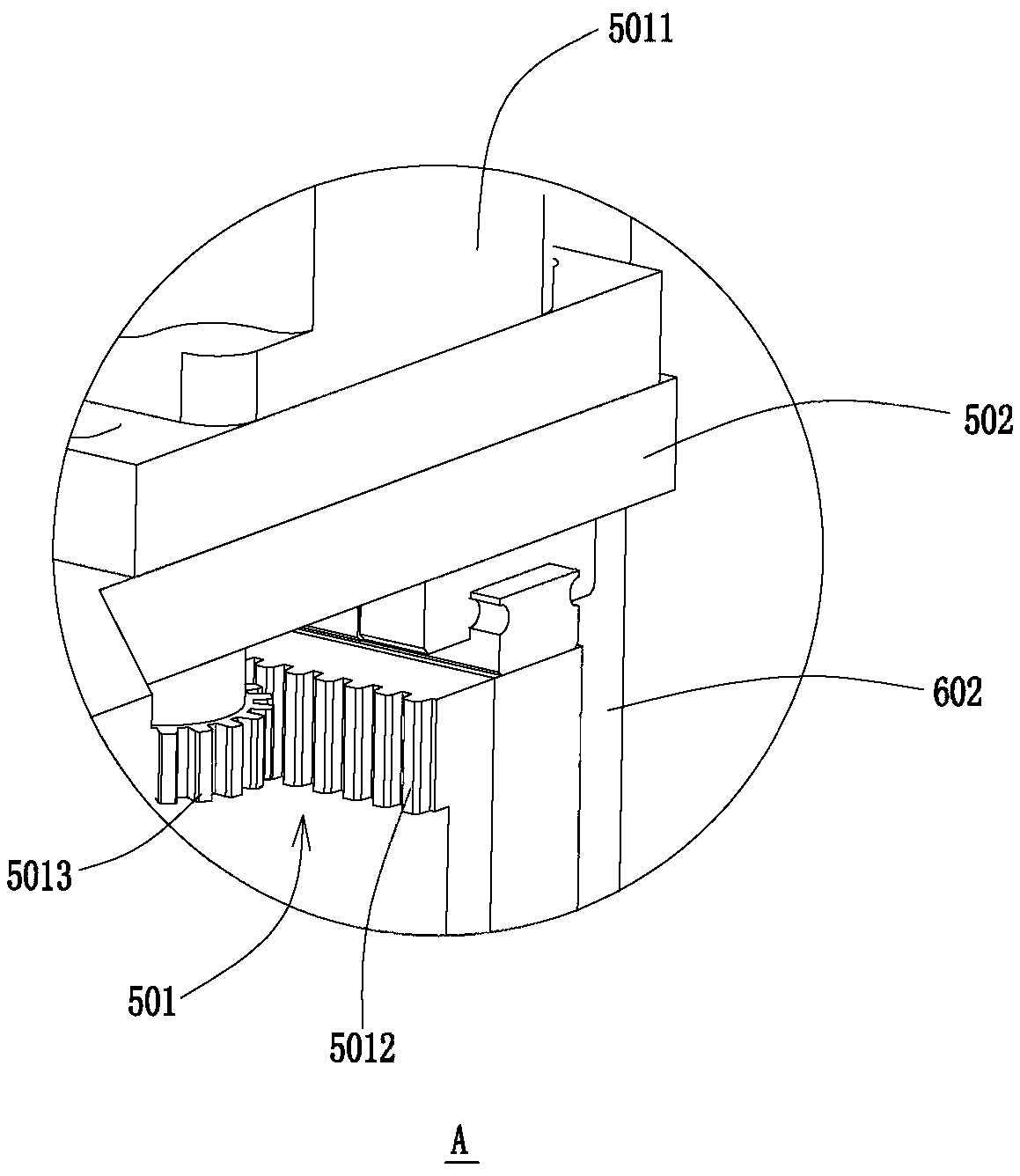

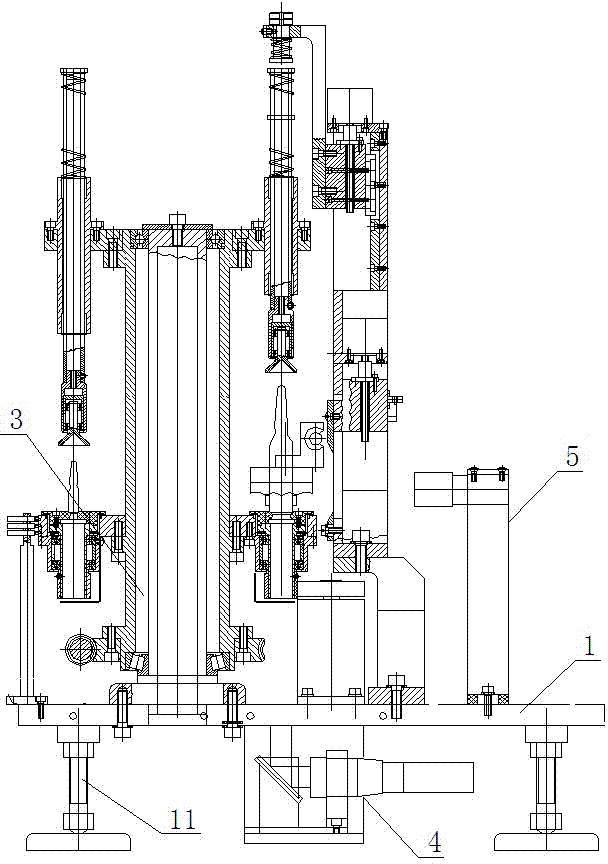

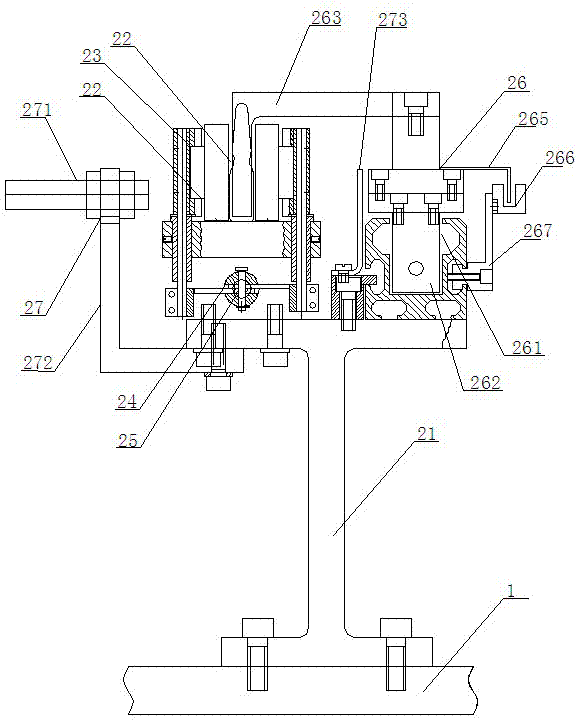

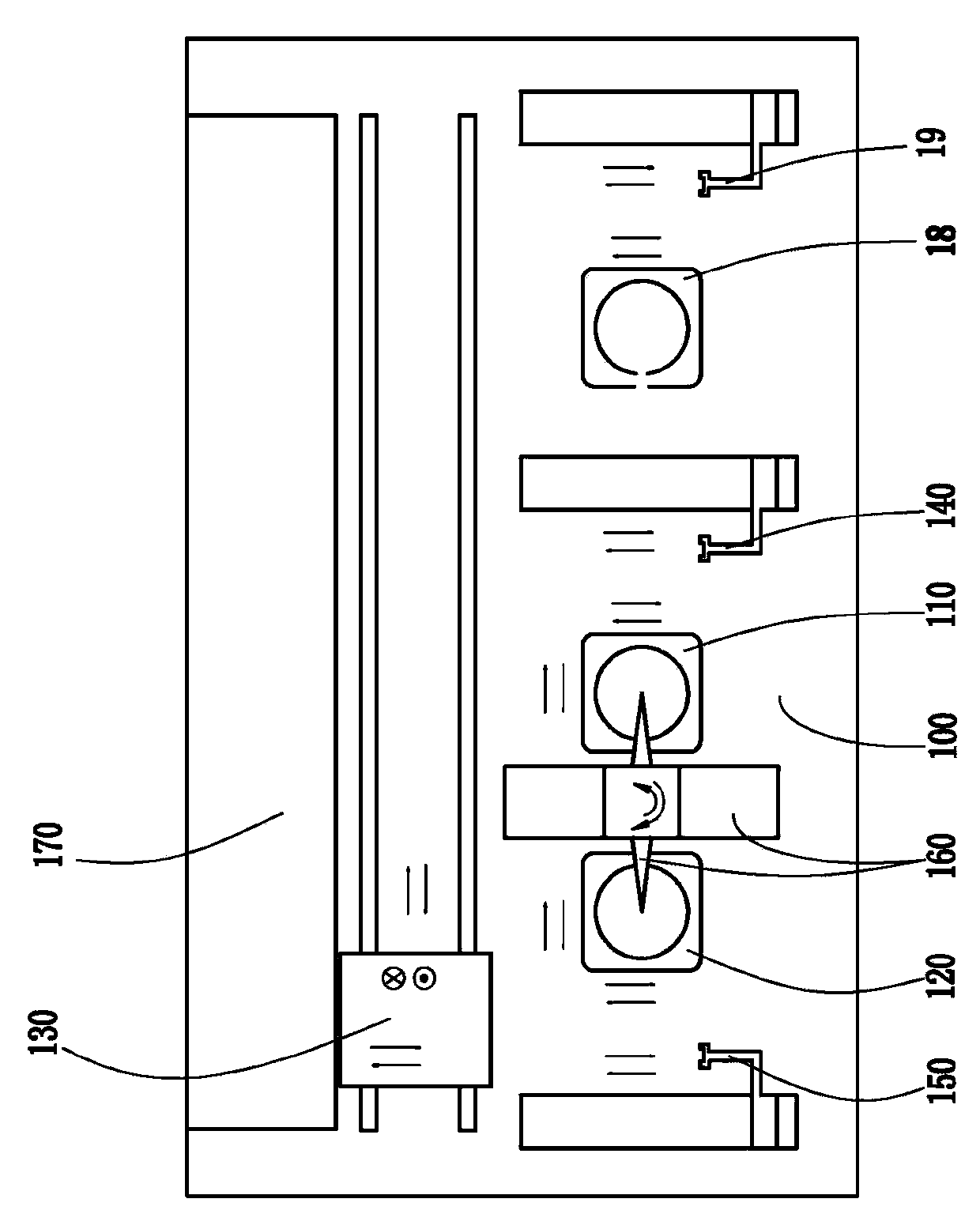

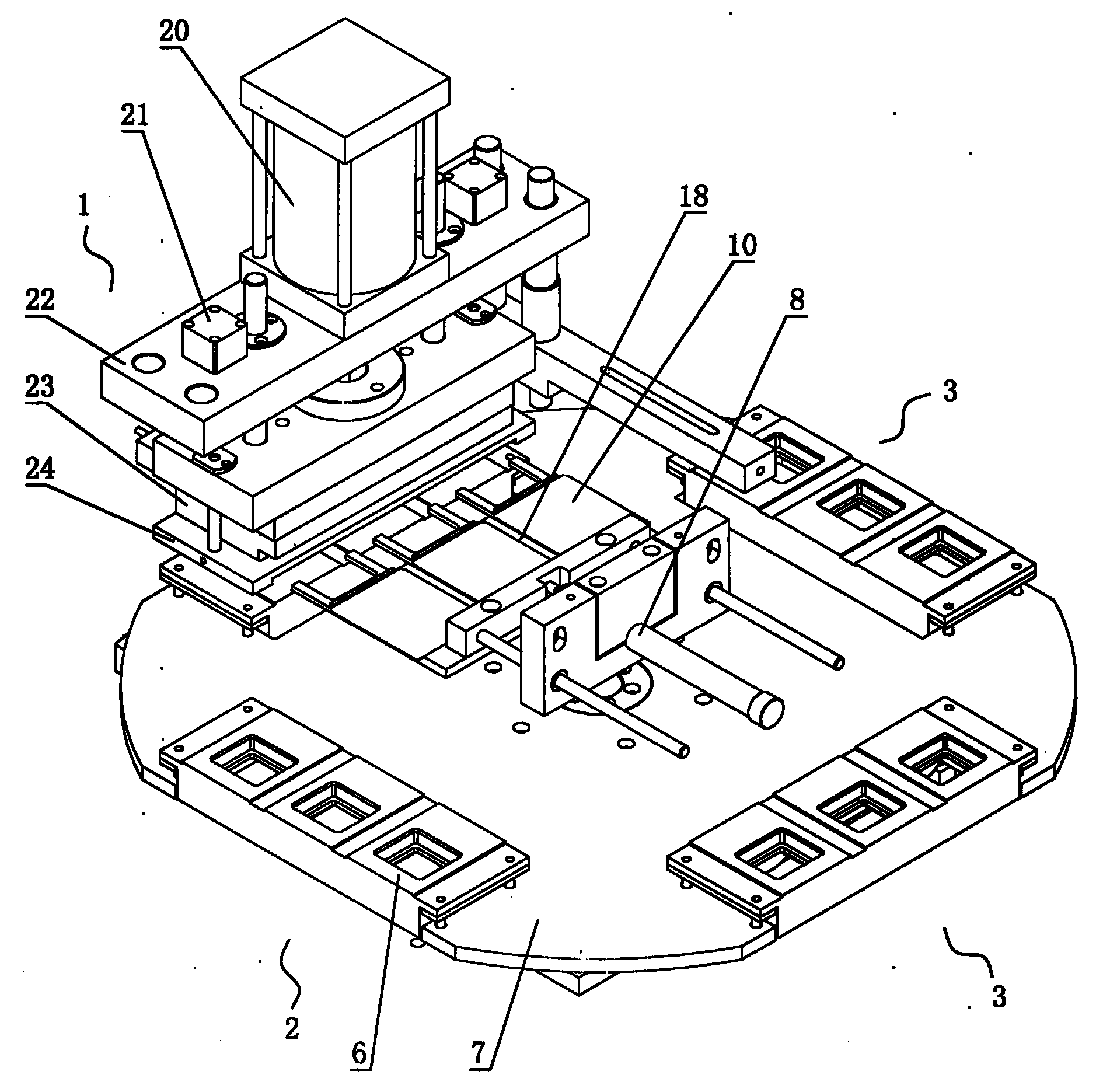

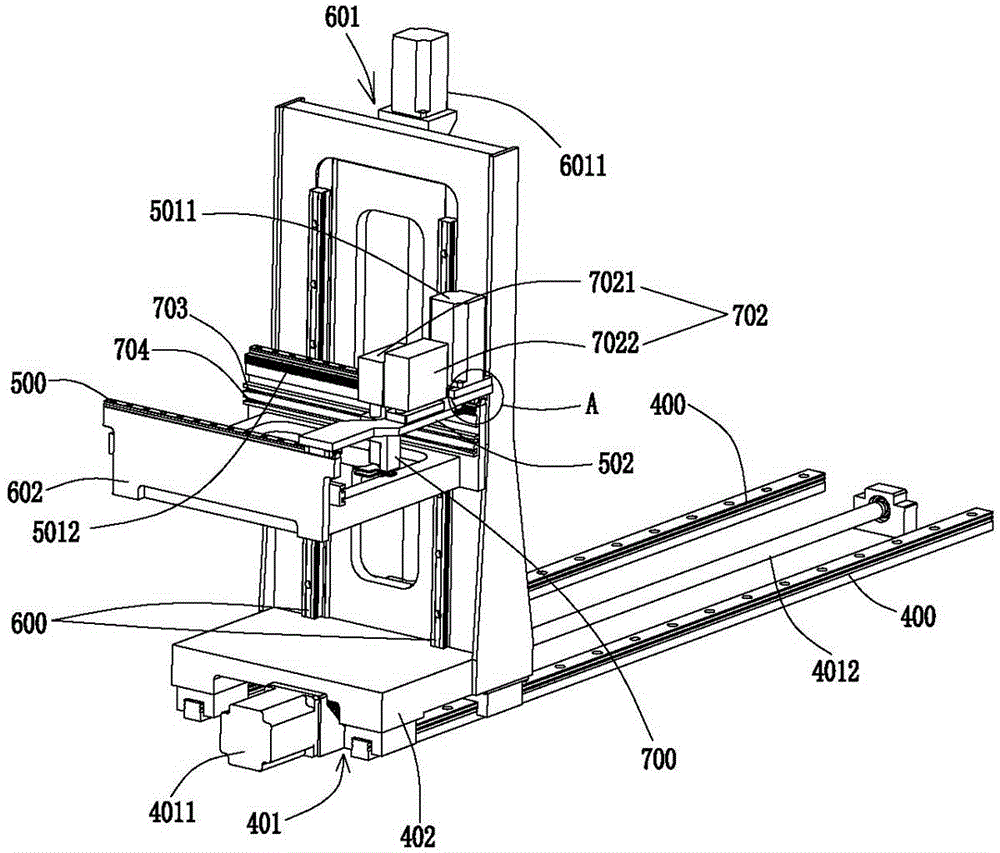

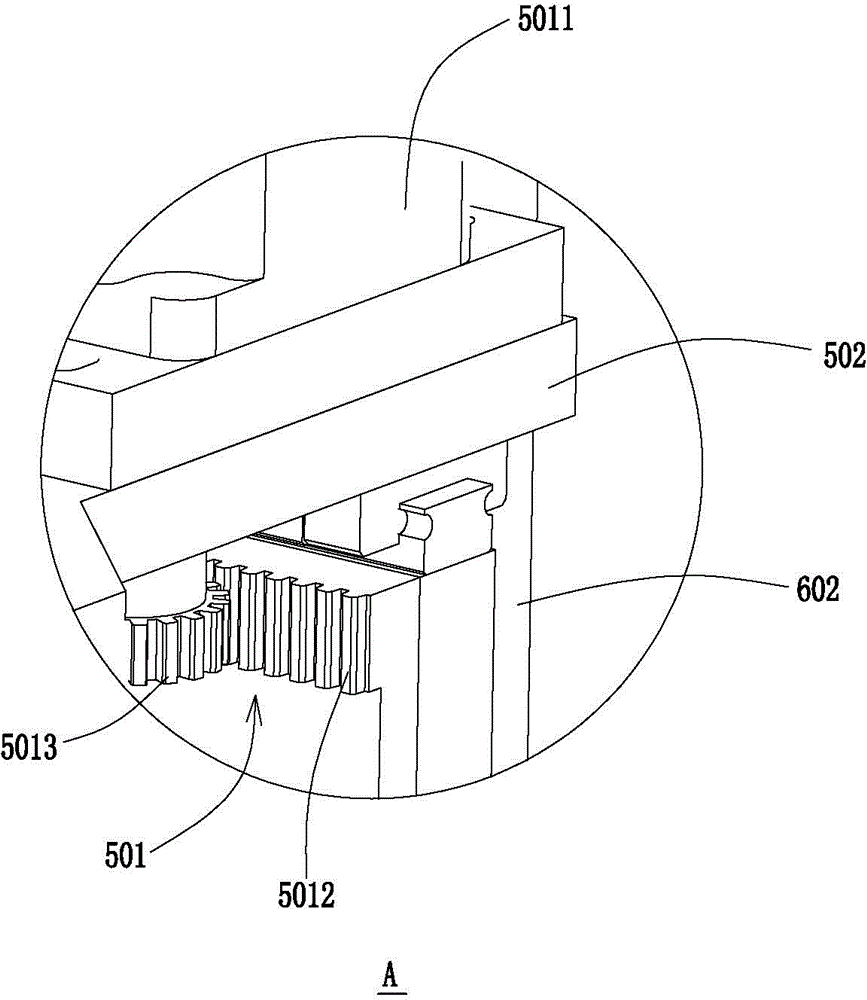

Full automatic crystalline grain detection and sorting all-in-one machine

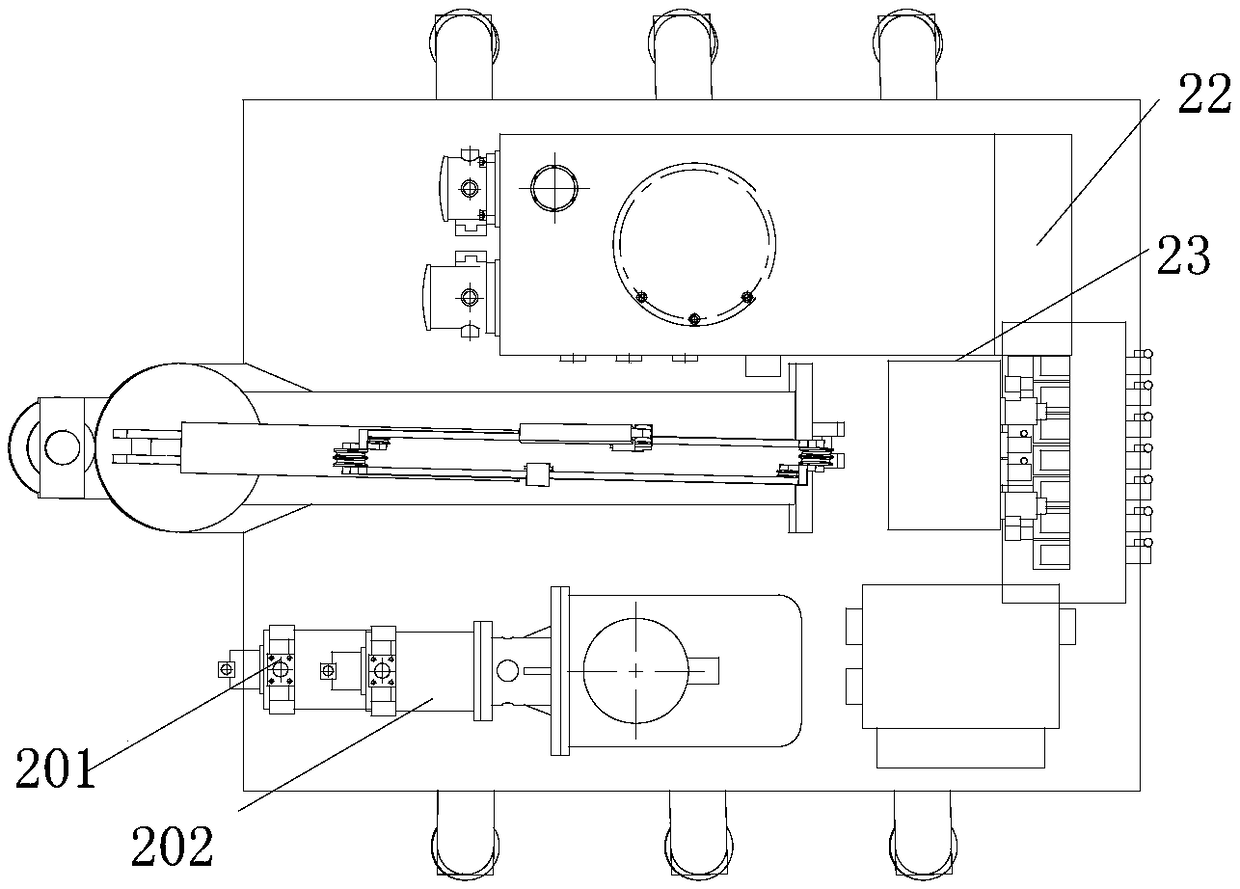

The application discloses a full automatic crystalline grain detection and sorting all-in-one machine. The all-in-one machine comprises nine main parts, i.e. a wafer workbench, a sorting workbench, a detection workbench, a transmission system, a wafer workbench pushing device, a sorting workbench pushing device, a detection workbench pushing device, a swing arm mechanism and a chip sorting storage. The all-in-one machine disclosed by the application ameliorates the traditional arrangement and the mechanical structure of the prior art, takes and places corresponding disk sheets via that the disk sheets freely pass in and out between the workbenches and the chip sorting storage via the transmission system and the pushing devices, and synchronously achieves the detection and the sorting of crystalline grains; and meanwhile, the transmission system is provided with two buffer area positions, can reduce the time of an exchange between disk sheets to be sorted and sorted disk sheets and another exchange between the disk sheets to be detected and detected disk sheets, and further accelerates the time and the efficiency of the sorting and the detection of the crystalline grains. The full automatic crystalline grain detection and sorting all-in-one machine has the characteristics of efficient disk sheet exchange, smart whole machine, impact structure, and good stability of the whole machine and expansion performance of the chip sorting storage.

Owner:广东志成华科光电设备有限公司

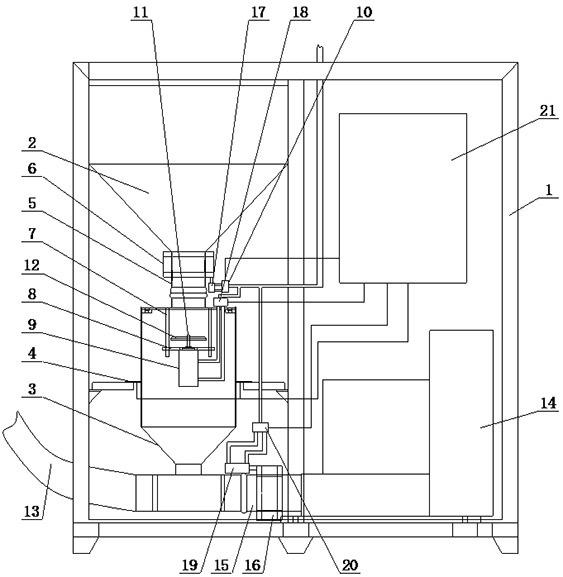

Detector for detecting visible foreign matter in bottled liquid medicine

ActiveCN103048334ALower installation heightThe whole machine is compactOptically investigating flaws/contaminationImage captureBiomedical engineering

The present invention relates to a detector for detecting visible foreign matter in bottled liquid medicines, comprising a base, and a bottle inlet device, a plate rotation device, a light source device, an image capturing device, a bottle clamping and releasing device, and a bottle outlet device fixed on the base. The bottle inlet device is used for advancing the to-be-detected liquid medicine bottles, the liquid medicine bottles are rotated by the plate rotation device to facilitate the image capturing device to detect, the light source device provides light for the liquid medicine bottles, the bottle clamping and releasing device is used for clamping and releasing the liquid medicine bottles, and the detected liquid medicine bottles are removed from the bottle outlet device. The detector is reasonable in structure design, can automatically detect liquid medicine bottles through streamlined operations, does not need artificial detection of foreign matters, prevents subjective errors on artificial detection, and improves work efficiency.

Owner:东营益盟盛药业有限公司

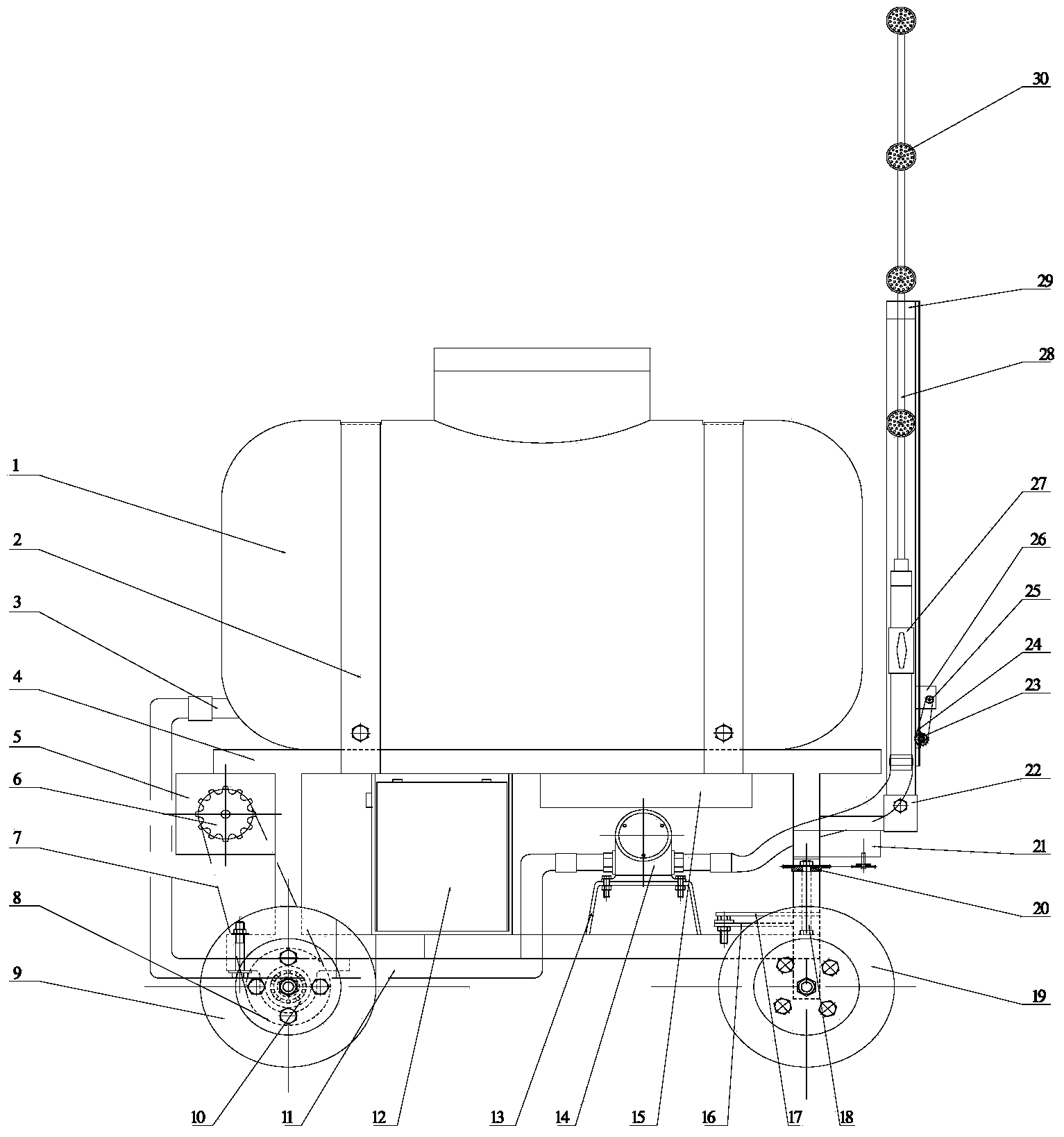

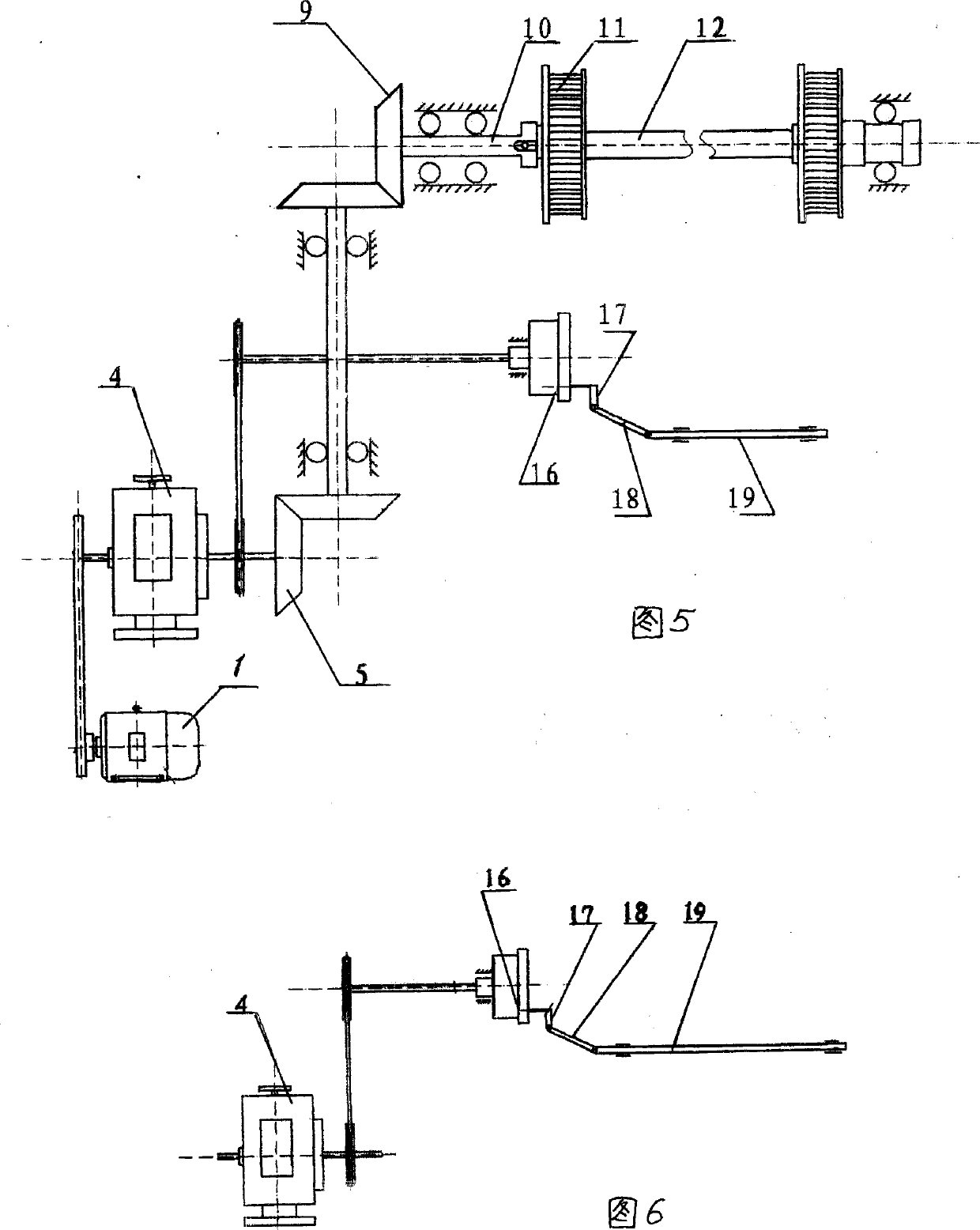

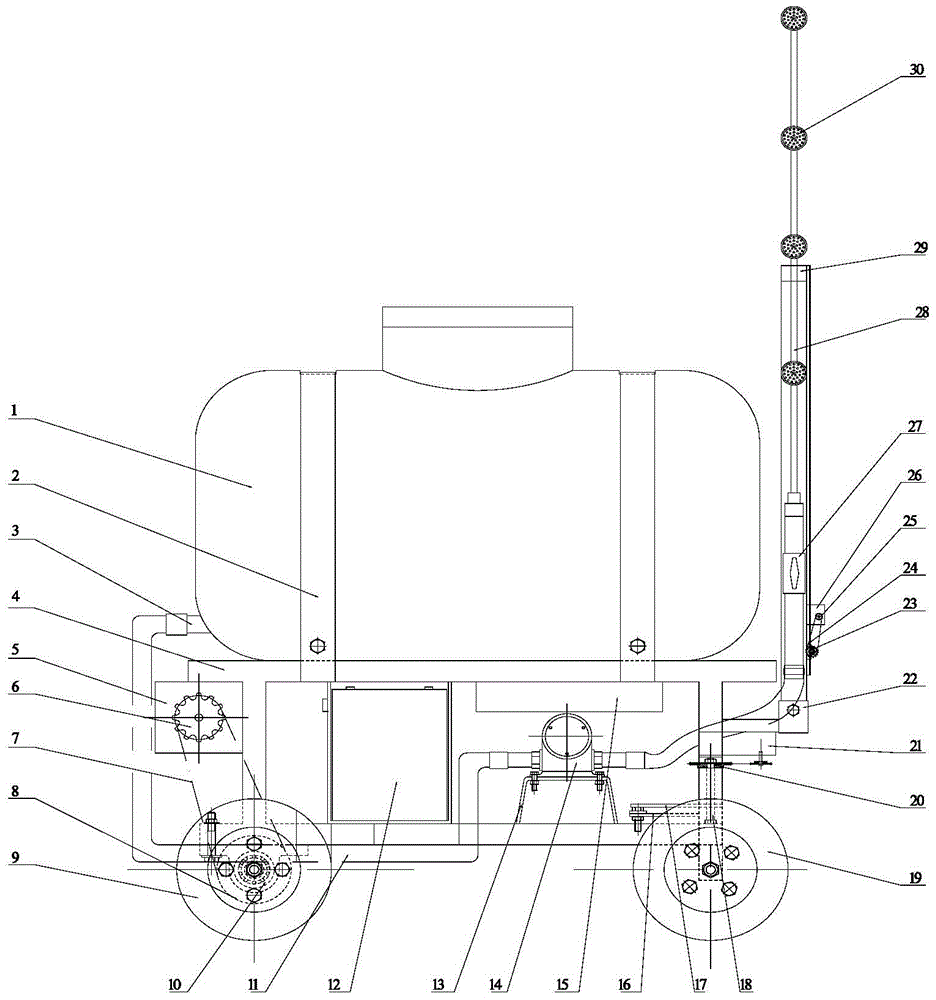

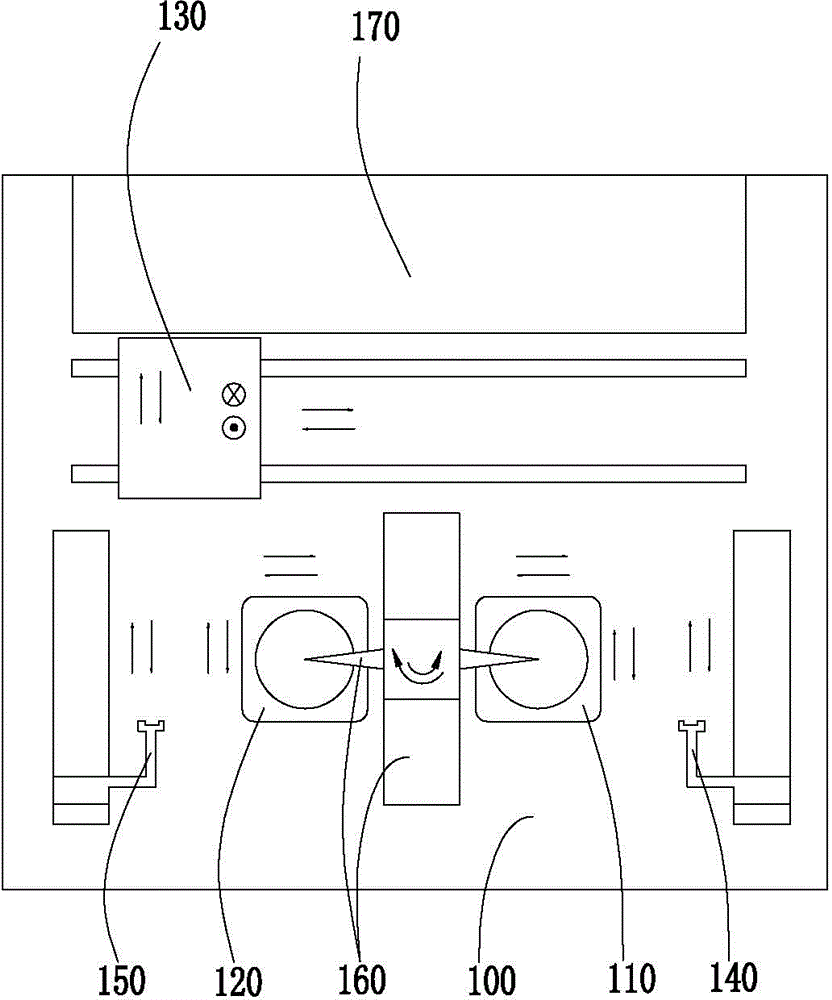

Electric remote-control electrostatic adjustable profile modeling spray method

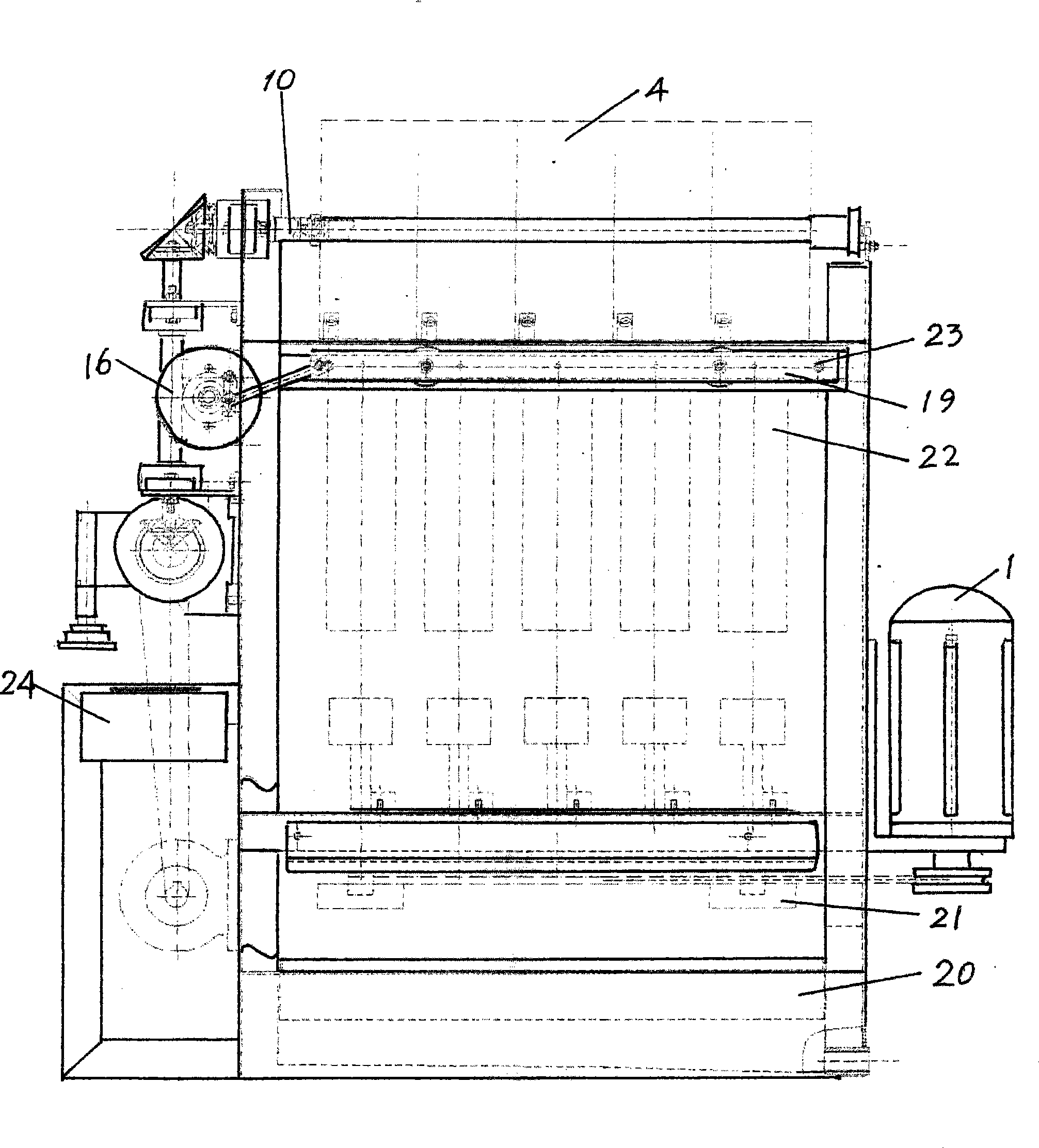

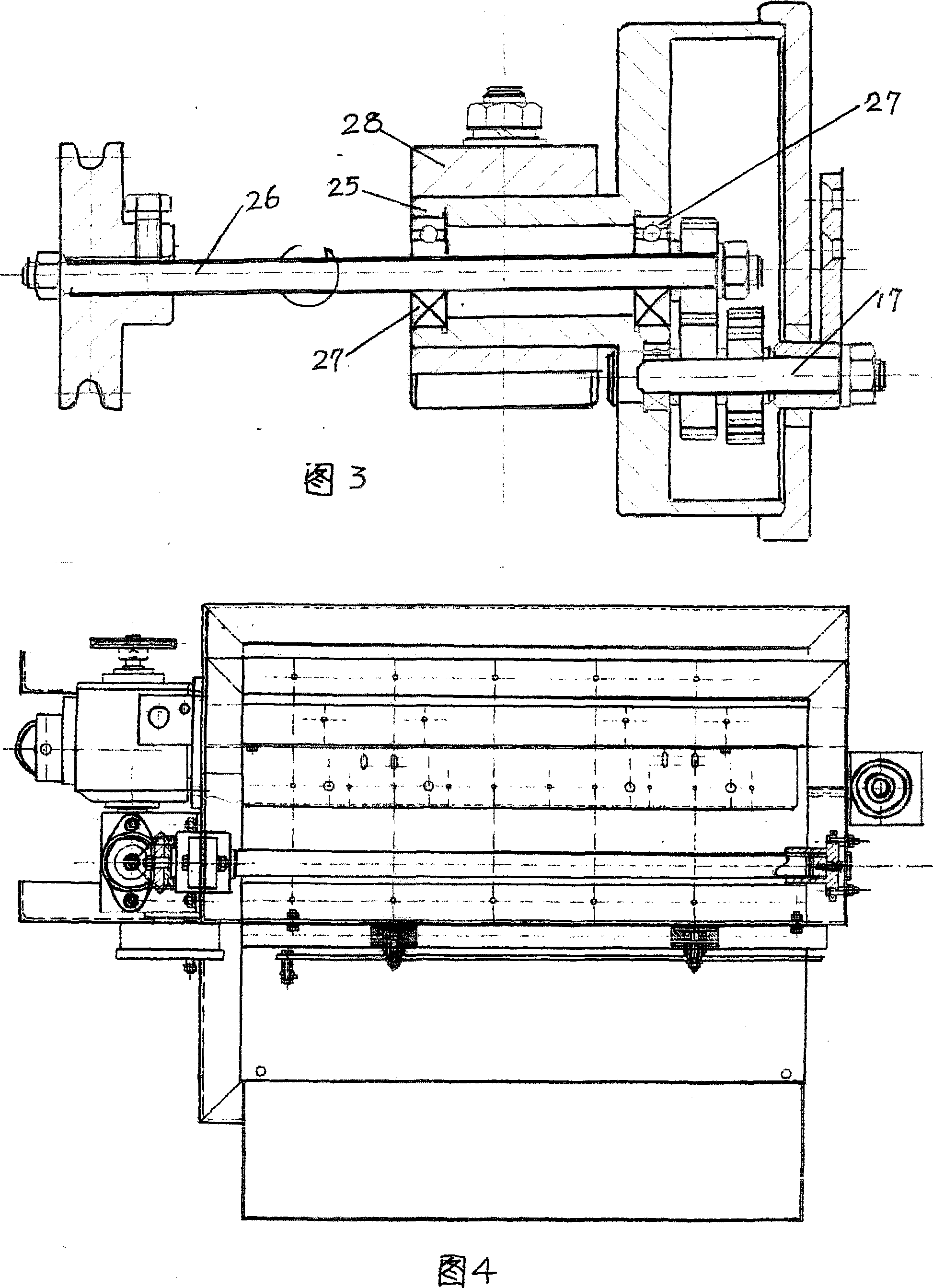

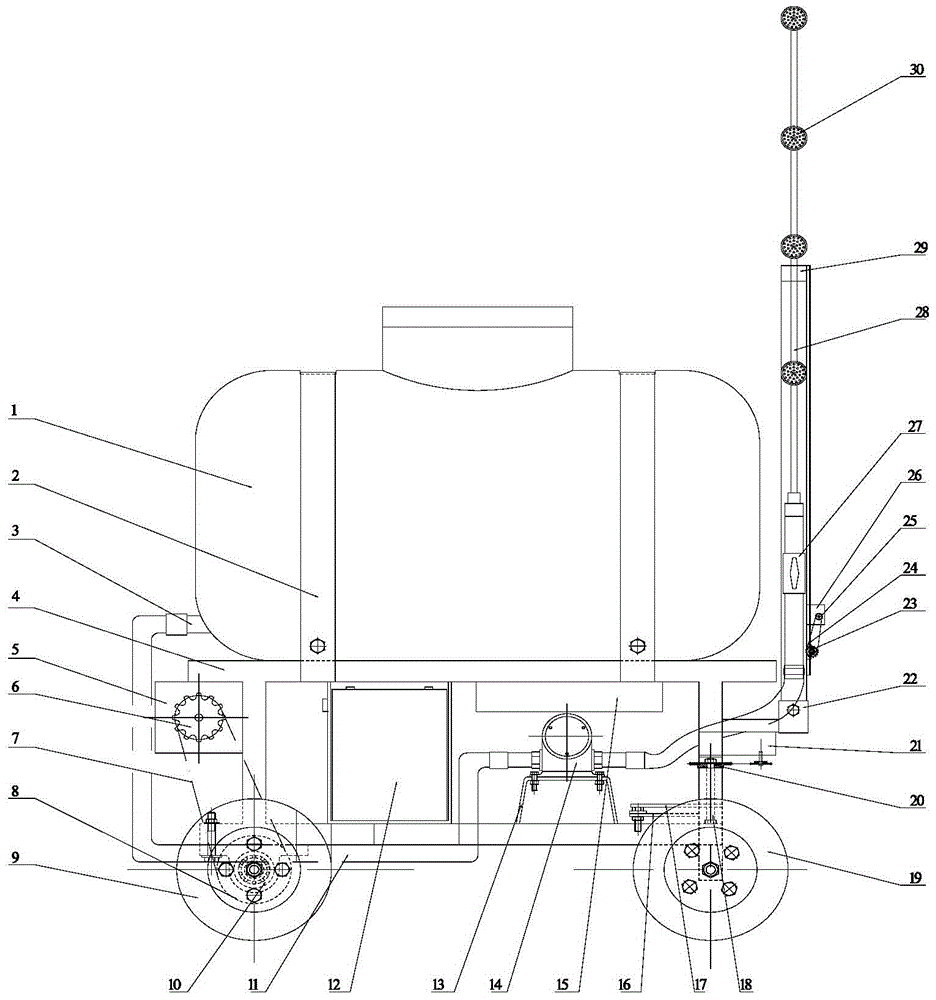

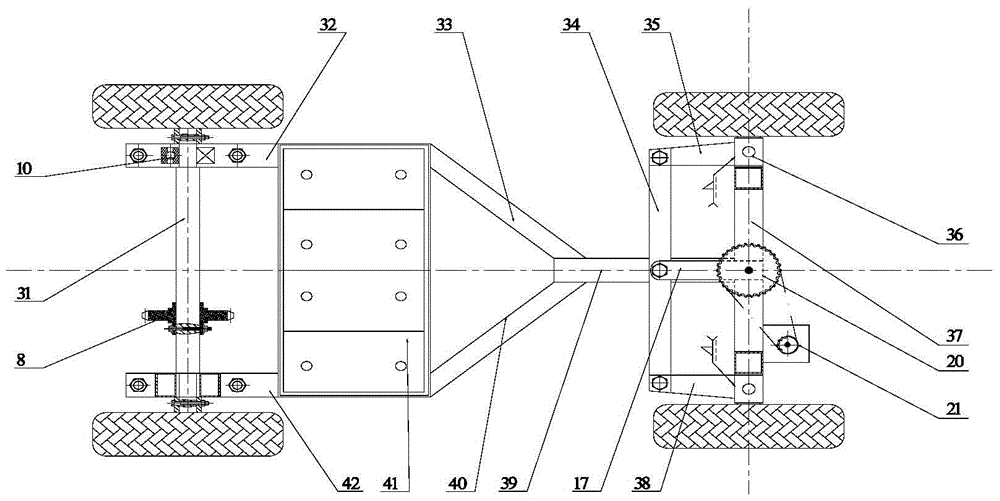

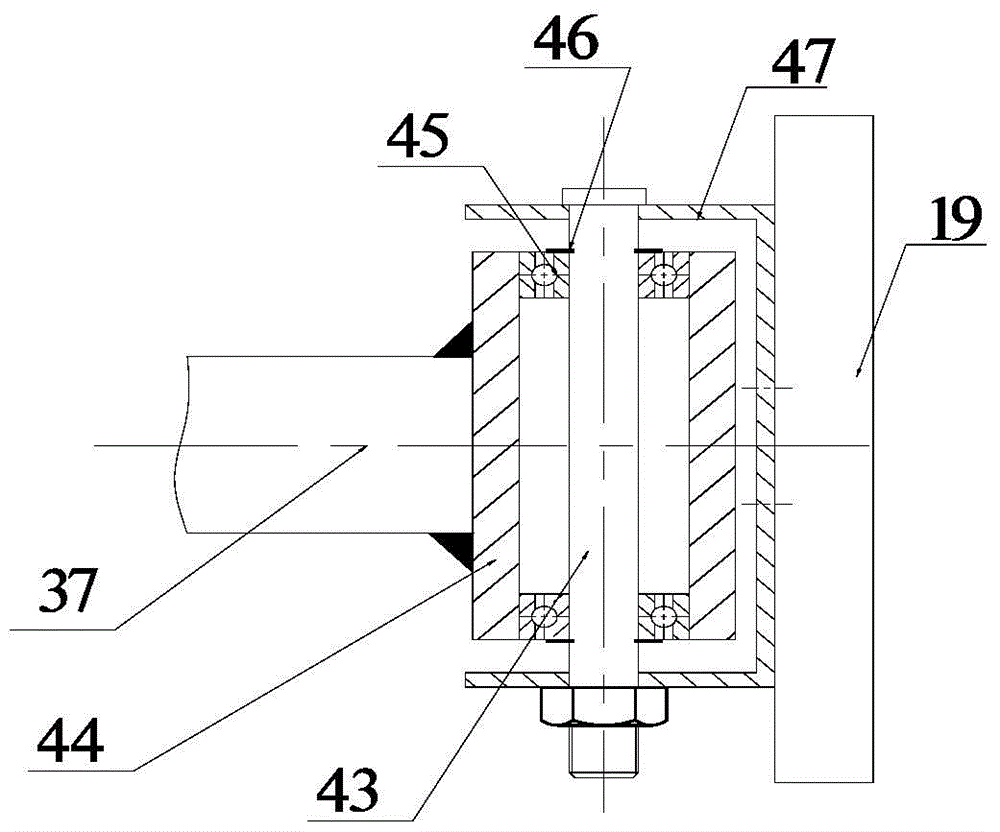

ActiveCN104351156AReduce labor intensityImprove productivityPressurised distribution of liquid fertiliserInsect catchers and killersDrive wheelSprayer

The invention discloses an electric remote-control electrostatic adjustable profile modeling spray method which is to implement spray operation by an electric remote-control electrostatic adjustable profile modeling sprayer. The sprayer comprises a frame as well as a power system, a steering system and a spraying system on the frame, wherein two driving wheels in the power system serve as rear wheels; two steering wheels in the steering system serve as front wheels; the spraying system comprises a water tank (1), a three-way valve (3), a water pipe (11), a water pump (14), a spray lance (28), a sprayer (30) and a spray lance control apparatus; a four-side active rocker mechanism is composed of a left supporting rod mechanism, a right supporting rod mechanism, an upper guide block and a lower guide block; the steering system comprises a steering motor (21), a steering chain wheel (20), a guide plate (17), steering wheels (19), a steering wheel connecting mechanism (36) and a steering mechanism. The electric remote-control electrostatic adjustable profile modeling spray method is easy to implement, capable of being applied to various environments and high in spraying efficiency.

Owner:HUNAN AGRICULTURAL UNIV

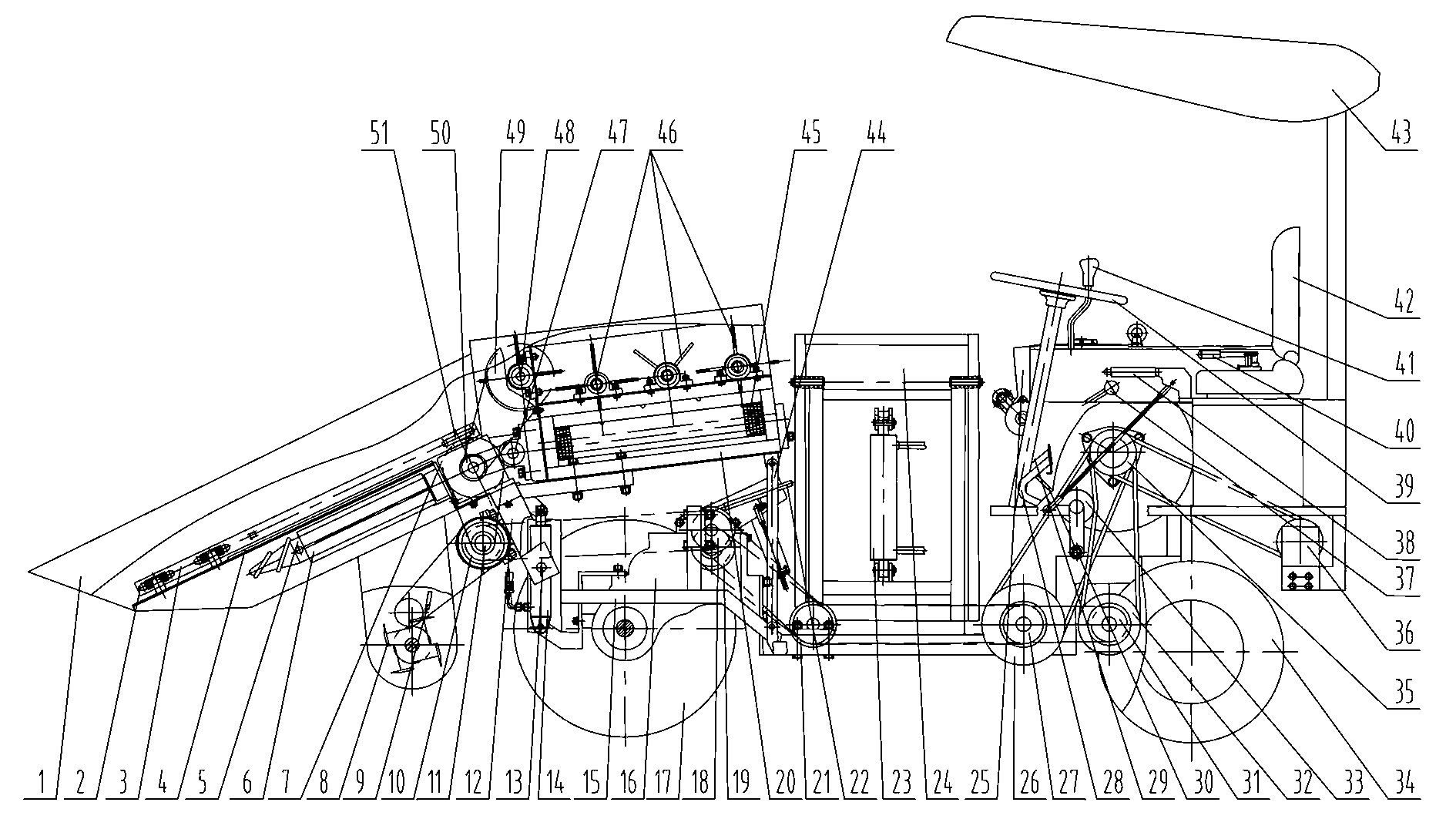

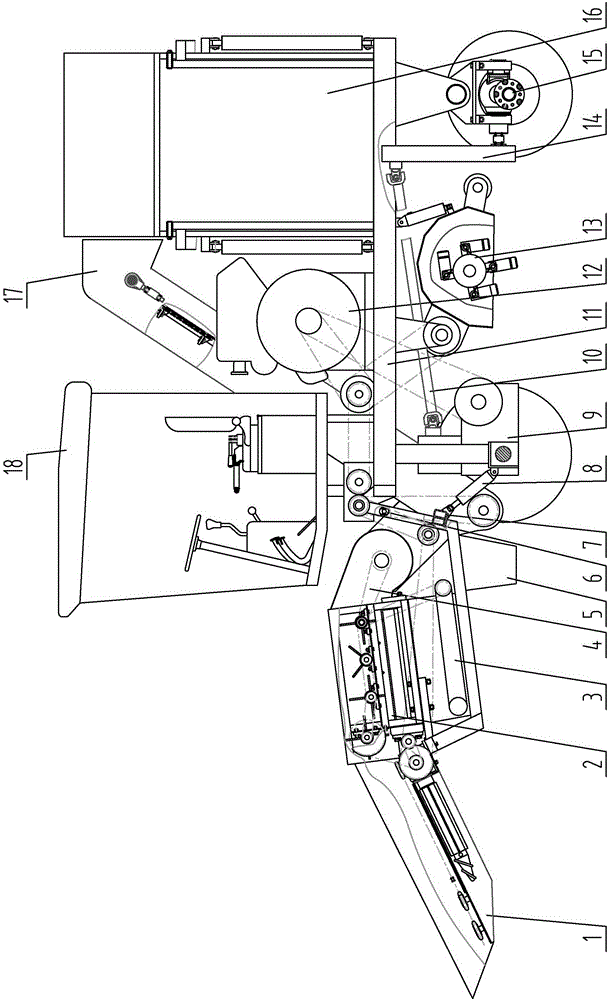

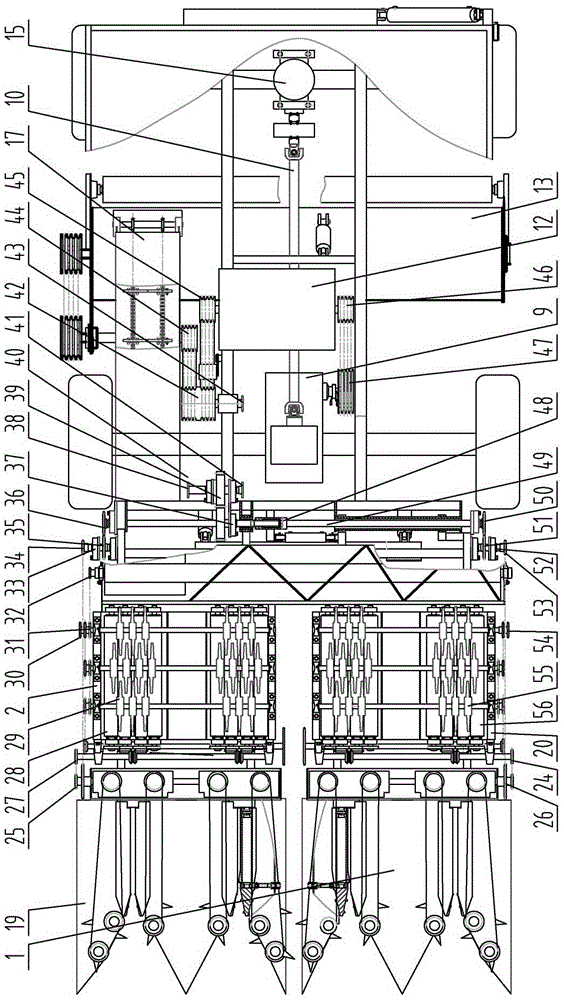

Double-row maize harvesting machine for turning and discharging maize on hydraulic side of grain tank

The invention aims to provide a double-row maize harvesting machine for turning and discharging maize on a hydraulic side of a grain tank. The machine has the structural characteristics that a cluster tank is installed in the middle of the whole machine and installed on a rack through a turn oil cylinder; a diesel engine is installed on the right side of the rack behind the cluster tank; a driver seat is installed on the rack on the left rear part of the whole machine; a rear axle guide wheel assembly is installed below the rack; a canopy is arranged above the driver seat; a travelling transmission gear is arranged in front of the cluster tank; drive wheels are installed on drive shafts on the two ends of the travelling transmission gear; a peeling rack is arranged above the travelling transmission gear; the front part of the peeling rack is fixedly connected with a cutting platform rack, installed in a straight groove on the front part of the rack through sliding blocks which are installed on fixed shafts on the two sides of the lower part of the cutting platform rack and installed on the rack through a cutting platform lift oil cylinder; the rear part of the peeling rack is assembled on the rack through a connecting rod; a cutting platform transmission case is installed on the rear part of the cutting platform rack; a stem pulling roller is installed on the front output end of the cutting platform transmission case; and a spike picking plate and a conveying chain are arranged above the stem pulling roller, and a hobbing cutter and a stationary cutter are installed below the stem pulling roller. By adopting the structure, the whole machine is small, light in weight and low in gravity center, and the use reliability, adaptability and working efficiency of the machine are increased.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

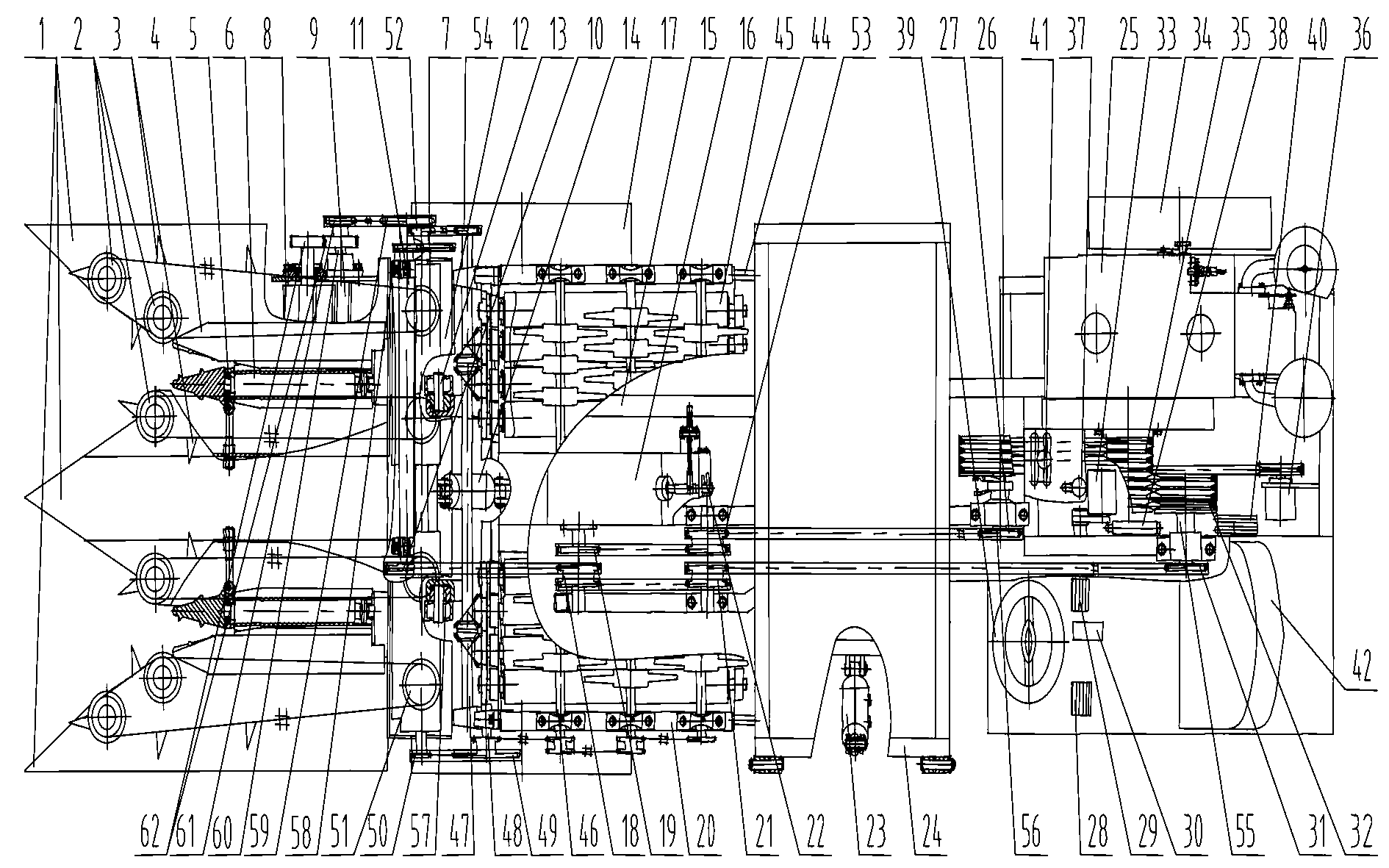

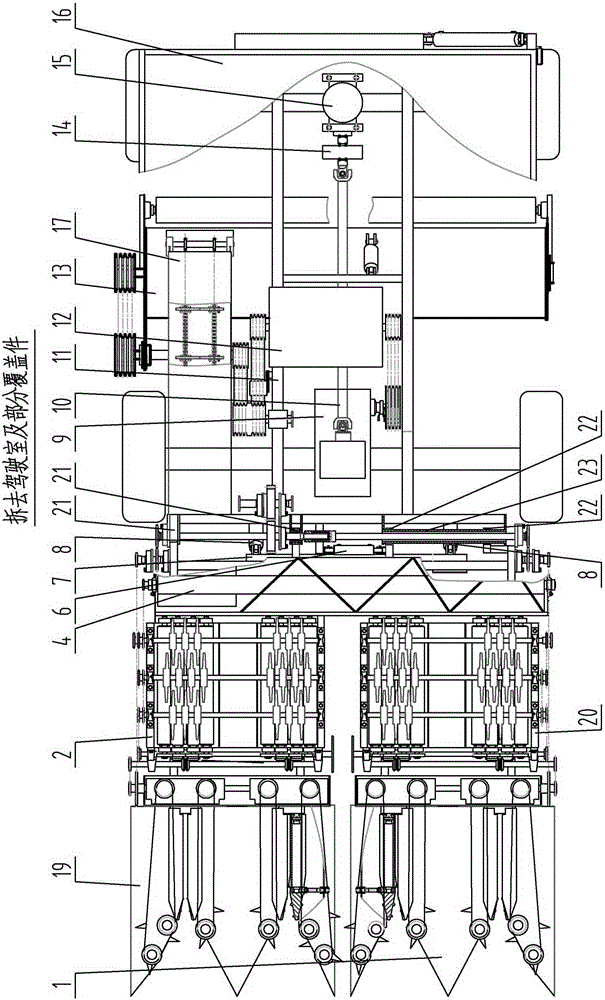

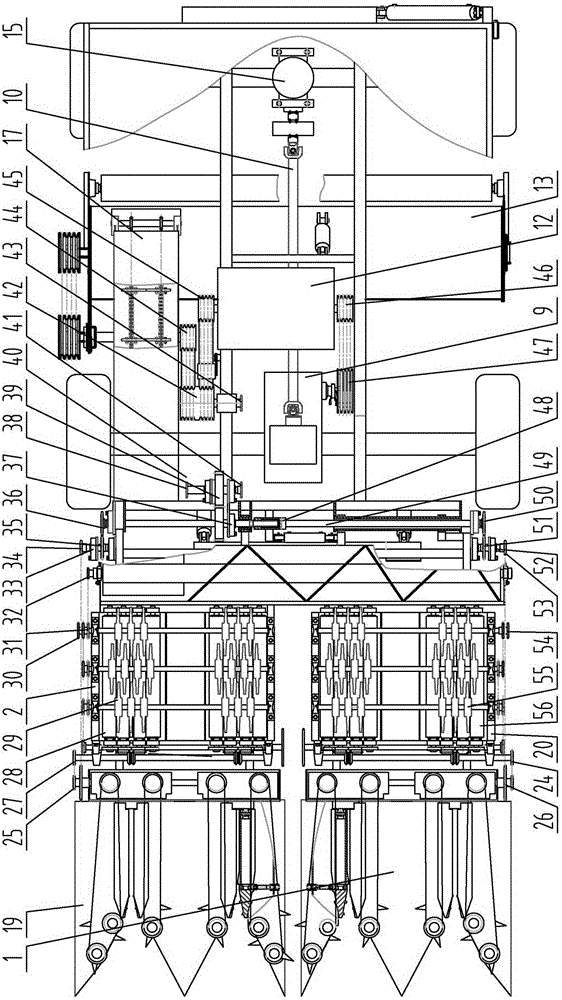

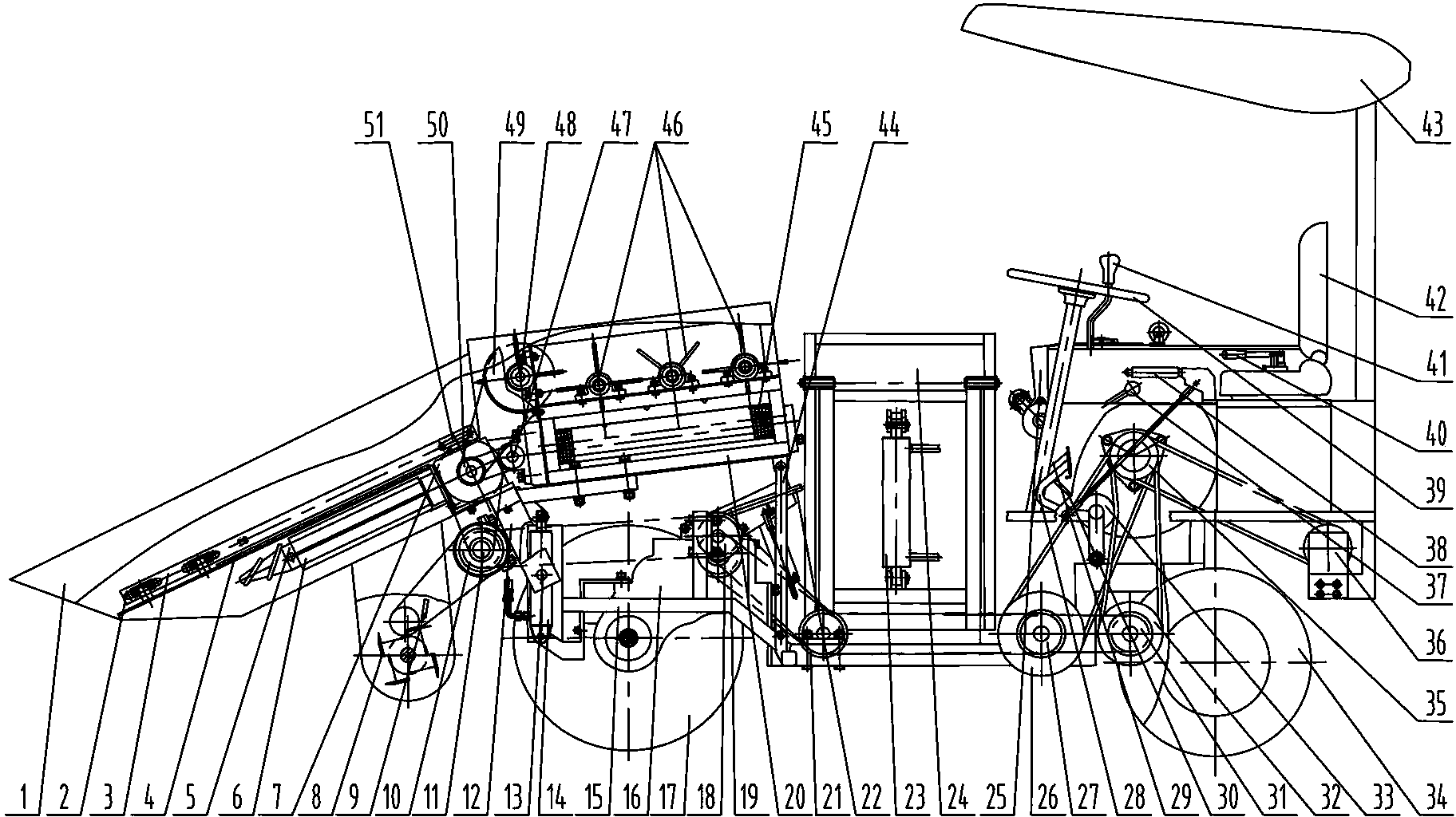

Four-wheel-driven three-row corn harvester with front husking machine

A four-wheel-driven three-row corn harvester with a front husking machine mainly comprises a header, a straw cut-off device, a frame, a husking device, a screw conveyor, a diesel engine, a travelling device, a straw recycling machine, a driving cab, a control mechanism, an elevator, a grain storage box and the like. The four-wheel-driven three-row corn harvester with the front husking machine is characterized in that the diesel engine is mounted in the middle of the frame; the rear end of the header is connected with the front end of the husking device, and the header and the husking device are disposed in front of the frame together; the straw cut-off device is disposed in the lower rear of the header; the elevator is disposed on the right of the engine machine, the front of the elevator is connected with the screw conveyor, and the rear of the elevator is connected with the grain storage box; the screw conveyor is disposed in the front of the diesel engine, the front of the screw conveyor is connected with the husking device, and the rear of the screw conveyor is overlapped with the elevator; the driving cab is disposed on the upper portion of the diesel engine and connected with the frame; the control mechanism is mounted inside the driving cab; the straw recycling machine is disposed in the lower rear of the frame; and the grain storage box is disposed in the upper rear of the frame. Due to the structure, the corn harvester is optimized in design, integrally compact, lightweight, low in center of gravity, high in gradeability, flexible and easy to operate. By the aid of unique integral structure configuration, the four-wheel-driven three-row corn harvester can be suitable for harvest in planes as well as in hilly areas, is higher in use reliability and adaptability and broad in market prospect.

Owner:SHANDONG CHANGLIN AGRI SCI EQUIP

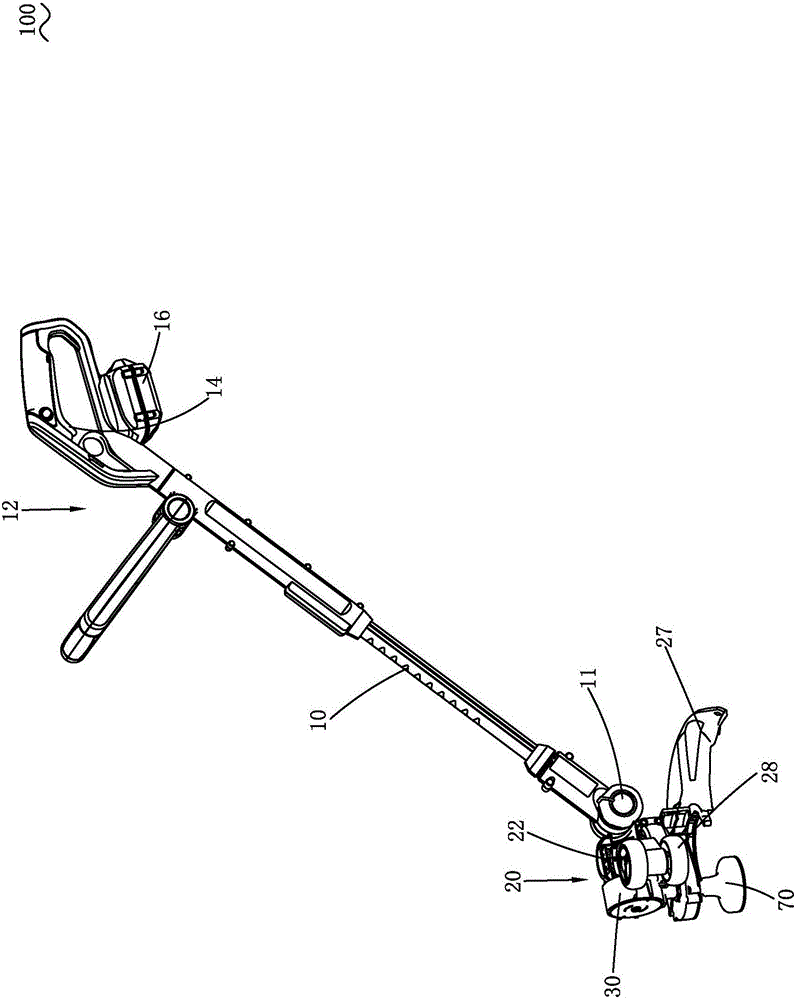

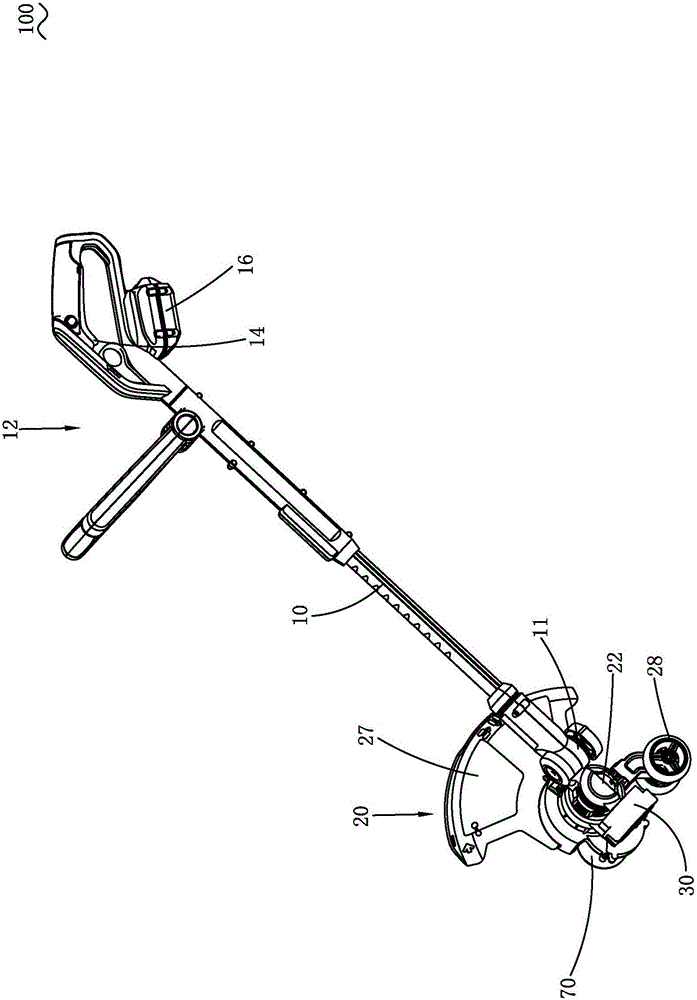

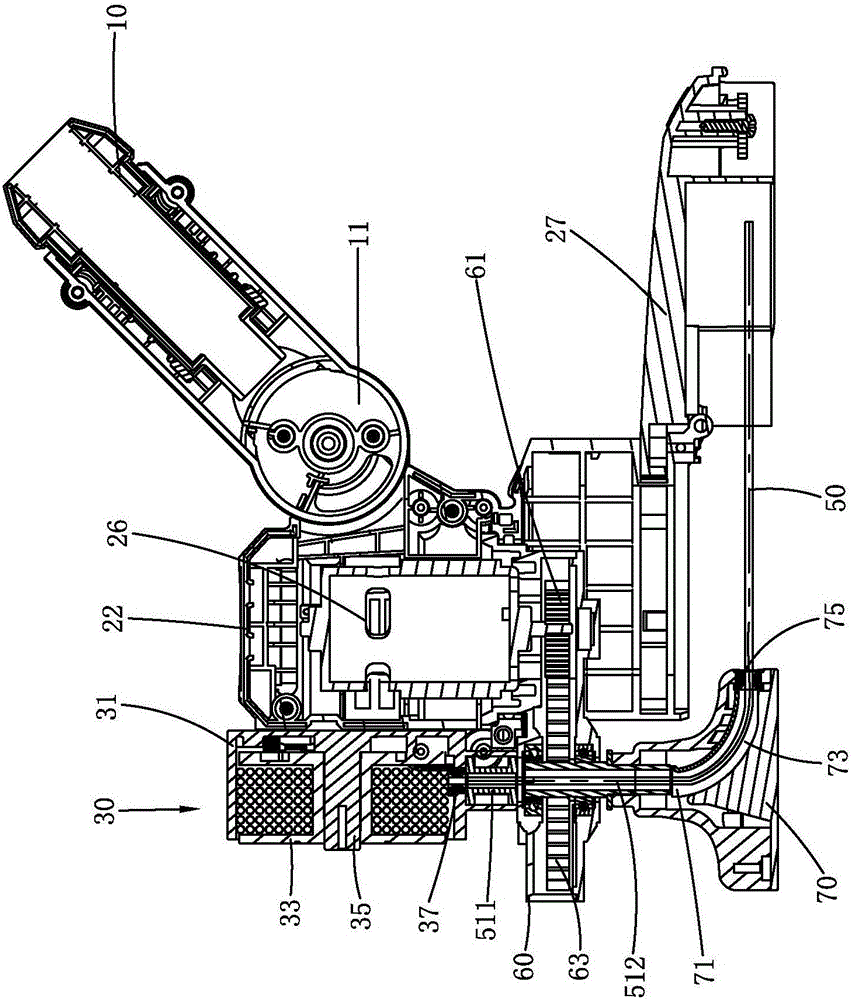

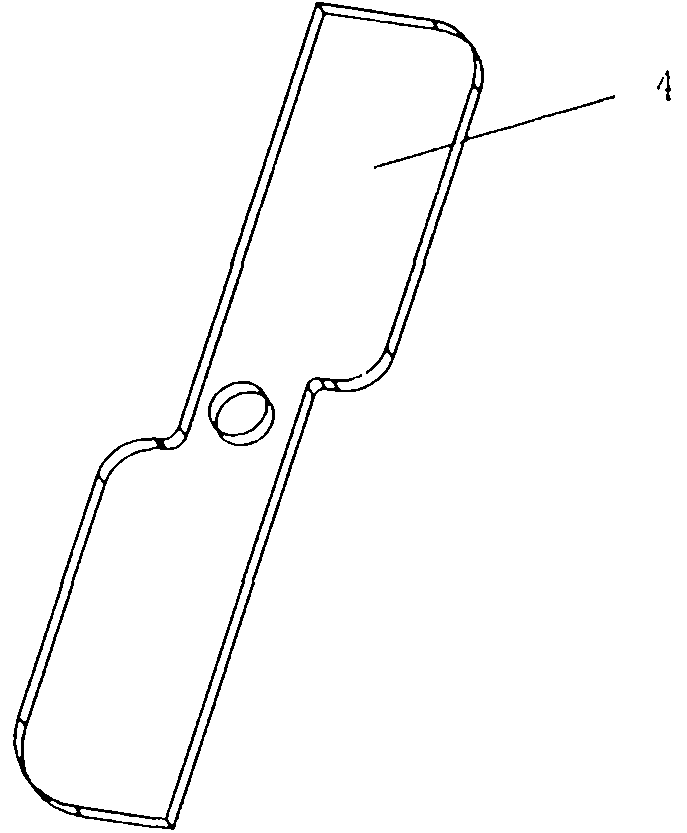

Grass trimmer

The invention discloses a grass trimmer. The grass trimmer comprises an extension rod, a handle assembly, a machine head, a grass trimming head, a motor and a wire coil assembly containing a grass trimming wire; the wire coil assembly is arranged on the machine head, located outside the grass trimming head and comprises a wire coil and a wire coil base, the wire coil is used for allowing the grass trimming wire to be coiled and is rotatably supported on the wire coil base, the wire coil has a first rotational state and a second irrotational state, centrifugal force generated by rotation of the grass trimming wire drives the wire coil in the first state to rotate to the second state, and the wire coil rotates from the first state to the second state to release the wire outwards. By arranging the wire coil outside the grass trimming head and releasing the wire through the centrifugal force generated by rotation of the grass trimming wire, the grass trimmer achieves the advantages that the wire coil replacement frequency is low, and wire releasing is convenient simultaneously.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

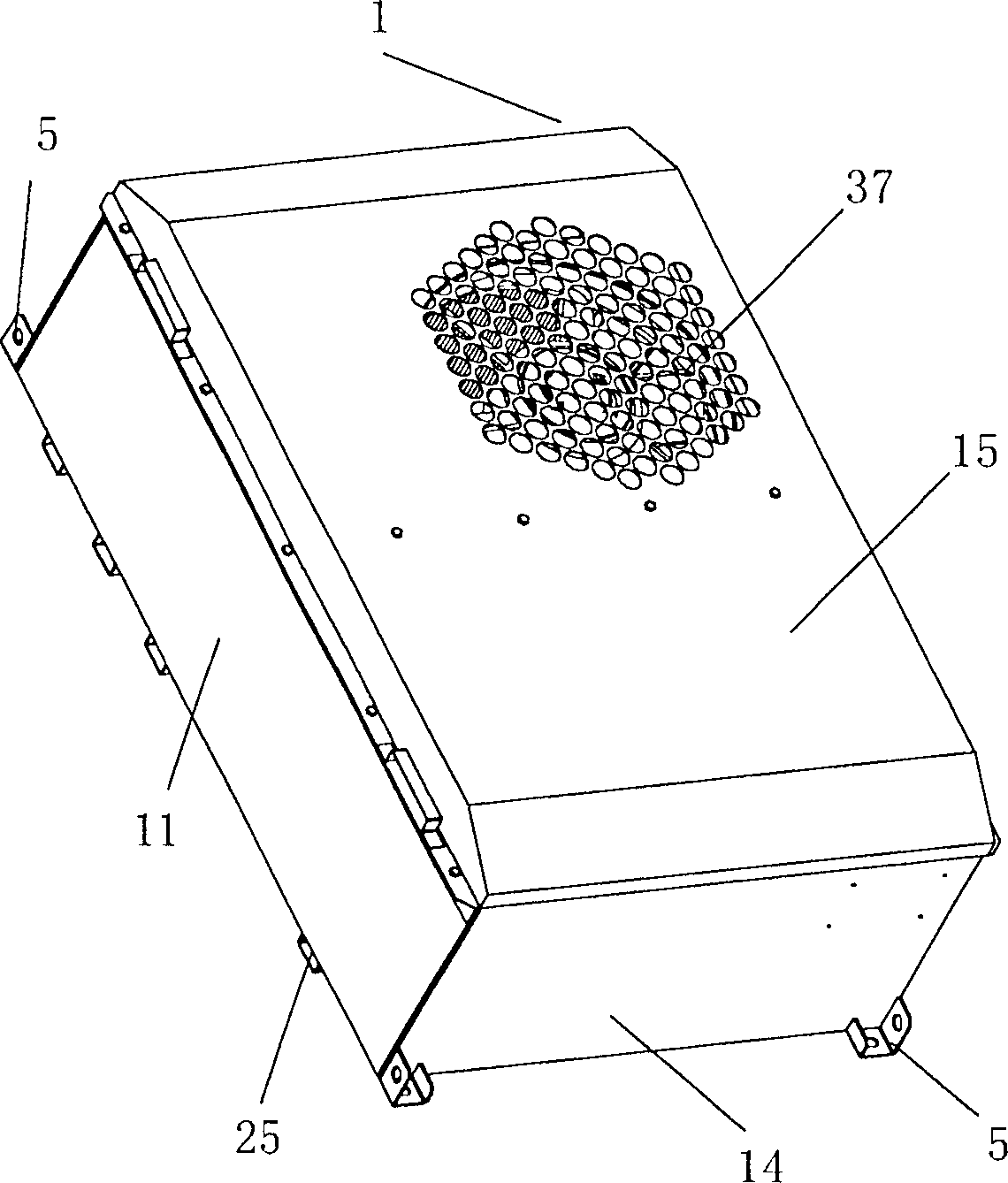

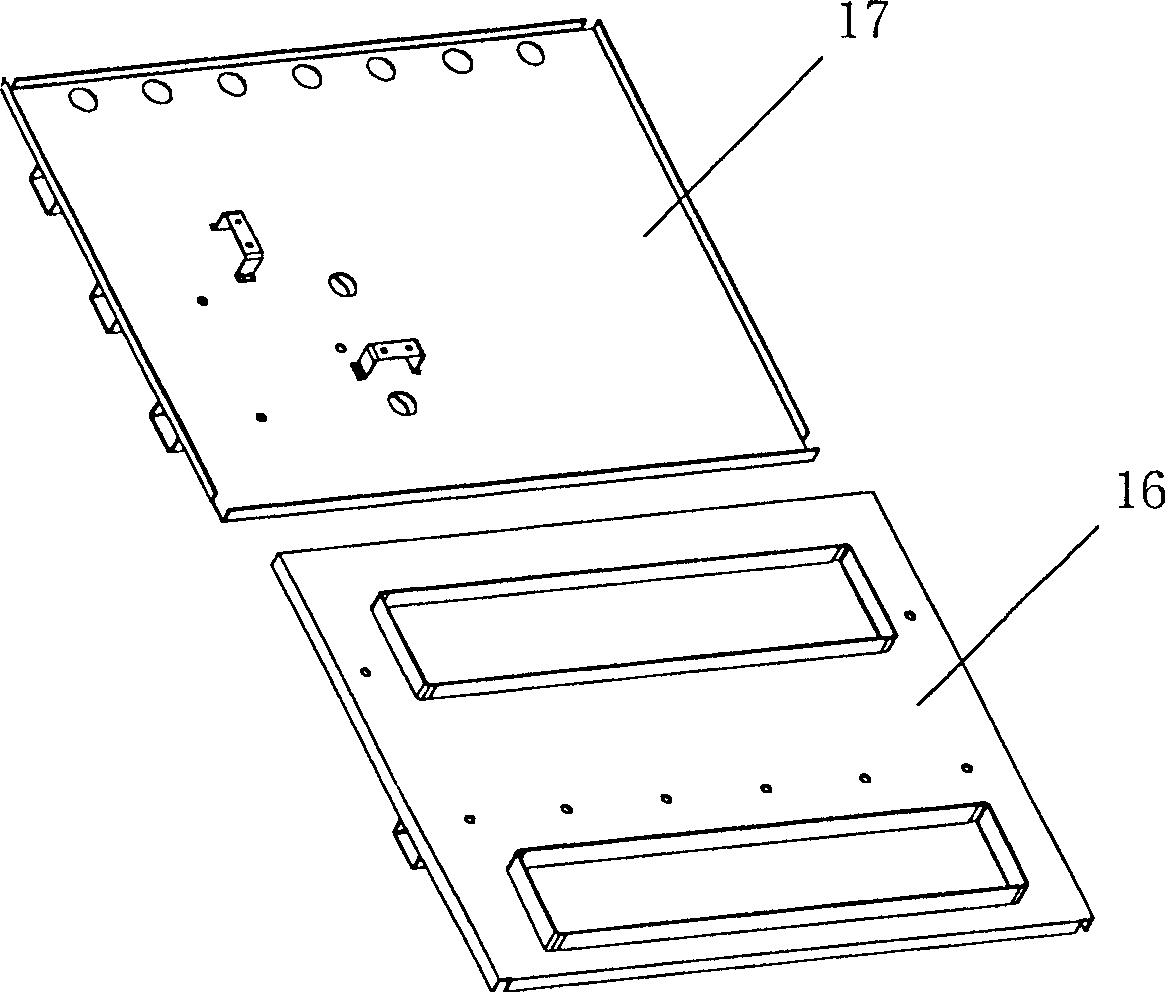

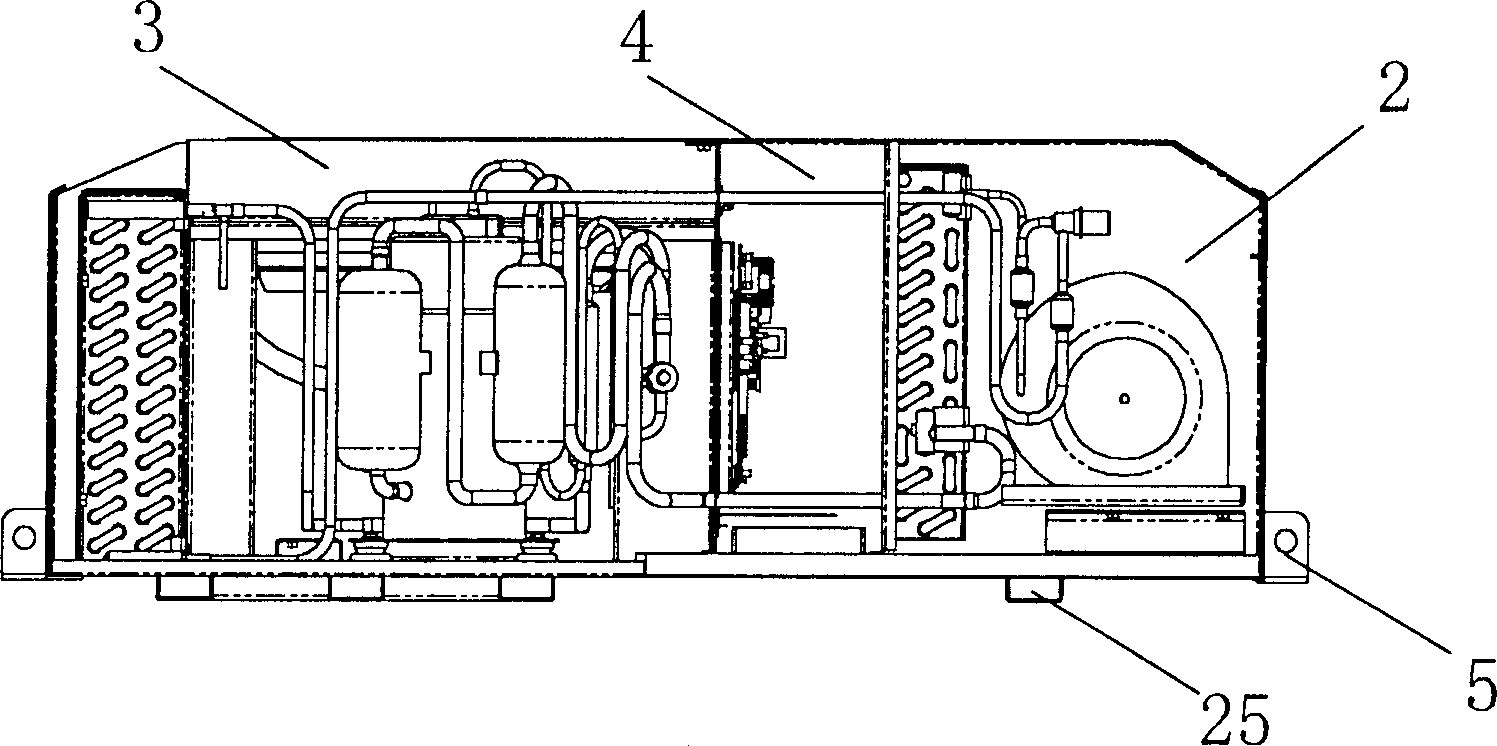

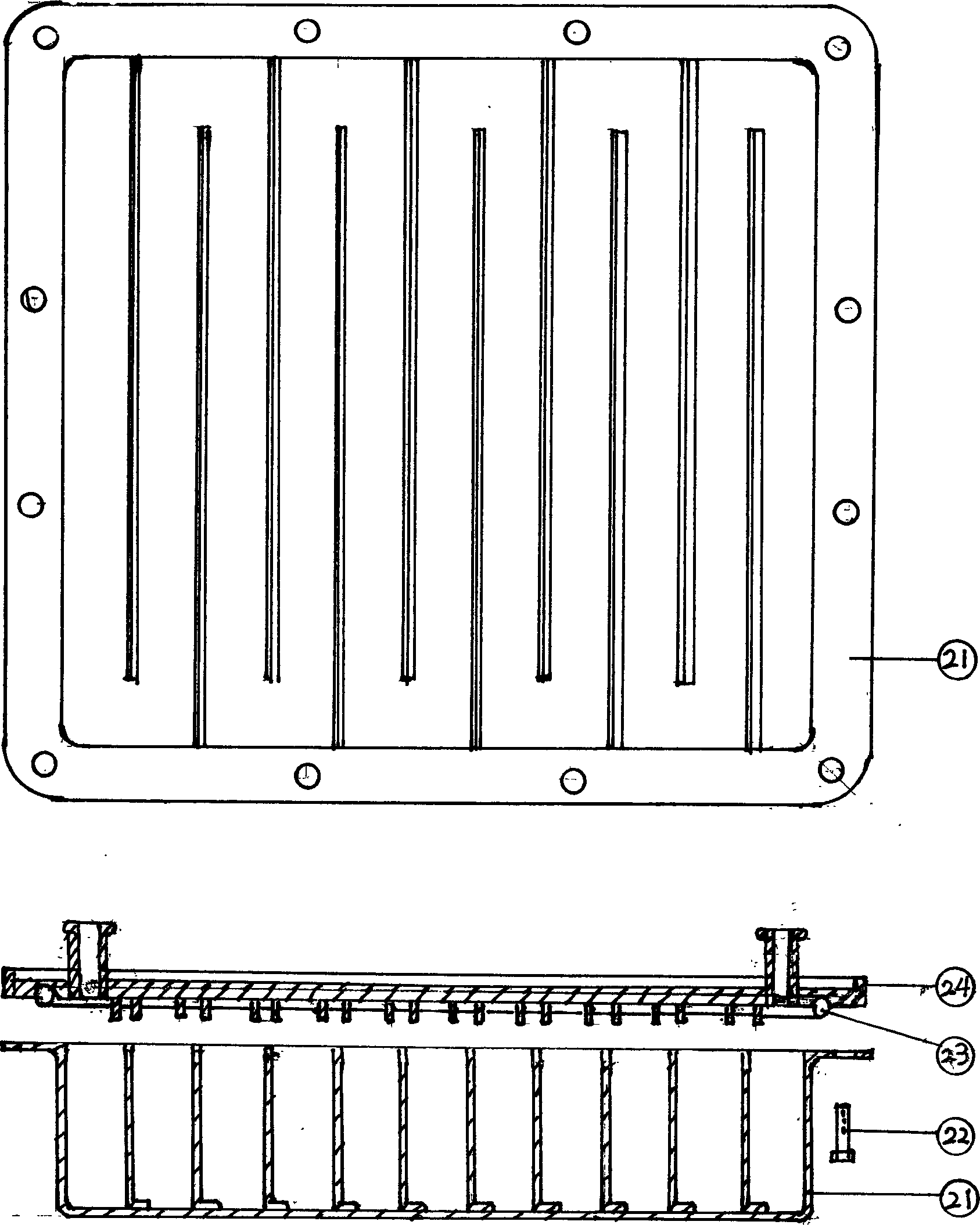

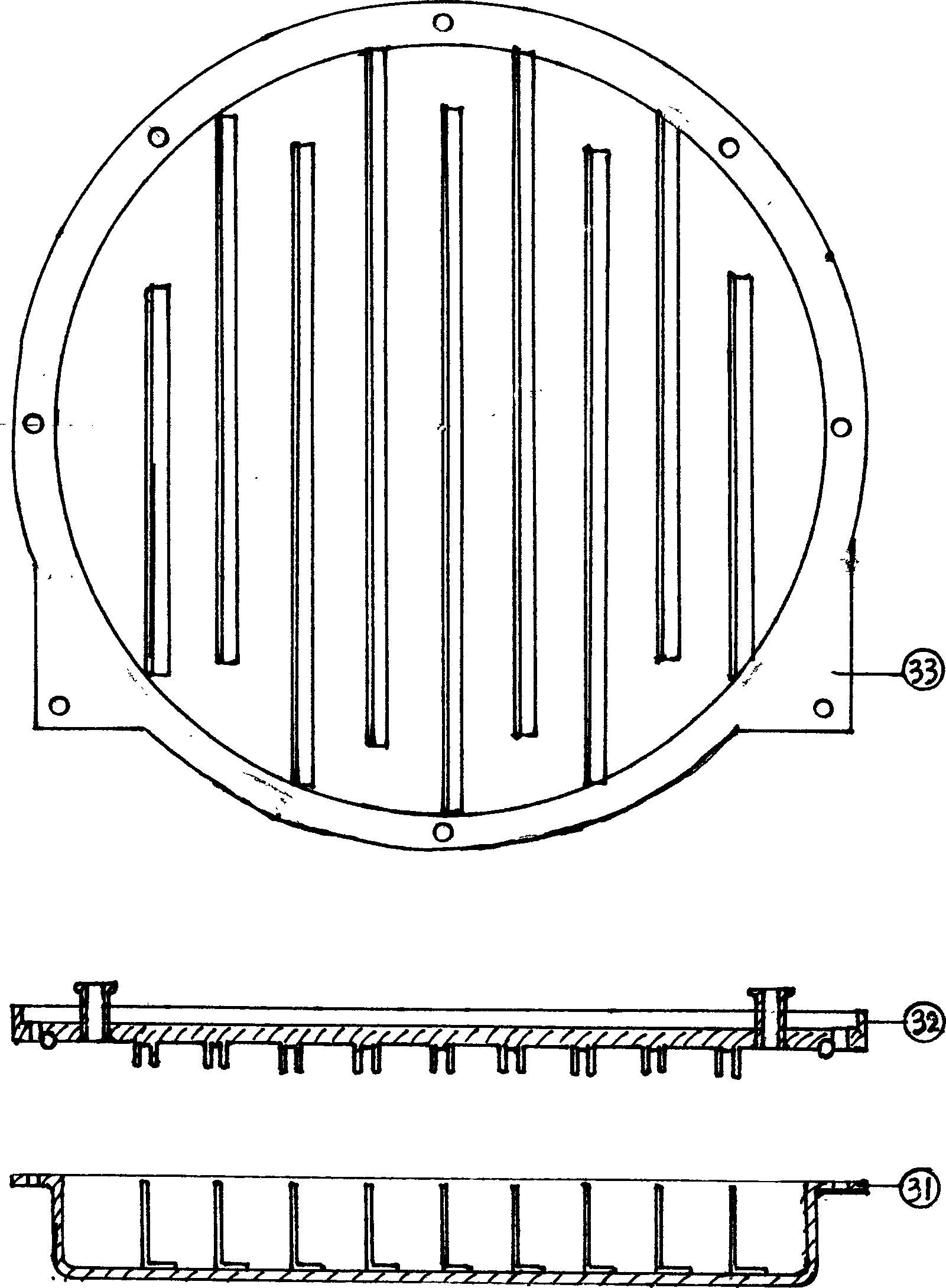

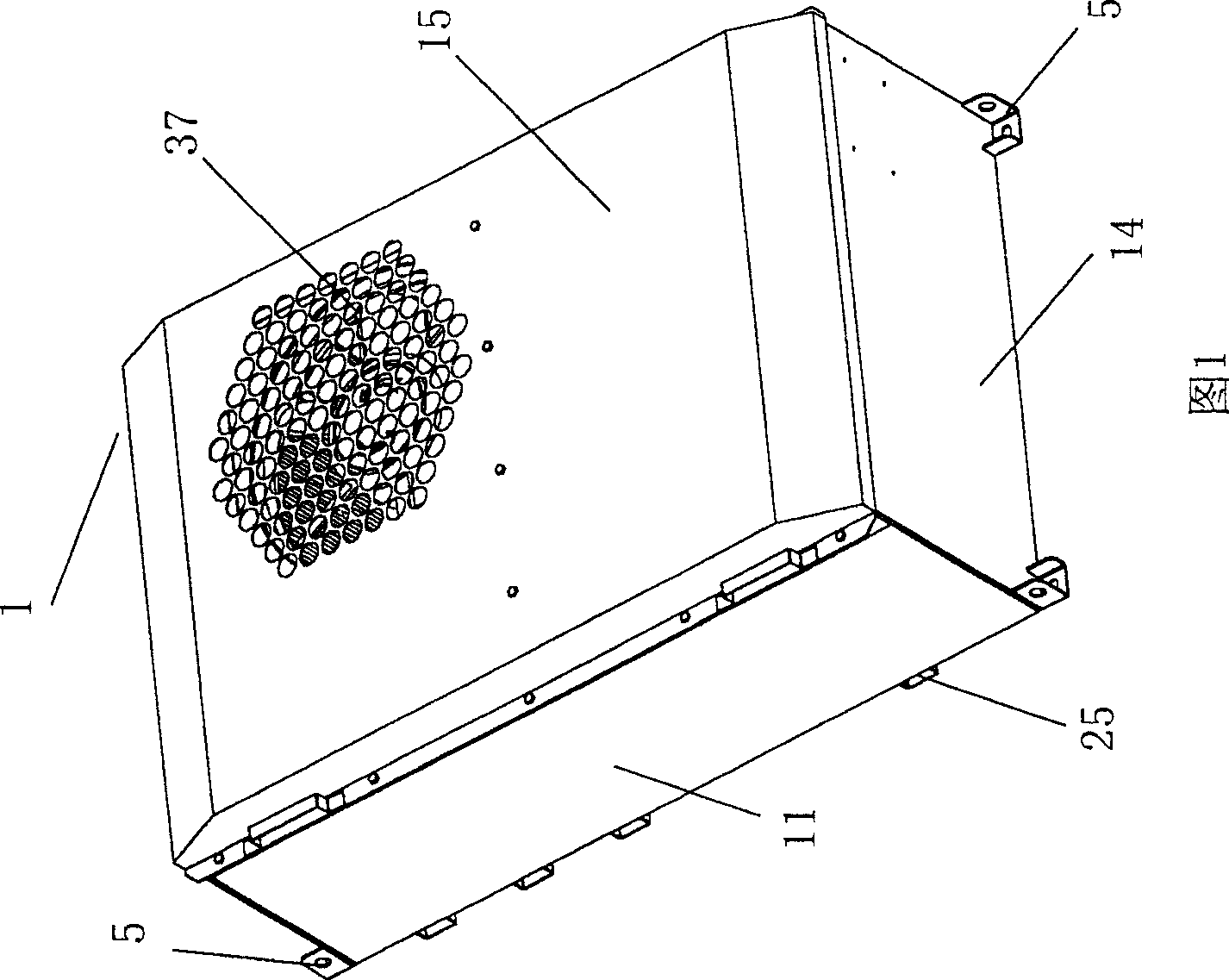

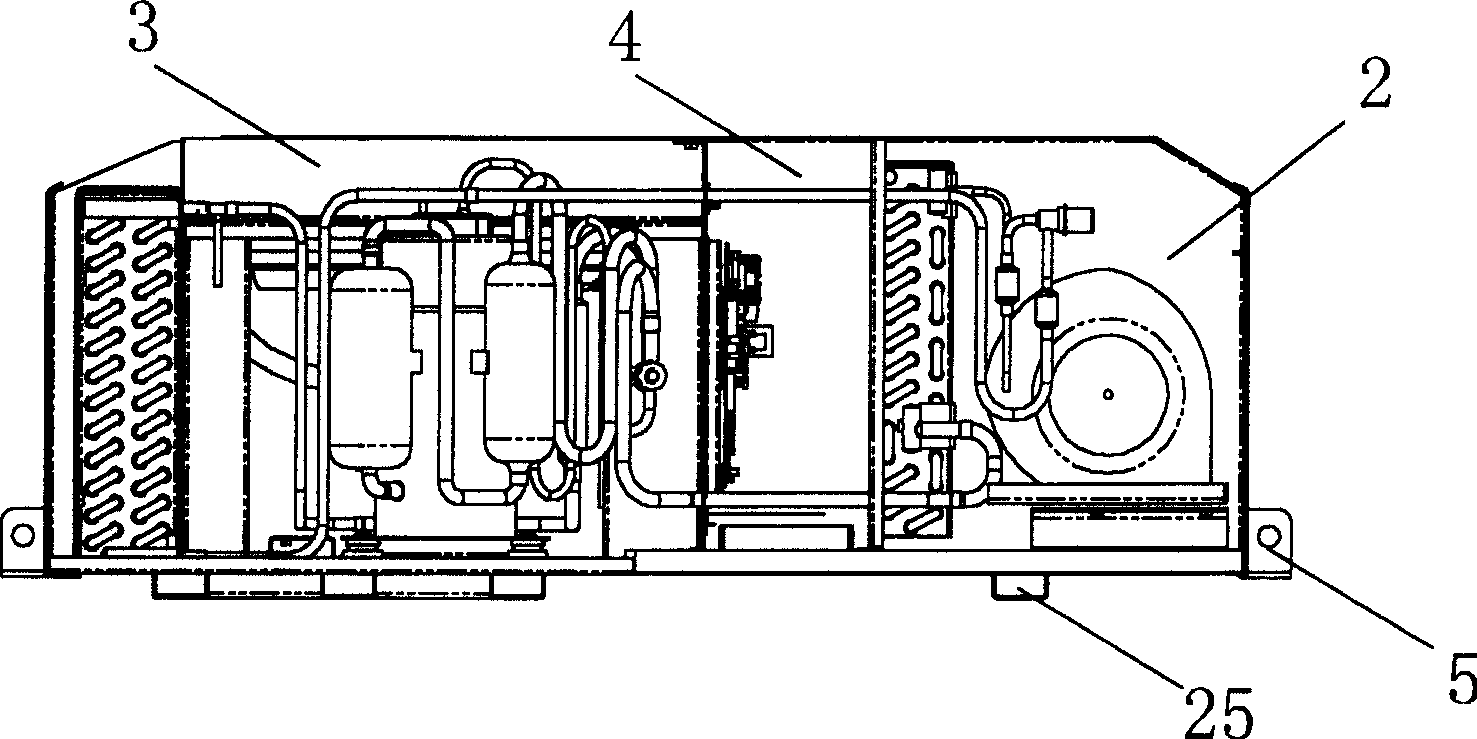

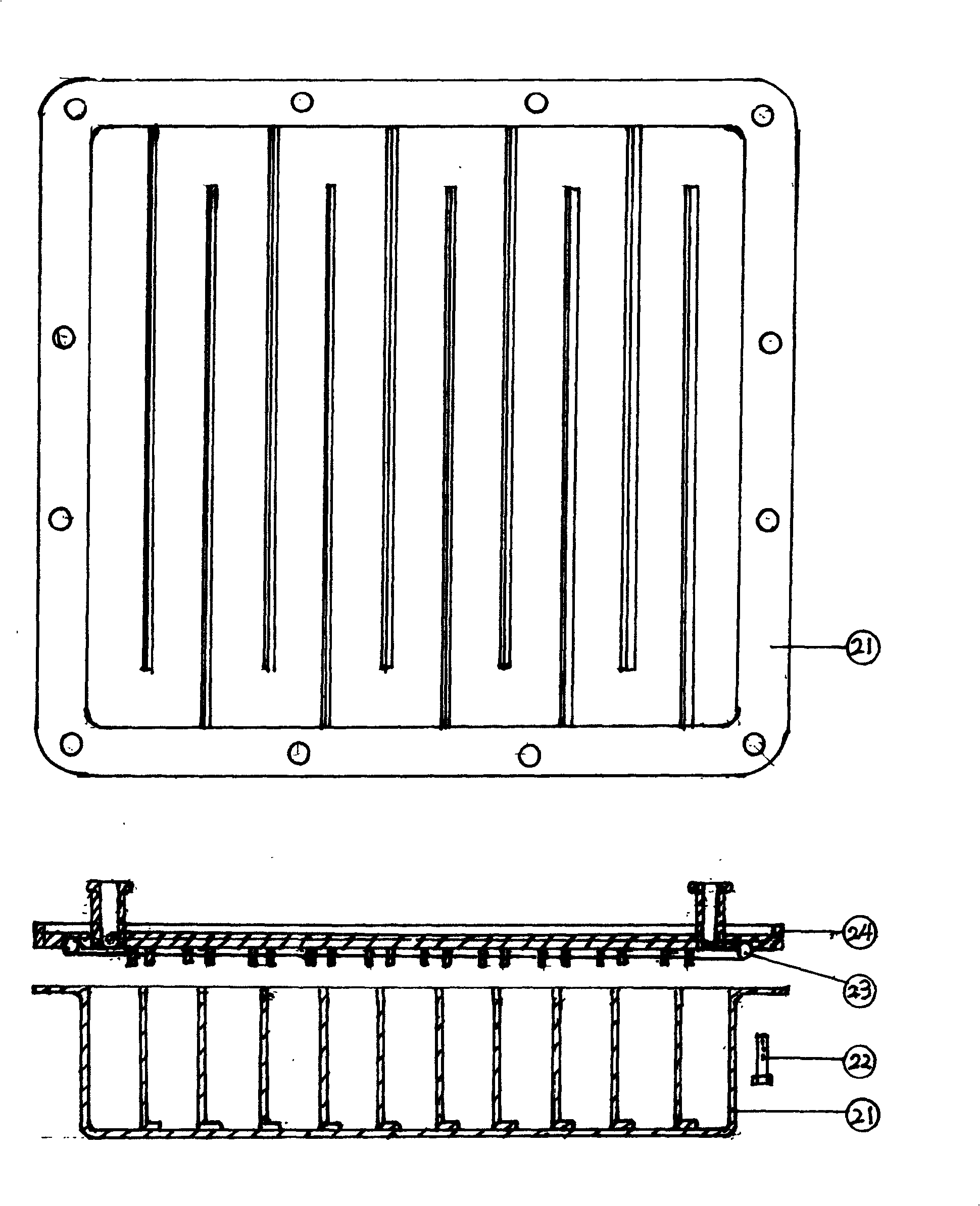

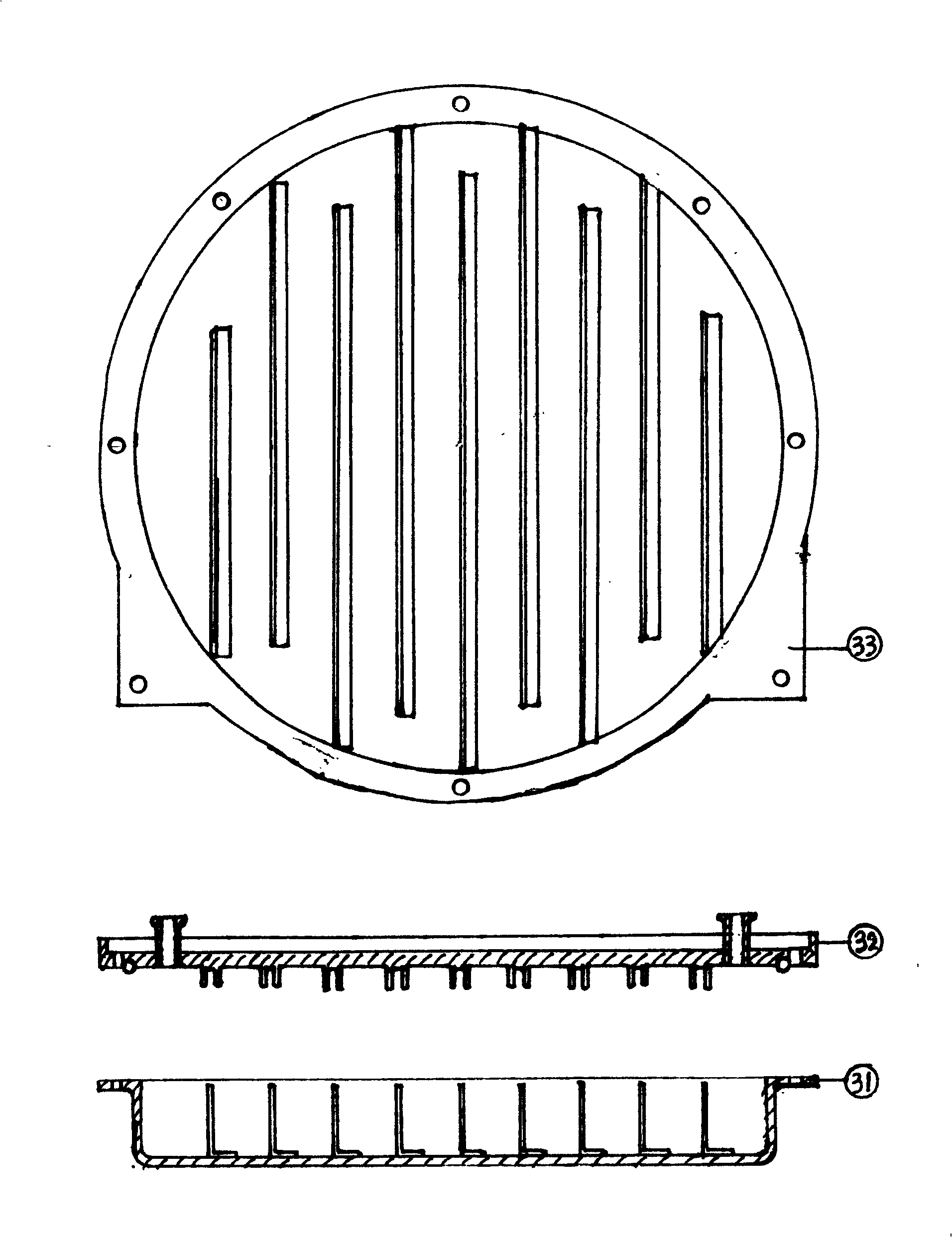

Integral locomotive air conditioner

InactiveCN1847041AConducive to miniaturization designThe whole machine is compactAir-treating devicesRailway heating/coolingAir cycleEngineering

The integral locomotive air conditioner is installed integrally in the top of locomotive via installing angles and includes indoor set and outdoor set in parallel inside one integral casing. Most of the pipe parts are inside the outdoor set to reduce noise and the interference on the inside. The integral locomotive air conditioner includes one casing, one indoor set, one outdoor set, installing angles, one indoor set wind scooper, one air intake grate connecting the air inlet of the indoor set and the top of the locomotive, and one air outlet grate connecting the air outlet of the indoor set and the top of the locomotive.

Owner:SHANDONG LONGERTEK TECH CO LTD

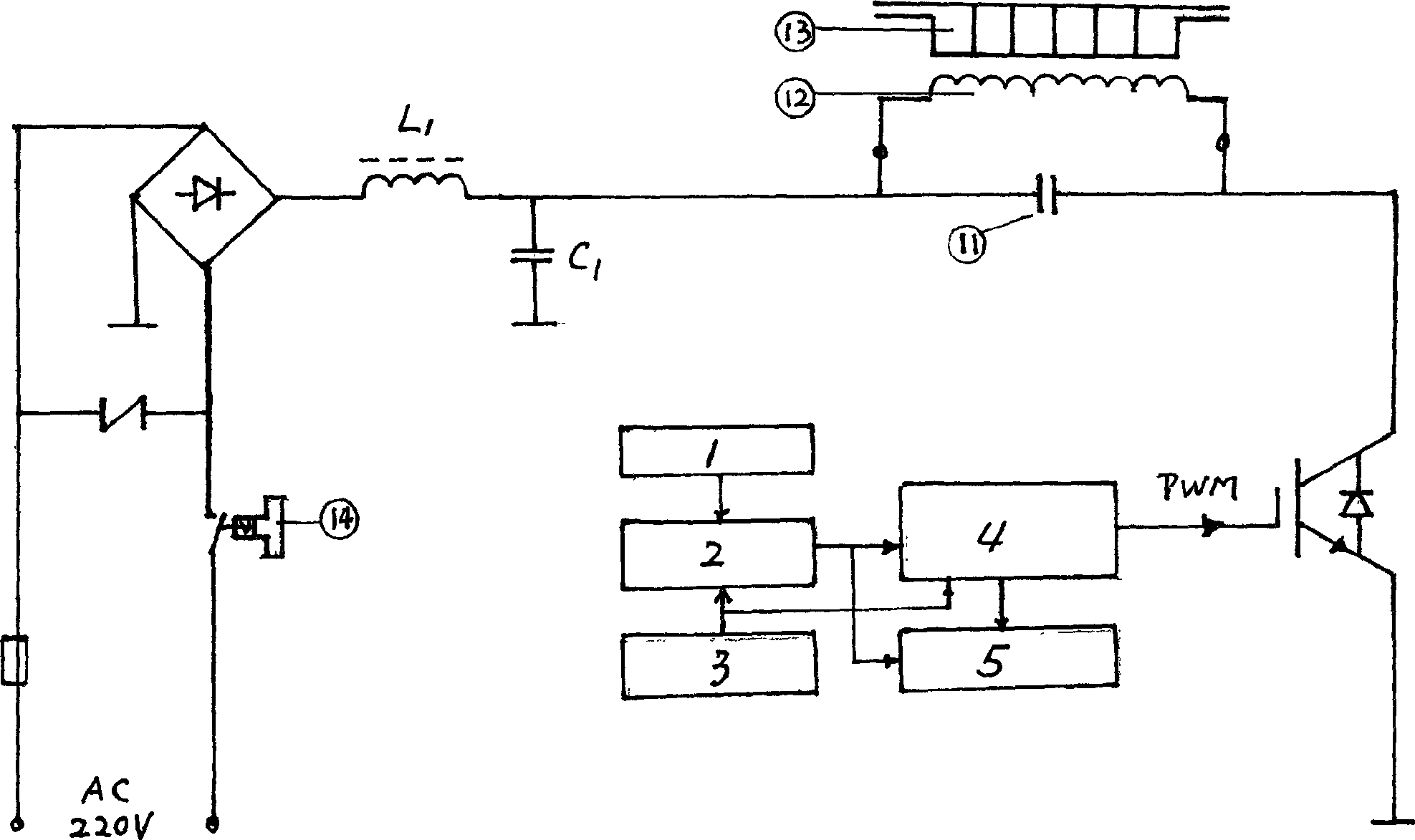

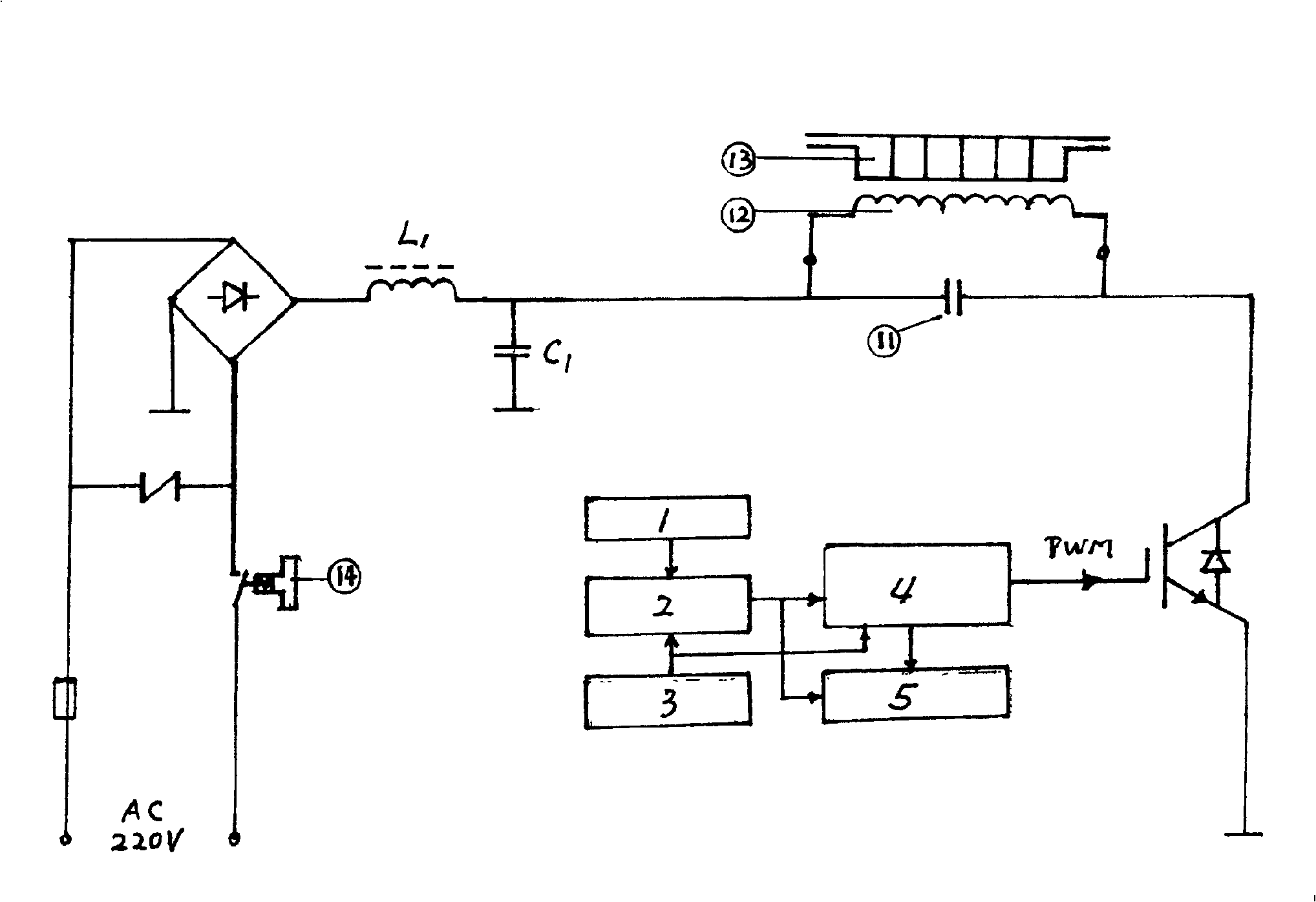

Electronic water heater

The invention relates to an electronic water heater, which comprises an power electronic frequency conversion magnetic inductive loop heating and plate type thermal interchange box. The invention realizes high thermal efficiency, easy production and low cost.

Owner:洪祥鹰

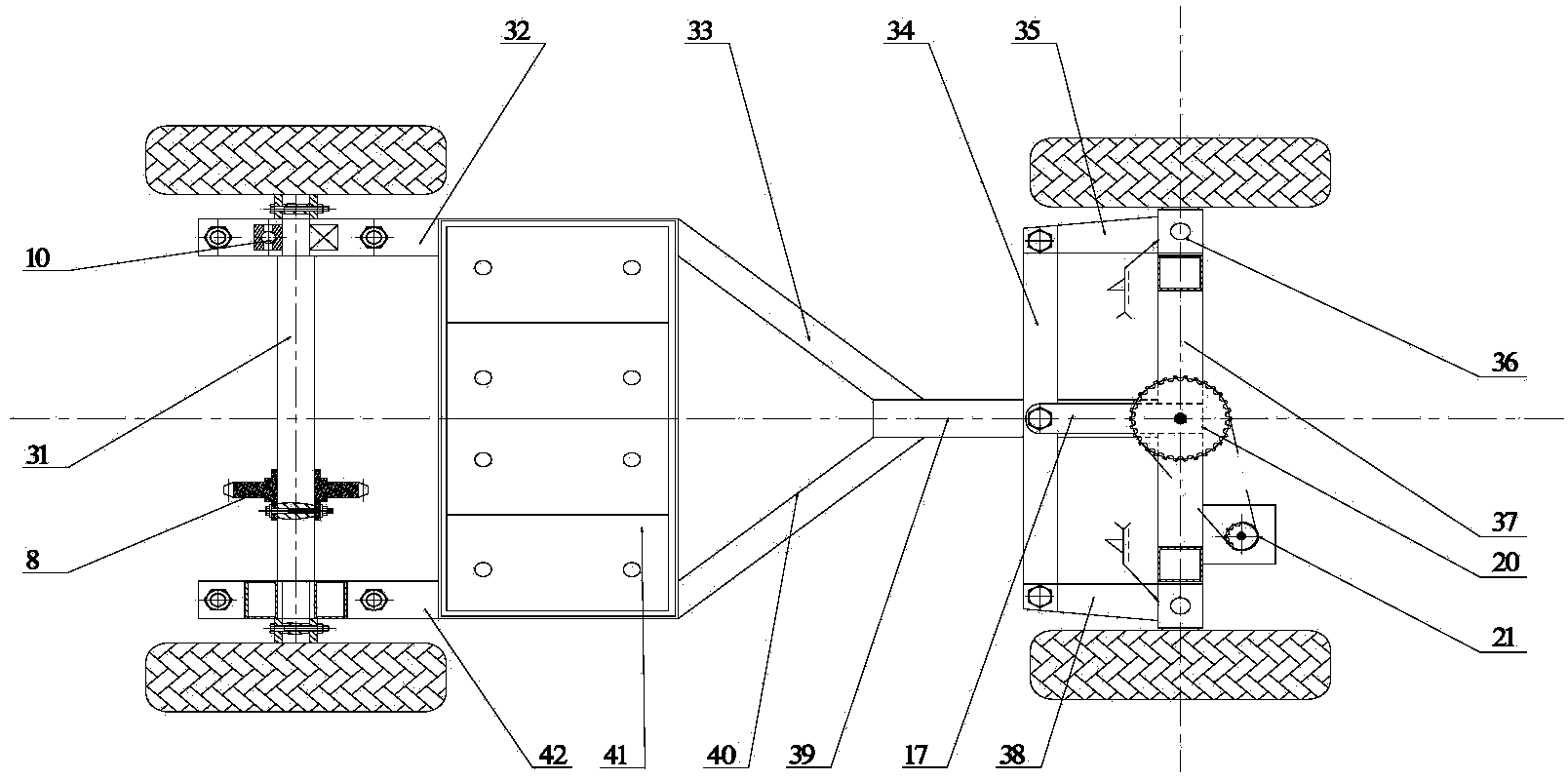

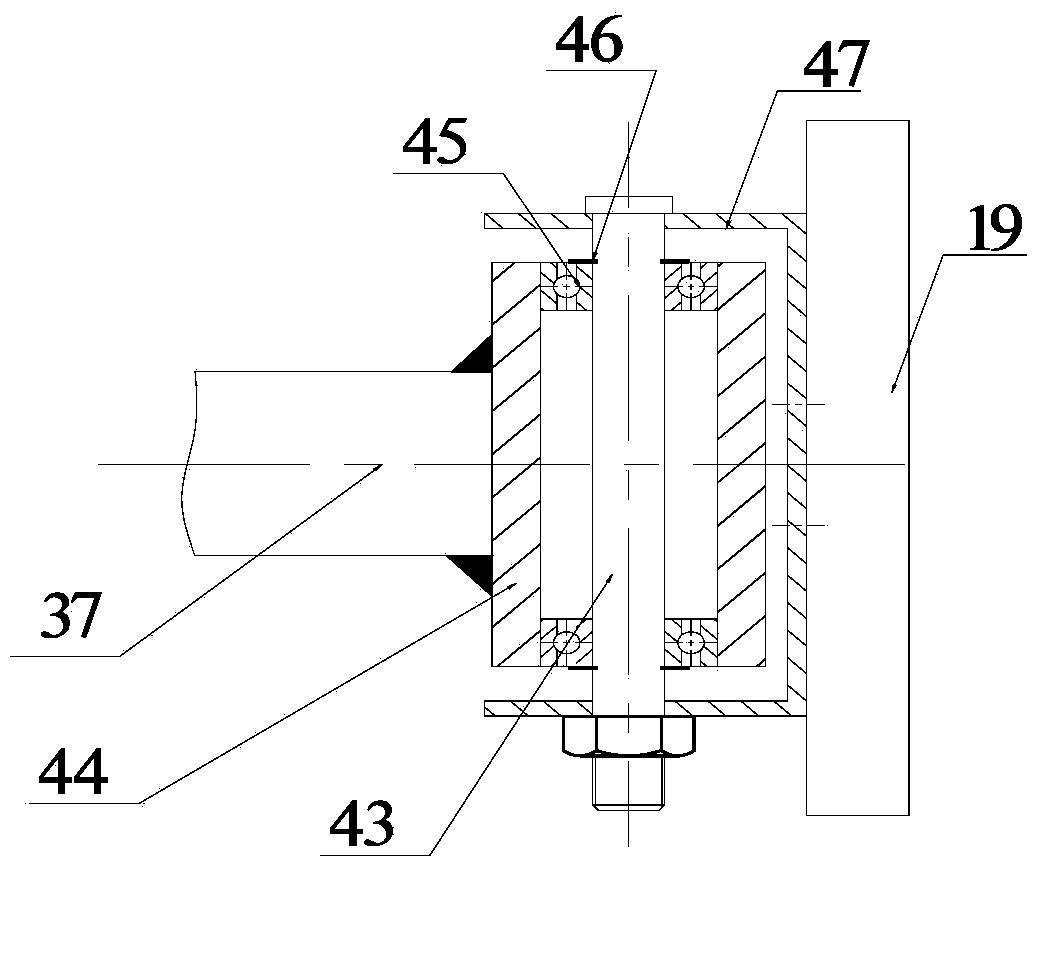

Four-line corn harvesting machine with adjustable line spacing

A four-line corn harvesting machine with adjustable line spacing is provided. A first peeling machine is assembled in the middle of a fixed spike picking device; a packing auger is assembled at the rear part of the first peeling machine; the fixed spike picking device is assembled at the front part of a rack through a fixed spike picking device supporting arm sleeve; a spike picking platform hoisting support is assembled at the lower part of the fixed spike picking device and is connected with the rack through a spike picking platform hoisting oil cylinder; a second peeling machine is assembled in the middle of a movable spike picking device; the movable spike picking device is slidingly assembled on a rack fixing sleeve through a movable spike picking device supporting arm sleeve; the movable spike picking device is slidingly supported on the spike picking platform hoisting support; one end of a spike picking platform line spacing adjusting oil cylinder is connected with the movable spike picking device and the other end of the spike picking platform line spacing adjusting oil cylinder is connected with the rack; an engine is mounted on the middle rack of the whole machine, a cab is mounted in front of the rack, a cluster box is mounted on the rear side of the rack and a field returning machine is mounted below the rack; and a lift conveyer is mounted on the rack at the right side of the cab. With the adoption of the structure, the whole machine is small and has light weight, low gravity center and hugh in-field passing capability; and the spike picking platform can be adjusted and the adaptability is improved.

Owner:SHANDONG CHANGLIN AGRI SCI EQUIP

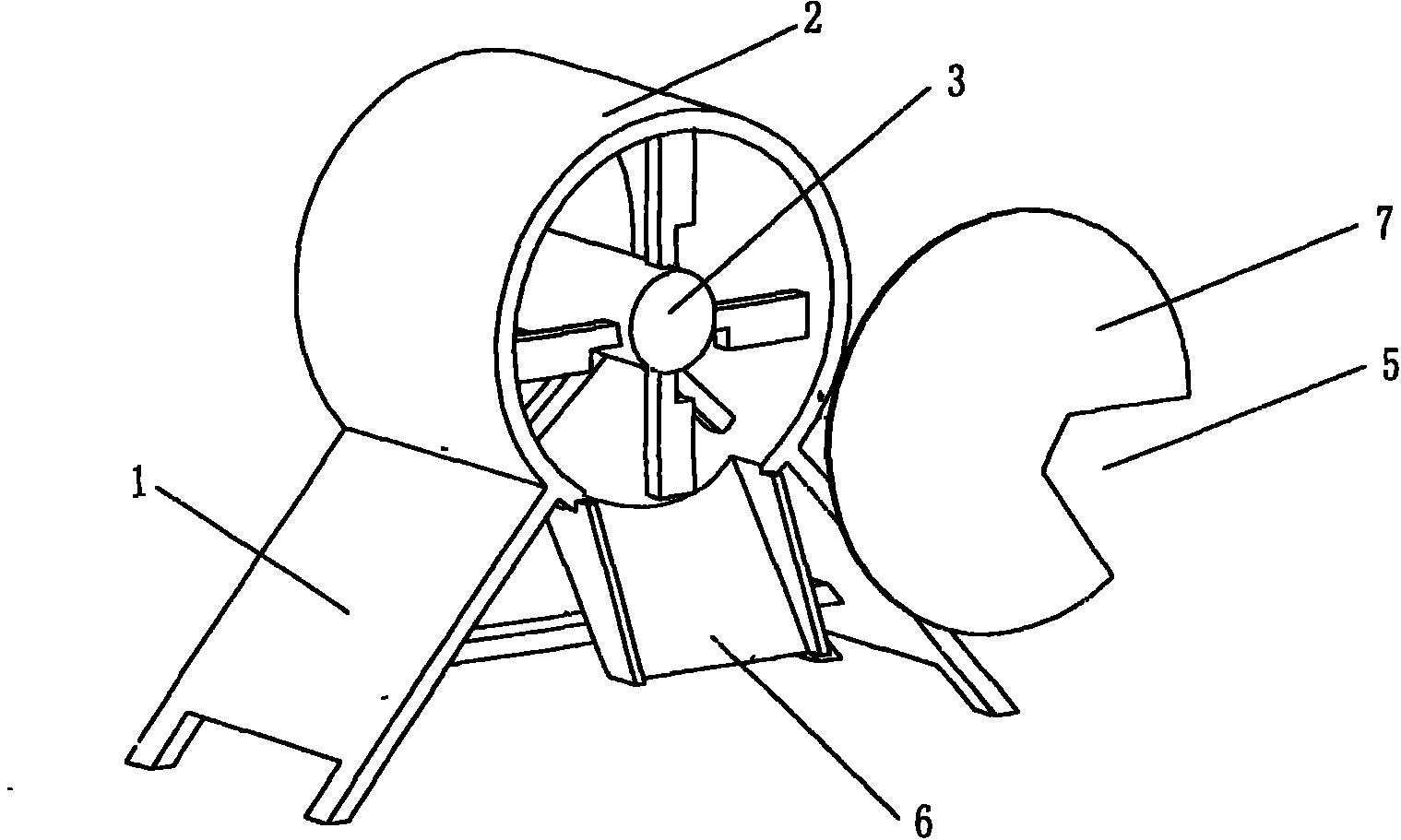

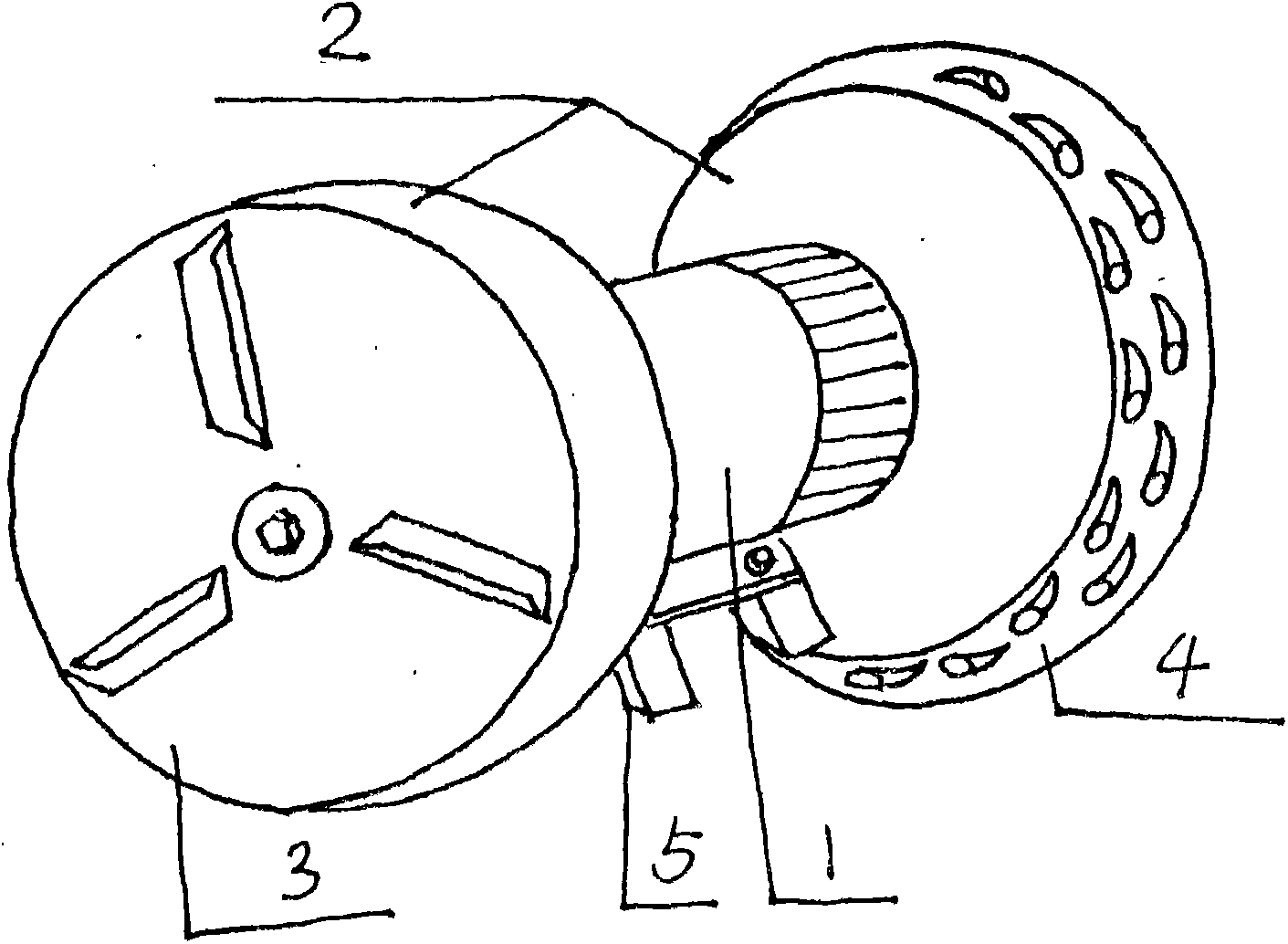

Agricultural chopper

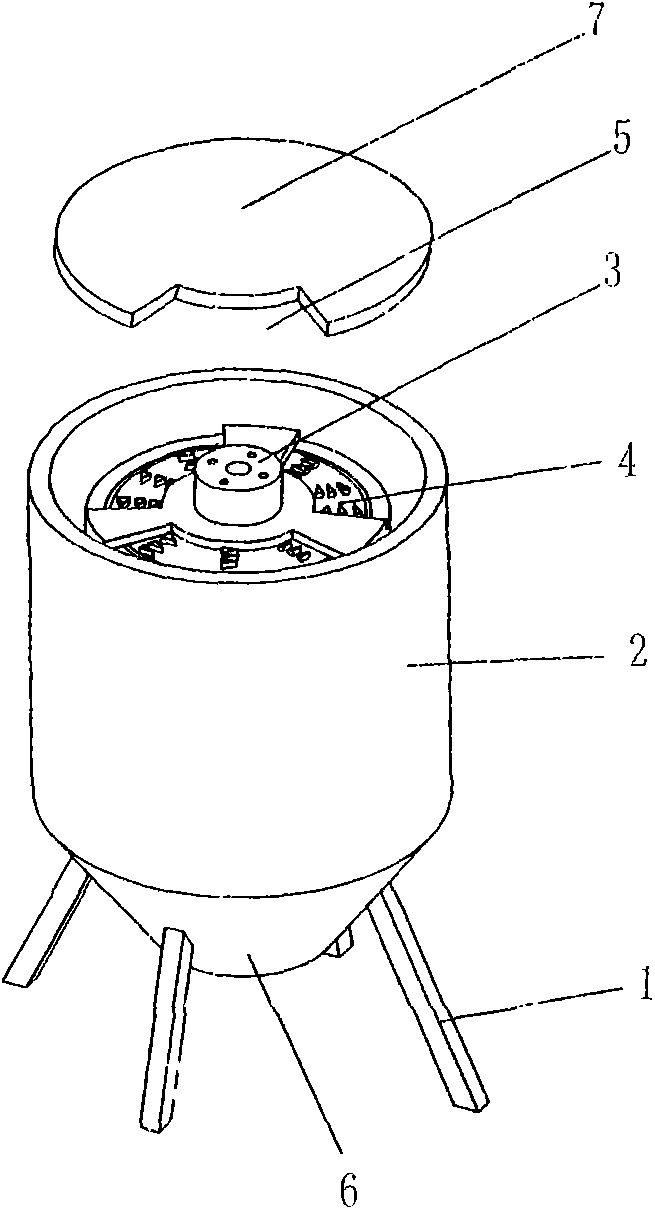

The invention discloses an agricultural chopper. The agricultural chopper comprises a frame, wherein a barrel-shaped casing is mounted on the frame; a motor is fixed on a mounting frame fixed in the casing; a cutter is fixedly mounted on a shaft of the motor; and a feeding platform is arranged on a section from the cutter to an opening of a barrel. The cutter is a single-blade cutter with the shaft of the motor fixed at the tail end of a cutter blade, or a double-edge cutter with the shaft of the motor fixed in the middle and opposite edges and axial symmetry, or a disc-shaped grinding cutter. The agricultural chopper adopts an optimization scheme, has the advantages of few parts, simple and feasible machining and maintenance, low cost, small size and random carrying by one person, and is suitable for agricultural feed chopping and rough machining of agricultural products.

Owner:陈俊行

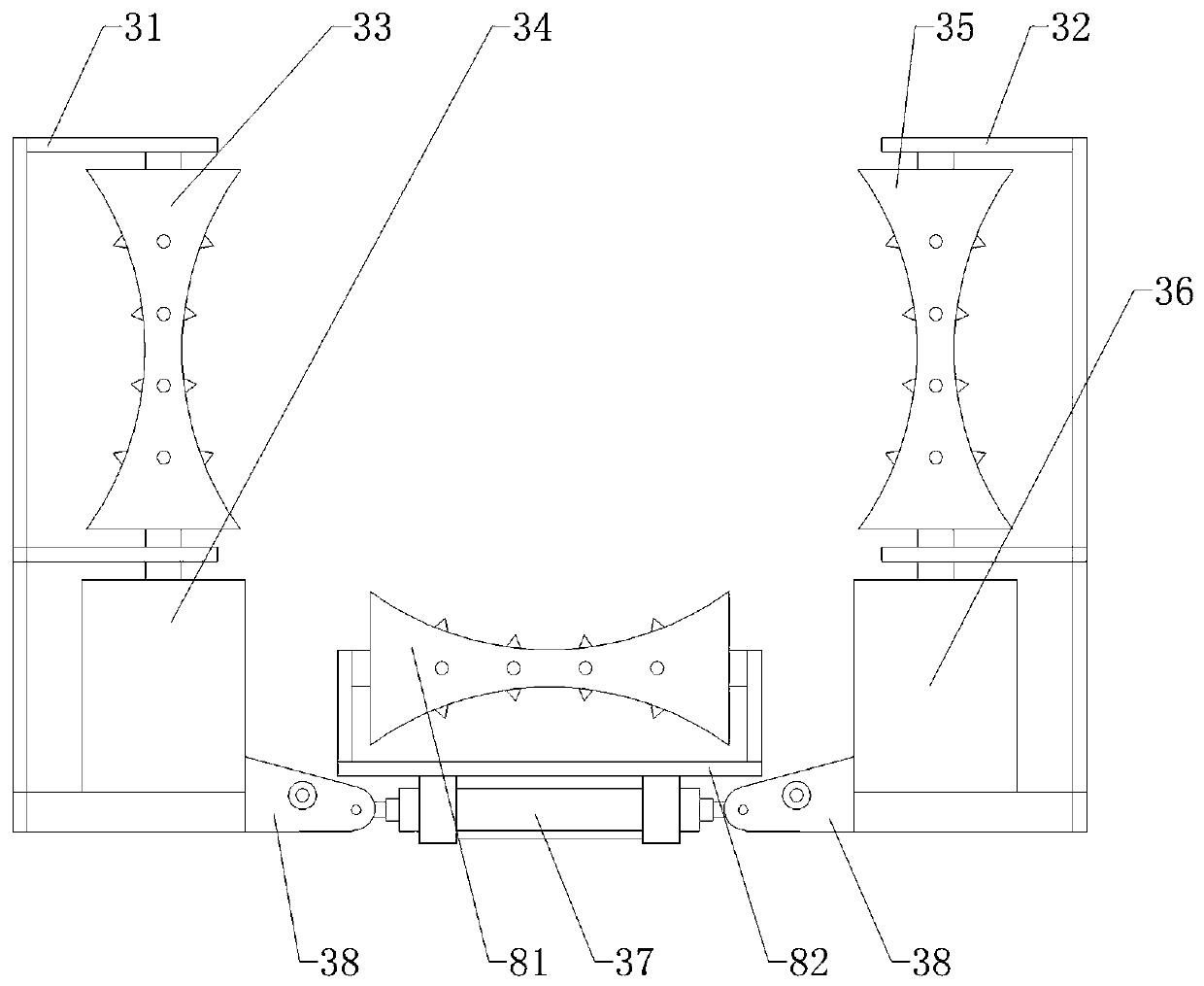

Adding device for aggregates in asphalt mixture

InactiveCN112516908AGuarantee a reasonable matchReduce vibrationTransportation and packagingMixer accessoriesStructural engineeringProcess engineering

The invention discloses an adding device for aggregates in an asphalt mixture. The device comprises a rack, a bin is arranged in the rack, a metering barrel is arranged below the bin, the metering barrel is arranged on a plurality of weighing sensors, a discharge valve is arranged on a discharge port of the bin, a metering valve is arranged at a feed port of the metering barrel, a connecting plateis arranged in the metering barrel, the connecting plate is connected with the metering valve, the metering valve comprises a sieve plate, the sieve plate is fixedly connected with a first air cylinder, a pushing shaft of the first air cylinder is connected with a valve plate, a discharging opening of the metering barrel is connected with a discharging pipe, the discharging pipe is connected withan air outlet pipe of the draught fan, and a wind power control valve is arranged on the air outlet pipe. The device has the advantages of being high in metering precision, high in automation degree,low in failure rate, capable of reducing environmental pollution and the like, can be in butt joint with an asphalt mixing plant, is stable and reliable in use condition, and can save a large amountof labor force.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

Agricultural machine for shredding, chopping and slicing

InactiveCN104339400AFew partsEasy to processMetal working apparatusAgricultural engineeringMachining

The invention discloses an agricultural machine for shredding, chopping and slicing. A barrel-shaped shell is arranged on a rack; a motor is fixedly arranged at the upper end of a mounting frame in the shell; a tool disc and a material stopping plate are fixedly arranged at two ends of a shaft of the motor; a shredding feed opening is mounted at the left upper end of the barrel-shaped shell; a chopping and slicing feed opening is mounted at the right upper end of the barrel-shaped shell; a shredding discharge opening is mounted at the left lower end of the barrel-shaped shell; a chopping and slicing discharge opening is further mounted at the right lower end of the barrel-shaped shell; material control plates are mounted at two ends of the barrel-shaped shell; a splayed vertical leg is mounted below the barrel-shaped shell; a power switch is further mounted at the side of the barrel-shaped shell. The agricultural machine for shredding, chopping and slicing is less in parts, simple and easy to process and maintain and suitable for the shredding, chopping and slicing of agricultural feeds and the rough and fine machining of agricultural products.

Owner:陈俊行

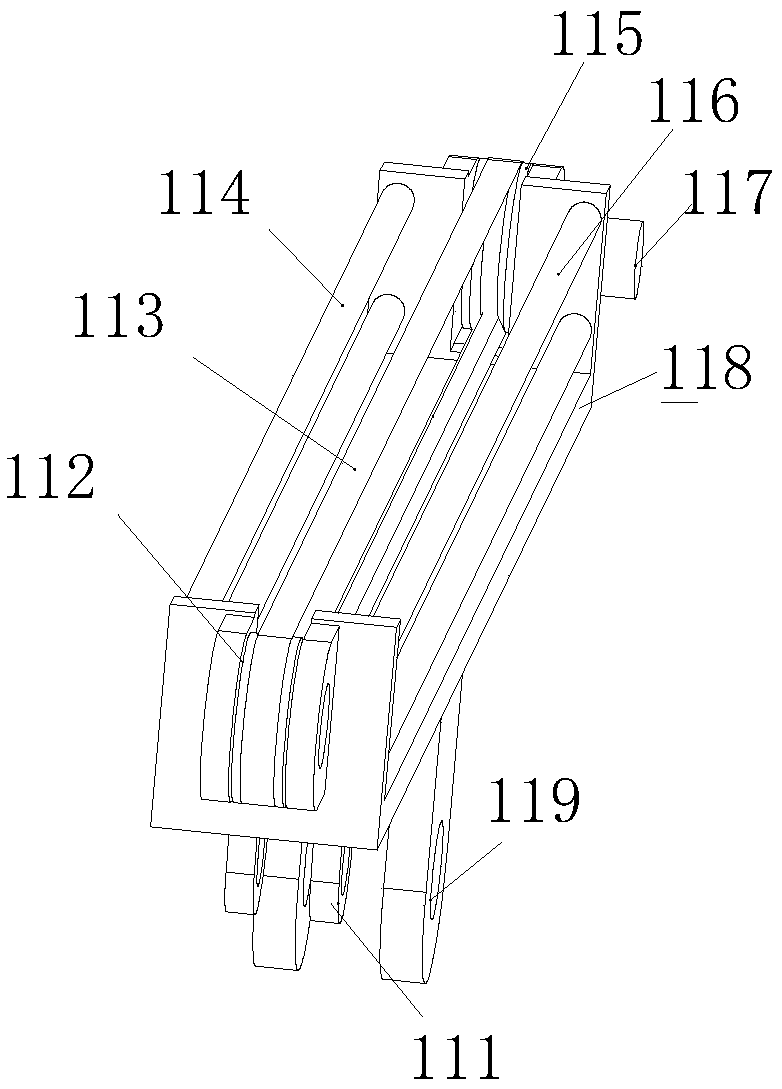

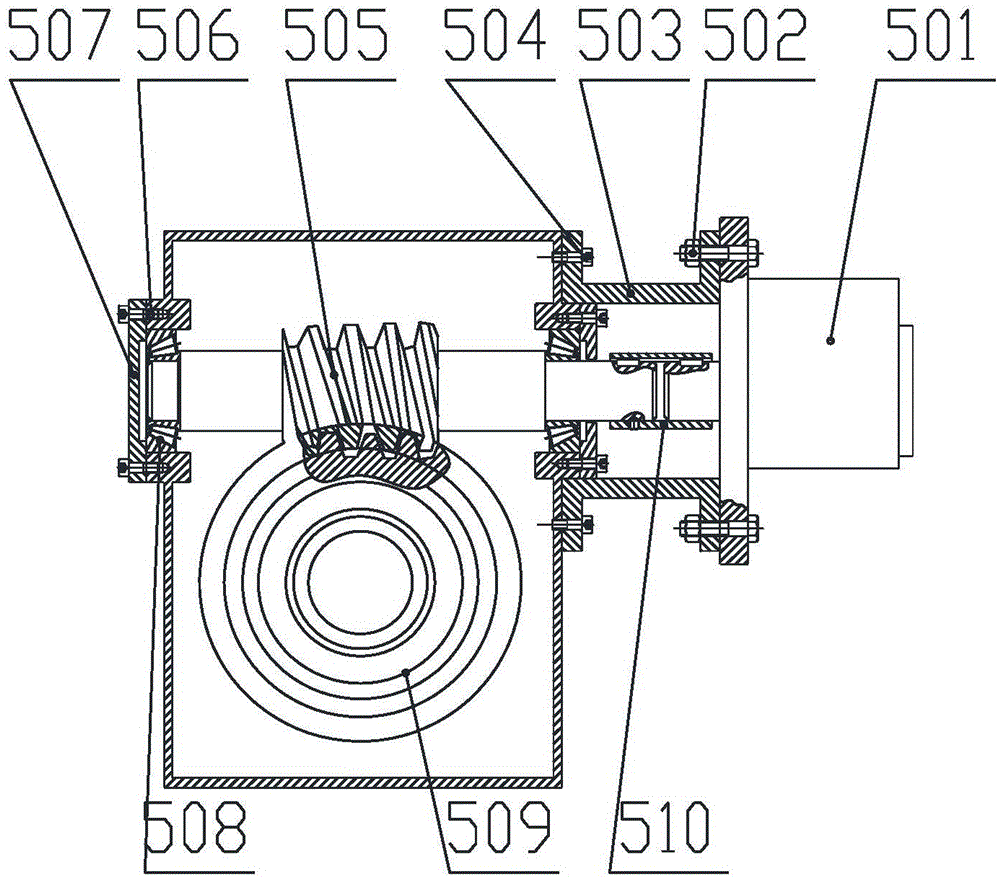

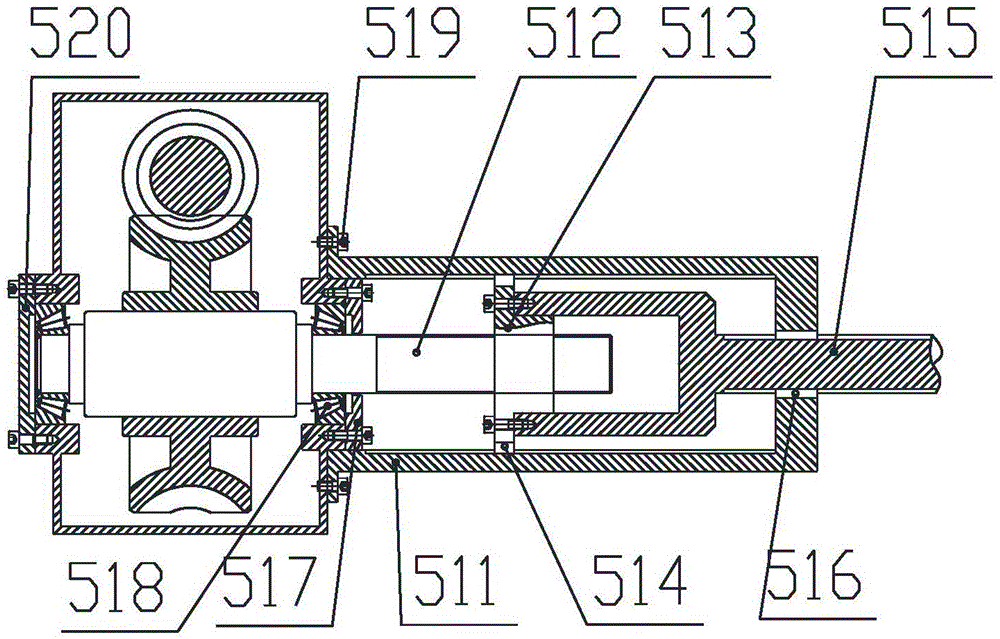

Machine with holding type collateral twisting mechanism for testing cocoon quality

The invention provides a pod quality tester having a retaining-type reeling mechanism, and relates to the pod quality tester. The invention comprises a power turning mechanism, a reeling mechanism, a recorder of number of times of dropping end. The power turning mechanism is provided with an electromotor, an infinite variable speed mechanism, a plurality of angular wheels, a small wheel transmission shaft and a wheel shaft. The shaft is provided with five small wheel revolution speed transducers in the same axial direction of rotation. The reeling mechanism is provided with a connecting pipe. The infinite variable speed mechanism is connected with and drives the reeling input shaft of the reeling mechanism. The bearings of the jacket of the reeling input shaft are joined with and turn relative to the reeling mechanism and the inner ring of the connecting pipe of the reeling mechanism respectively. The end of the reeling input shaft inside the reeling mechanism is connected with and drives the reeling output shaft. The external rim of the connecting pipe of the reeling mechanism is provided with a retaining piece. The ratio of the rotation rates of the reeling input shaft and the reeling output shaft is 1.000:0.998. The machine can adjust the rotation bevels of the reeling input and output shafts freely, and is suitable for mini-type quality testers and can twist silk and take silk from the small wheel successfully without overlapping or joggling the silk.

Owner:SICHUAN RES INST OF SILK SCI +1

Machine with holding type collateral twisting mechanism for testing cocoon quality

The invention provides a pod quality tester having a retaining-type reeling mechanism, and relates to the pod quality tester. The invention comprises a power turning mechanism, a reeling mechanism, a recorder of number of times of dropping end. The power turning mechanism is provided with an electromotor, an infinite variable speed mechanism, a plurality of angular wheels, a small silk unreeling wheel transmission shaft, a silk unreeling shaft and the silk unreeling shaft is equipped with five small silk unreeling revolution speed transducers in the same rotated direction with the silk unreeling shaft. The shaft is provided with five small wheel revolution speed transducers in the same axial direction of rotation. The reeling mechanism is provided with a connecting pipe.The infinite variable speed mechanism is connected with and drives the reeling input shaft of the reeling mechanism. The bearings of the jacket of the reeling input shaft are joined with and turn relative to the reeling mechanism and the inner ring of the connecting pipe of the reeling mechanism respectively. The end of the reeling input shaft inside the reeling mechanism is connected with and drives the reeling output shaft. The external rim of the connecting pipe of the reeling mechanism is provided with a retaining piece. The ratio of the rotation rates of the reeling input shaft and the reeling output shaft is 1.000:0.998. The machine can adjust the rotation bevels of the reeling input and output shafts freely, and is suitable for mini-type quality testers and can twist silk and take silk from the small silk unreeling wheel successfully without overlapping or joggling the silk.

Owner:SICHUAN RES INST OF SILK SCI +1

Line corridor cleaning device

ActiveCN107360871BThe whole machine is compactEasy to use and flexibleCuttersCutting implementsSimulationStructural engineering

The invention provides a line corridor cleaning device which comprises a frame. The line corridor cleaning device is characterized in that the device further comprises two vertical tree climbing components, a sawing component is connected at the bottom of the upper tree climbing component, a toppling direction control device is arranged between the sawing component and the lower tree climbing component, the toppling direction control device controls the upper tree climbing component to swing relative to the lower tree climbing component, and a traveling component for controlling the traveling direction of a whole machine is connected at the bottom of the lower tree climbing component. The line corridor cleaning device has the advantages that the device is small in size and flexible and convenient to use and can automatically travel, trees can be trimmed as required, and toppling direction directions of the trees can be controlled, so that lines are not damaged.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QINGZHOU POWER SUPPLY CO +2

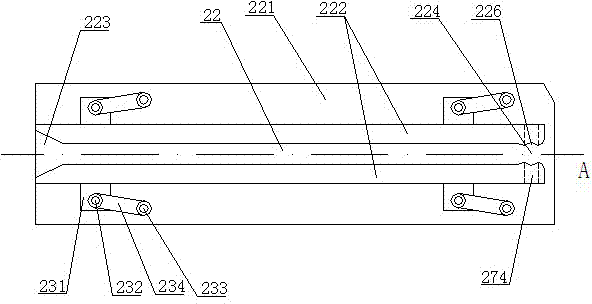

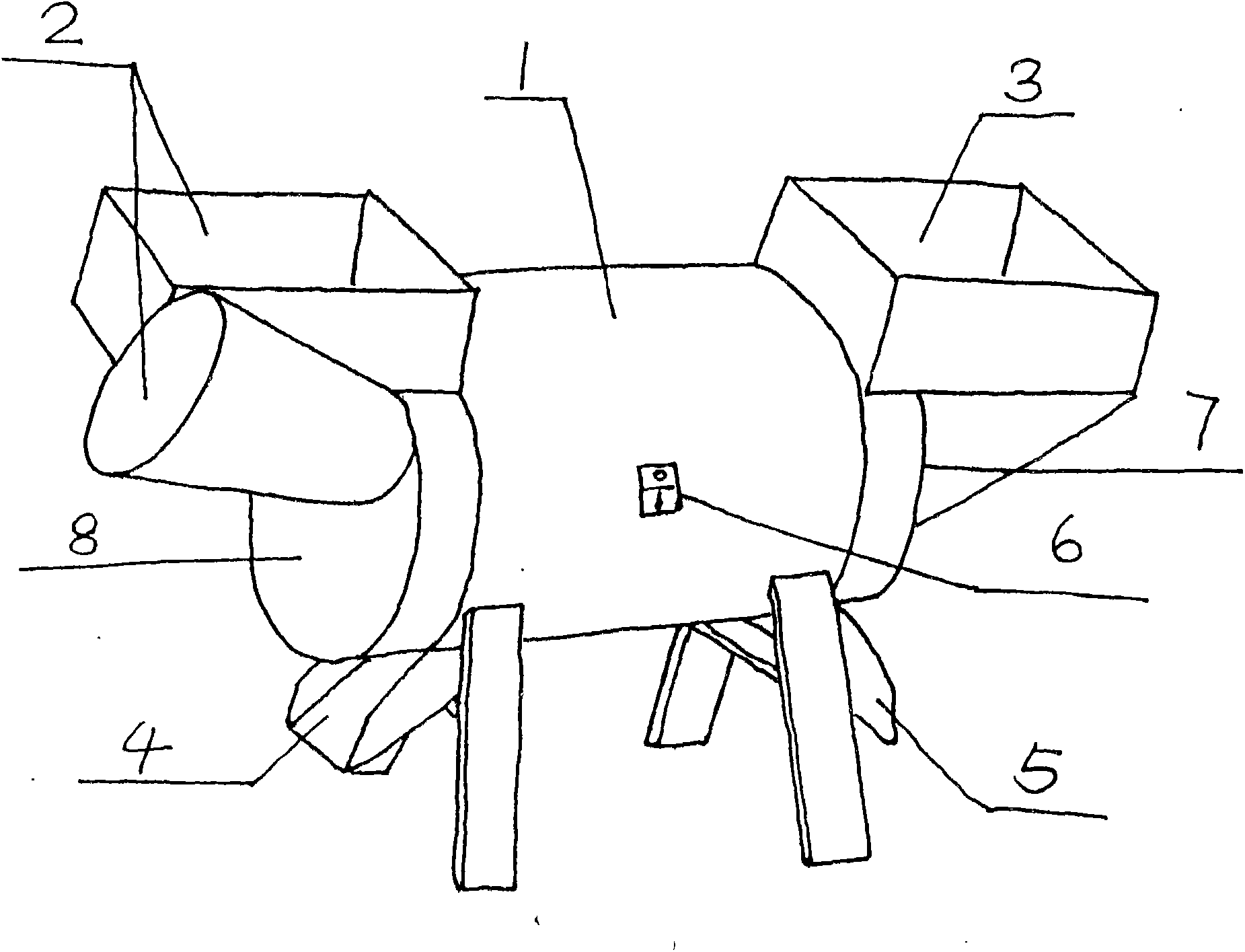

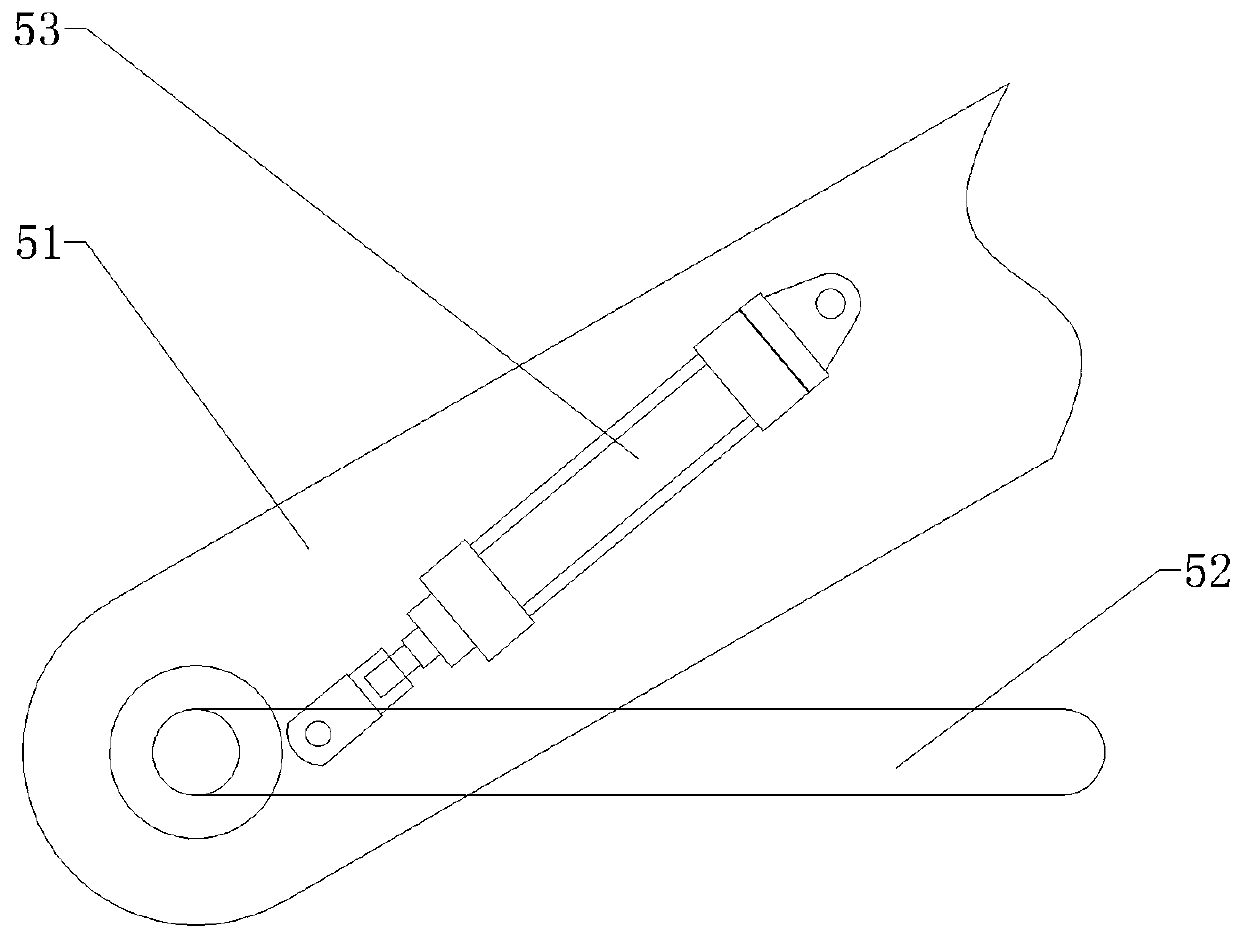

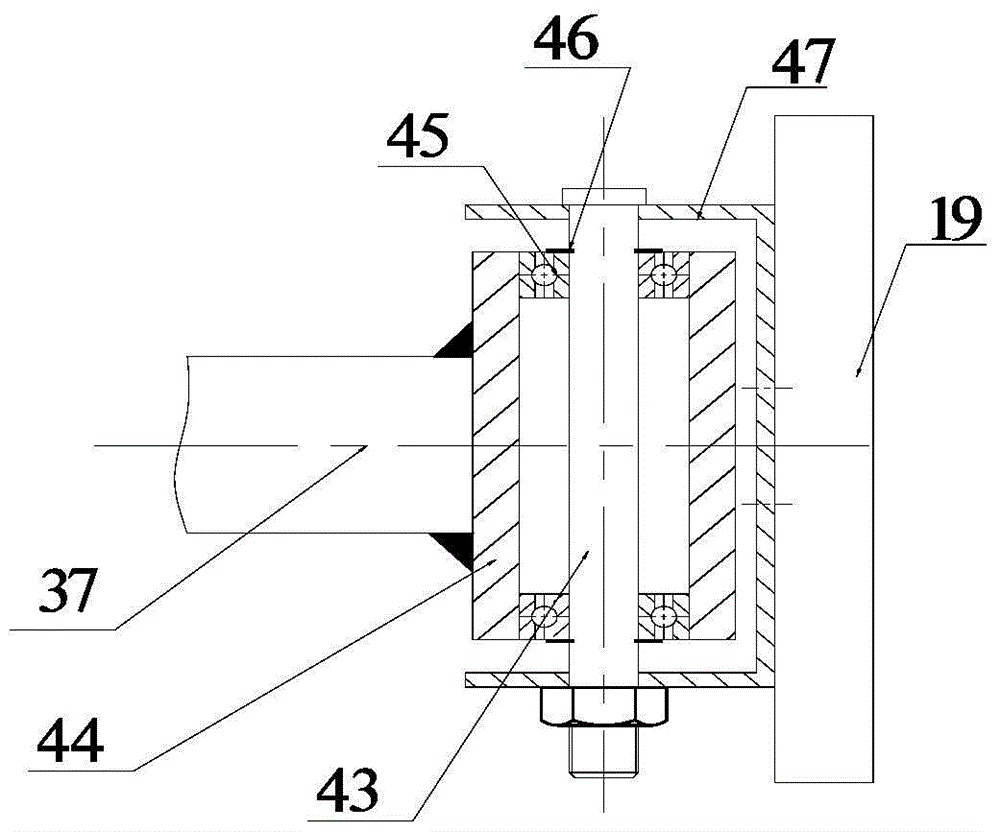

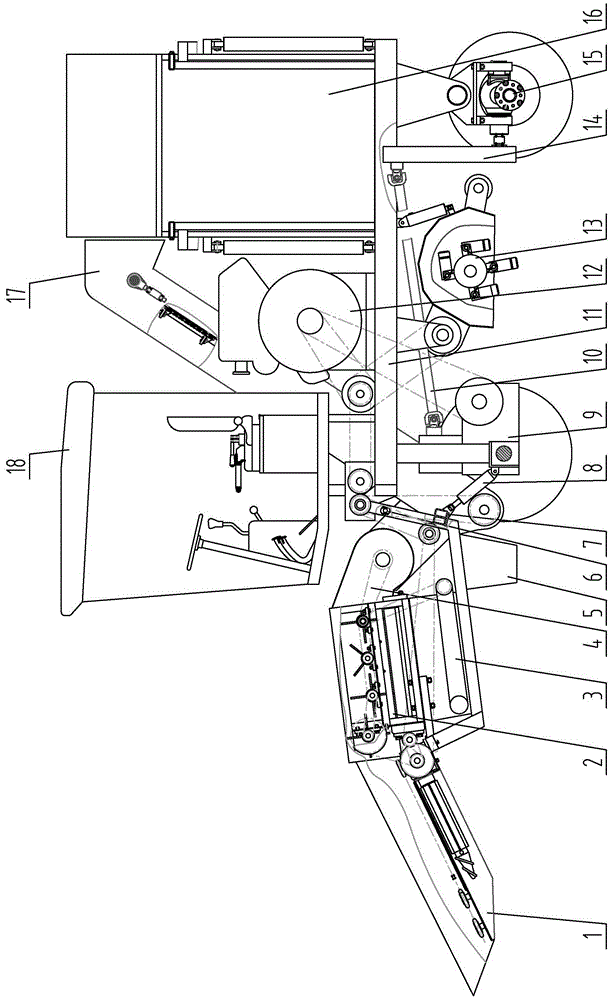

A kind of fertilizer grabbing soil covering machine

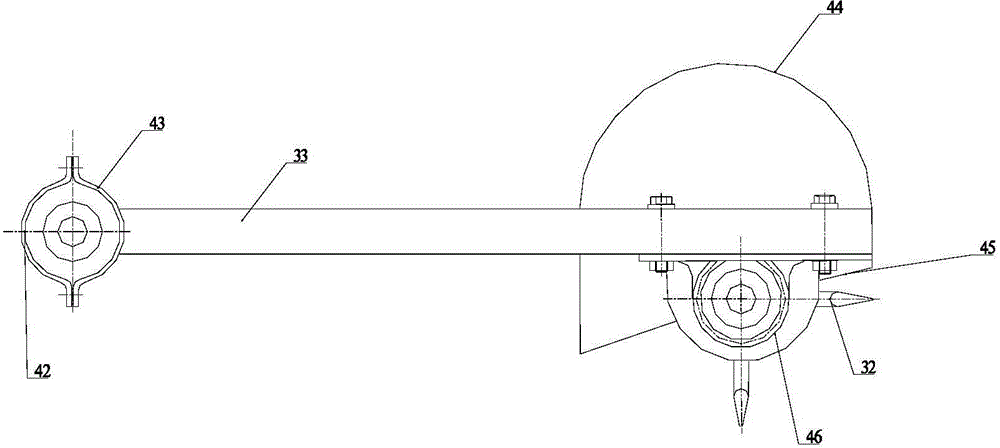

ActiveCN104521352BReduce labor intensityIncrease productivitySpadesPloughsDrive wheelReduction drive

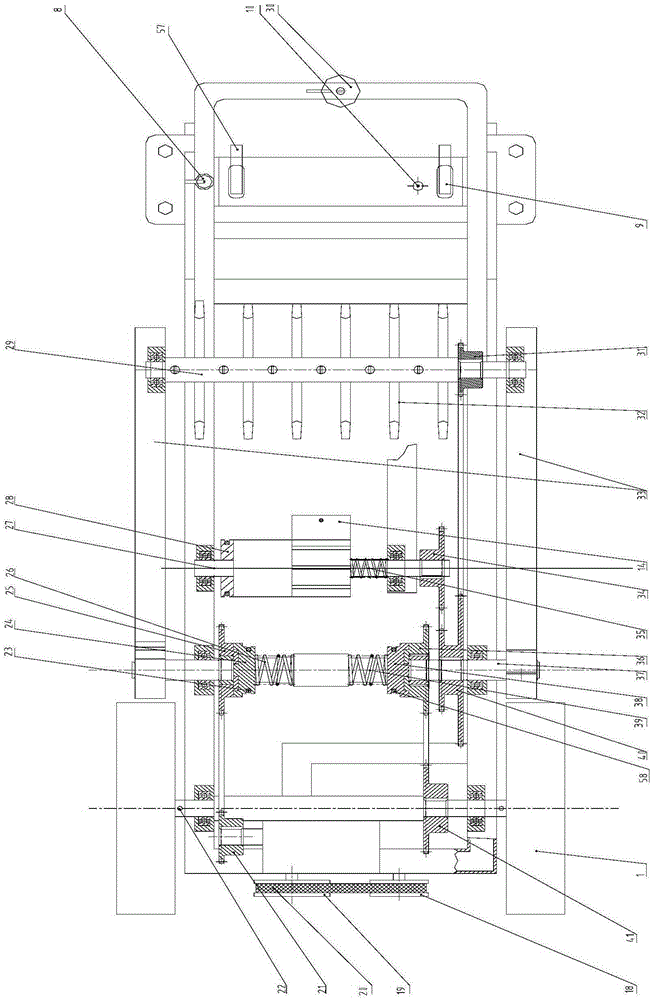

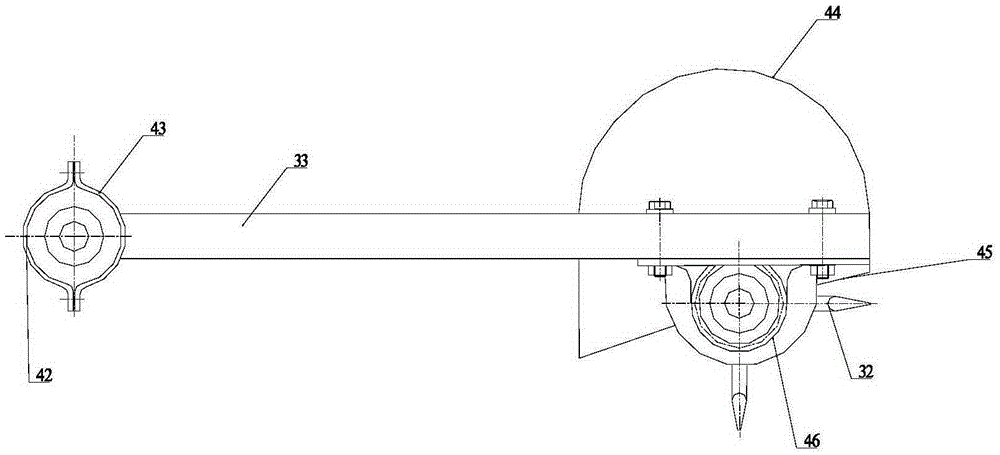

The invention discloses a fertilizer spreading, soil grabbing and soil covering machine comprising a frame (5), and a driving and travelling system, a transmission system, a fertilization system, a soil loosening and covering system and a control system which are arranged on the frame. The driving and travelling system comprises a gasoline engine (4), driving wheels (1) and an universal rear wheel (16). The transmission system comprises a speed reducer (2), a power output gear (21), a tension wheel (3), a first jaw clutch (24), a travelling driving gear (36), a main shaft (37), a main shaft gear (25), a travelling shaft, a travelling shaft gear (41), a second jaw clutch(38), a double transmission gear (40) and a soil-loosening shaft gear (31). A dynamic wheel (19) of the gasoline engine, the tension wheel and a speed reducer pulley (18) of the speed reducer are subjected to transmission with a synchronizing belt. The fertilizer spreading, soil grabbing and soil covering machine is easy to control. According to the invention, fertilizing, soil loosening and soil covering functions are integrated, and the machine has high working efficiency.

Owner:HUNAN AGRICULTURAL UNIV

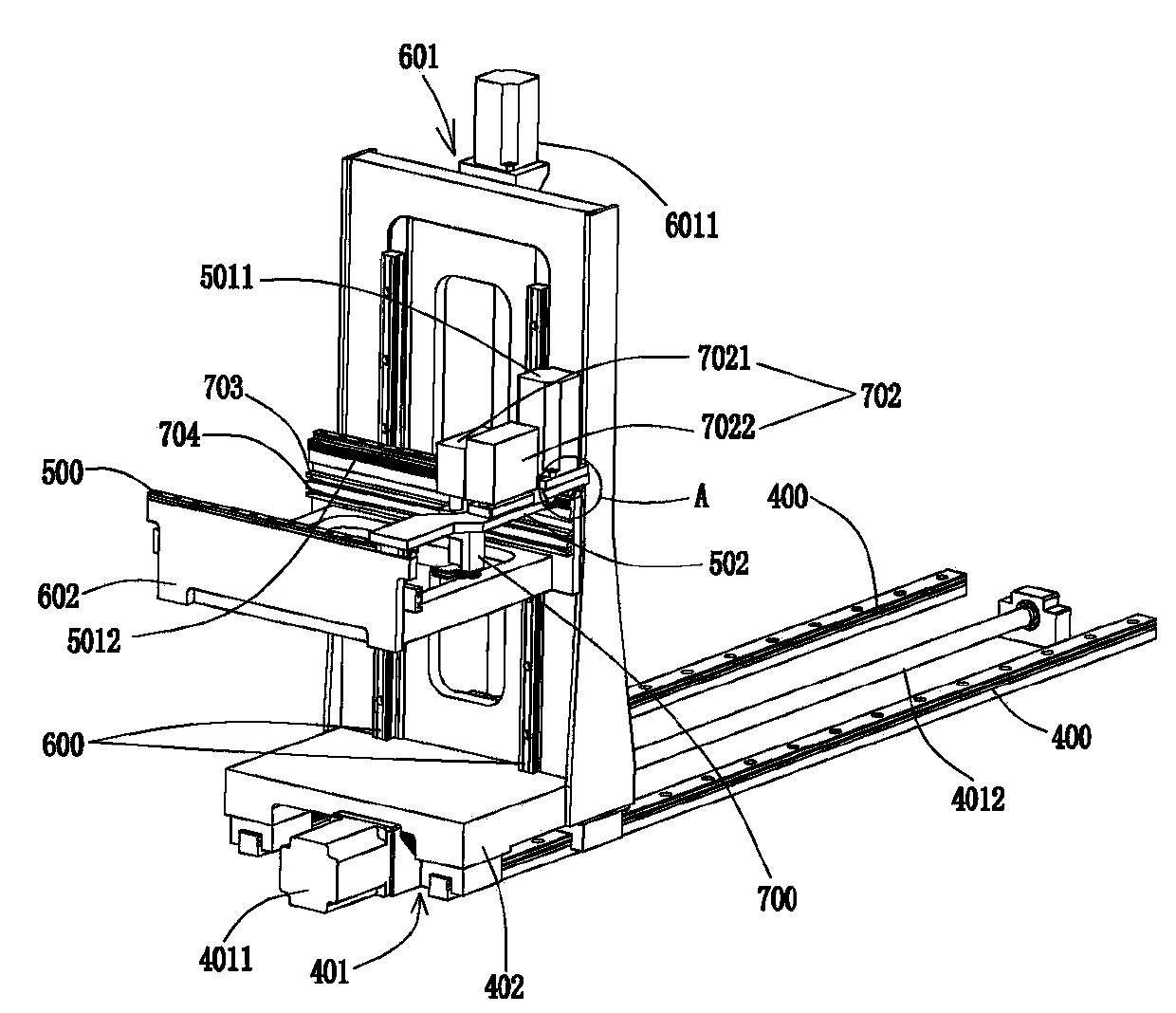

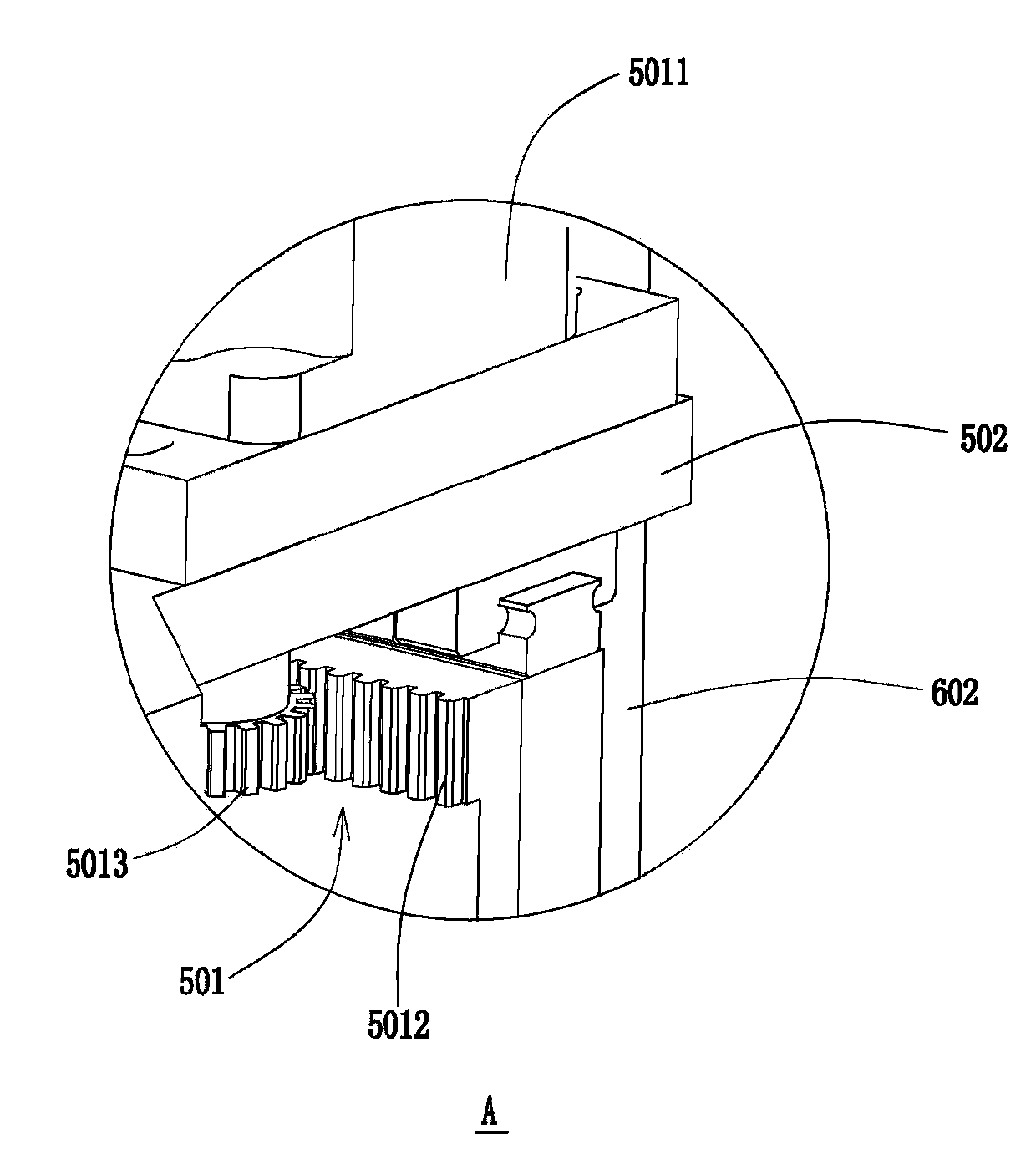

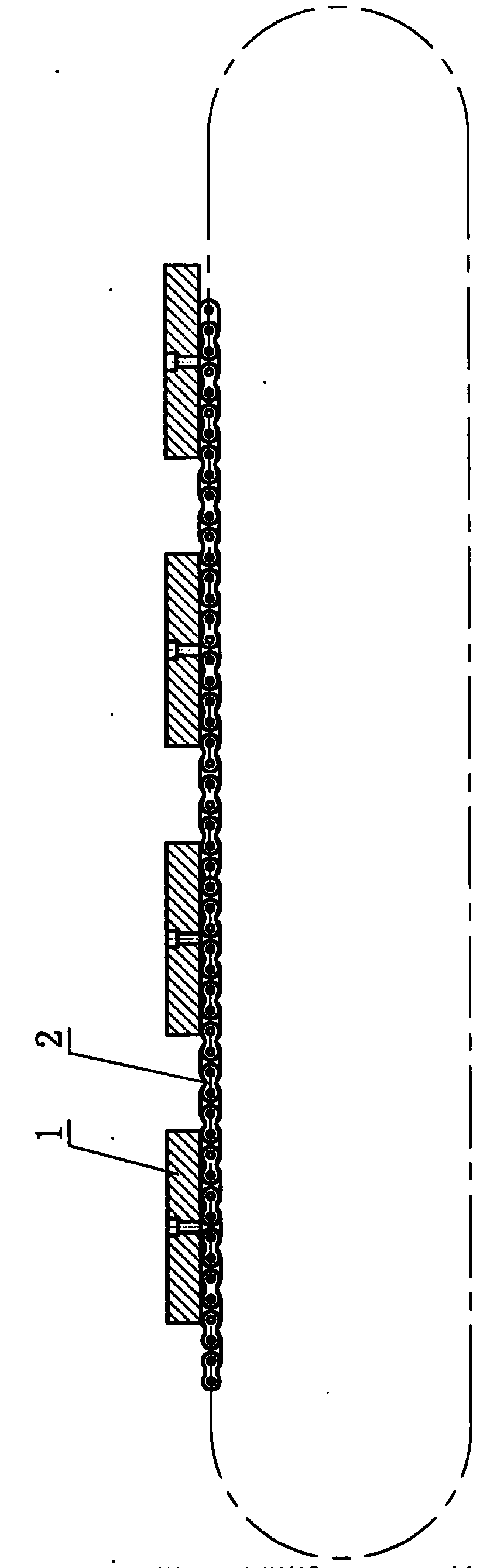

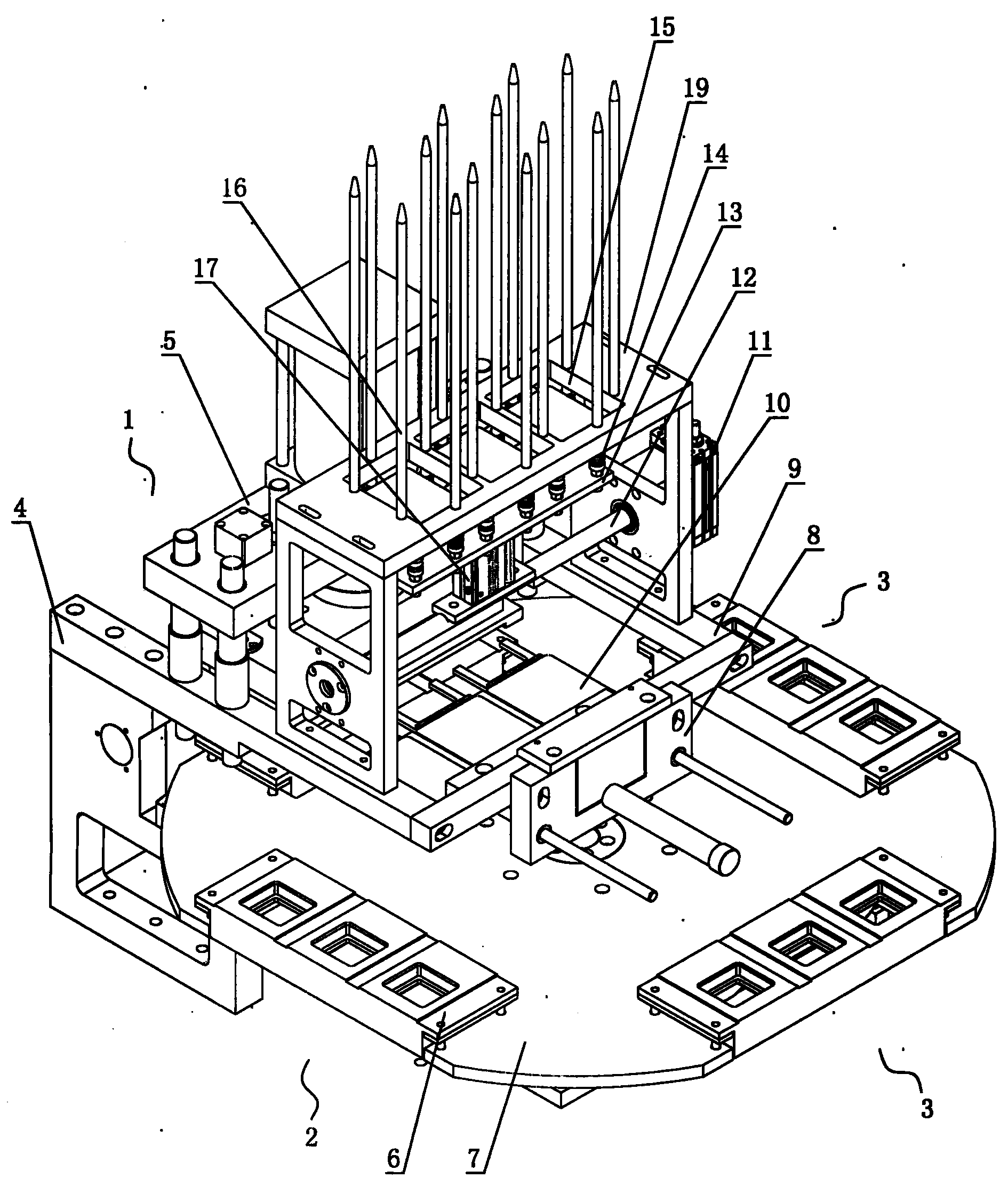

Full automatic crystalline grain detection and sorting all-in-one machine

This application discloses a fully automatic grain detection and sorting integrated equipment. The equipment consists of a wafer workbench, a sorting workbench, a detection workbench, a transportation system, a wafer workbench pushing device, and a sorting workbench pushing device. , testing workbench pushing device, swing arm mechanism, and chip sorting material warehouse, the above-mentioned nine main parts are composed. This application improves the traditional layout and mechanical structure in the prior art. Through the transport transmission system and the push device, the discs can be freely moved in and out between the workbench and the chip sorting warehouse, and the corresponding discs can be picked and placed synchronously. At the same time, the transport transmission system has two buffer positions, which can reduce the exchange time between the disks to be sorted and the disks after sorting, and the disks to be inspected and the disks after inspection. , thereby speeding up the time and efficiency of grain sorting and inspection. It has the characteristics of high-efficiency chip replacement, compact machine, compact structure, good machine stability, and good expandability of the chip sorting warehouse.

Owner:广东志成华科光电设备有限公司

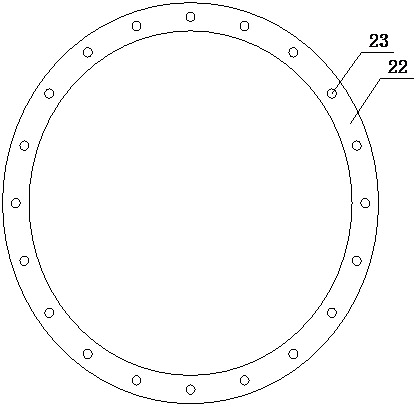

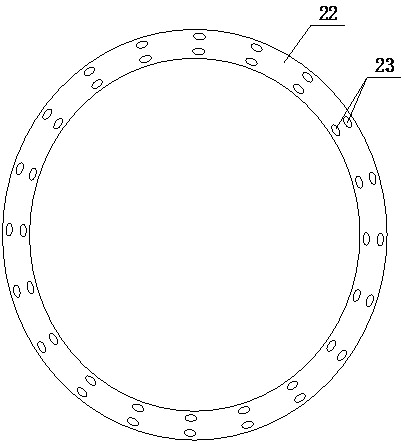

Molding mechanism of paper plastic packaging machine

InactiveCN103274082BRealize automatic feedingSmall heat seal modulusWrapping material feeding apparatusWrapper twisting/gatheringPlastic packagingPaperboard

The invention discloses a molding mechanism of a paper plastic packaging machine. The molding mechanism of the paper plastic packaging machine comprises a rack, heat-sealing molds, a plastic blister material discharging station, material feeding stations and a heat-sealing station, and is characterized in that a rotation plate is arranged on the rack, the rotation plate is connected with a power source, the heat-sealing molds are distributed on the rotation plate in the circumferential direction, the heat-sealing molds on the rotation plate correspond to the plastic blister material discharging station, the material feeding stations and the heat-sealing station, and the heat-sealing station is provided with a heat-sealing device. According to the molding mechanism of the paper plastic packaging machine, the heat-sealing molds are arranged on the rotation plate and sent to different stations through rotation of the rotation plate, and finally heat sealing is carried out on a plastic blister and a paperboard on each heat-sealing mold by the heat-sealing device. The molding mechanism of the paper plastic packaging machine is small in number of the required heat-sealing molds, low in production cost, compact in structure, small and exquisite in whole machine and convenient to install and transport.

Owner:WENZHOU BOYANG PACKAGING MACHINERY

An electric remote control electrostatic adjustable profiling spray method

ActiveCN104351156BReduce labor intensityImprove productivityPressurised distribution of liquid fertiliserInsect catchers and killersDrive wheelSteering wheel

The invention discloses an electric remote-control electrostatic adjustable profile modeling spray method which is to implement spray operation by an electric remote-control electrostatic adjustable profile modeling sprayer. The sprayer comprises a frame as well as a power system, a steering system and a spraying system on the frame, wherein two driving wheels in the power system serve as rear wheels; two steering wheels in the steering system serve as front wheels; the spraying system comprises a water tank (1), a three-way valve (3), a water pipe (11), a water pump (14), a spray lance (28), a sprayer (30) and a spray lance control apparatus; a four-side active rocker mechanism is composed of a left supporting rod mechanism, a right supporting rod mechanism, an upper guide block and a lower guide block; the steering system comprises a steering motor (21), a steering chain wheel (20), a guide plate (17), steering wheels (19), a steering wheel connecting mechanism (36) and a steering mechanism. The electric remote-control electrostatic adjustable profile modeling spray method is easy to implement, capable of being applied to various environments and high in spraying efficiency.

Owner:HUNAN AGRICULTURAL UNIV

Secondary cable alignment device

ActiveCN101839956BAvoid mutual interferenceAccurate judgmentElectrical testingCable installation apparatusElectrical batteryLithium battery

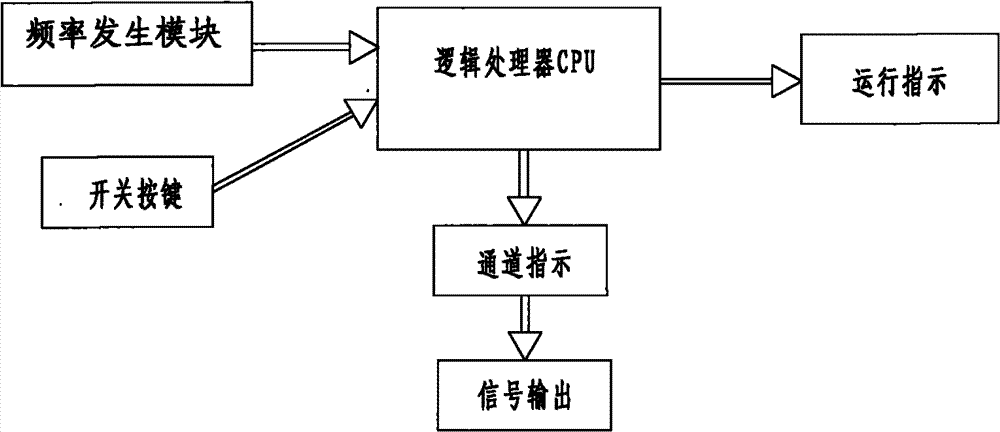

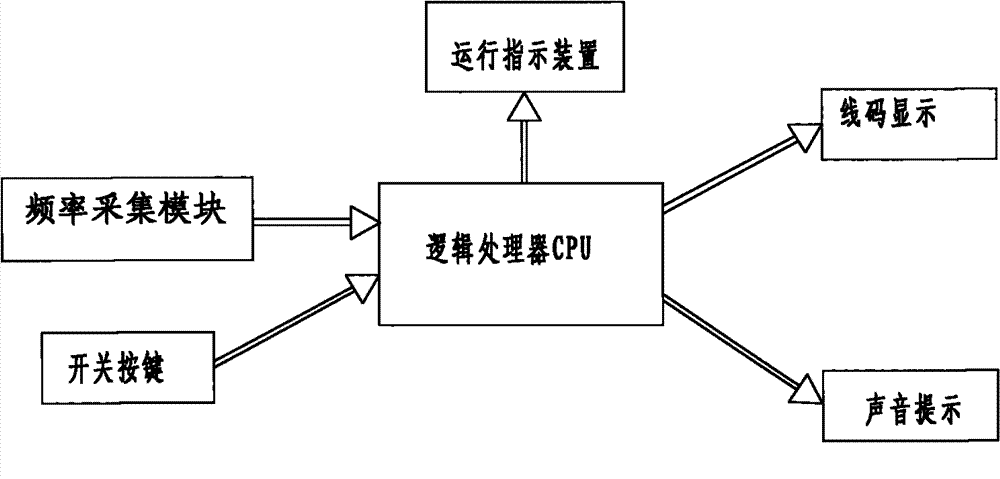

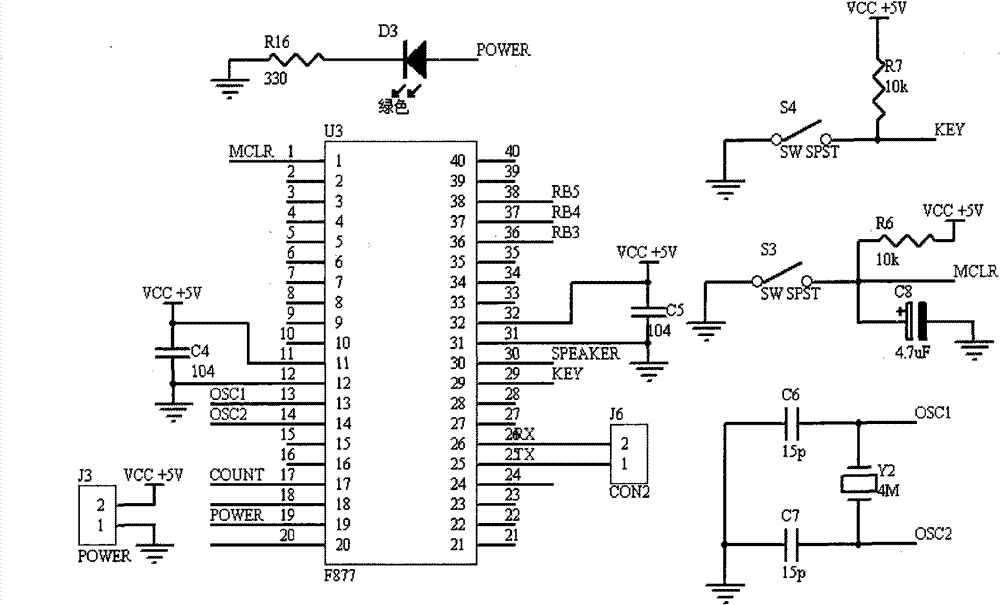

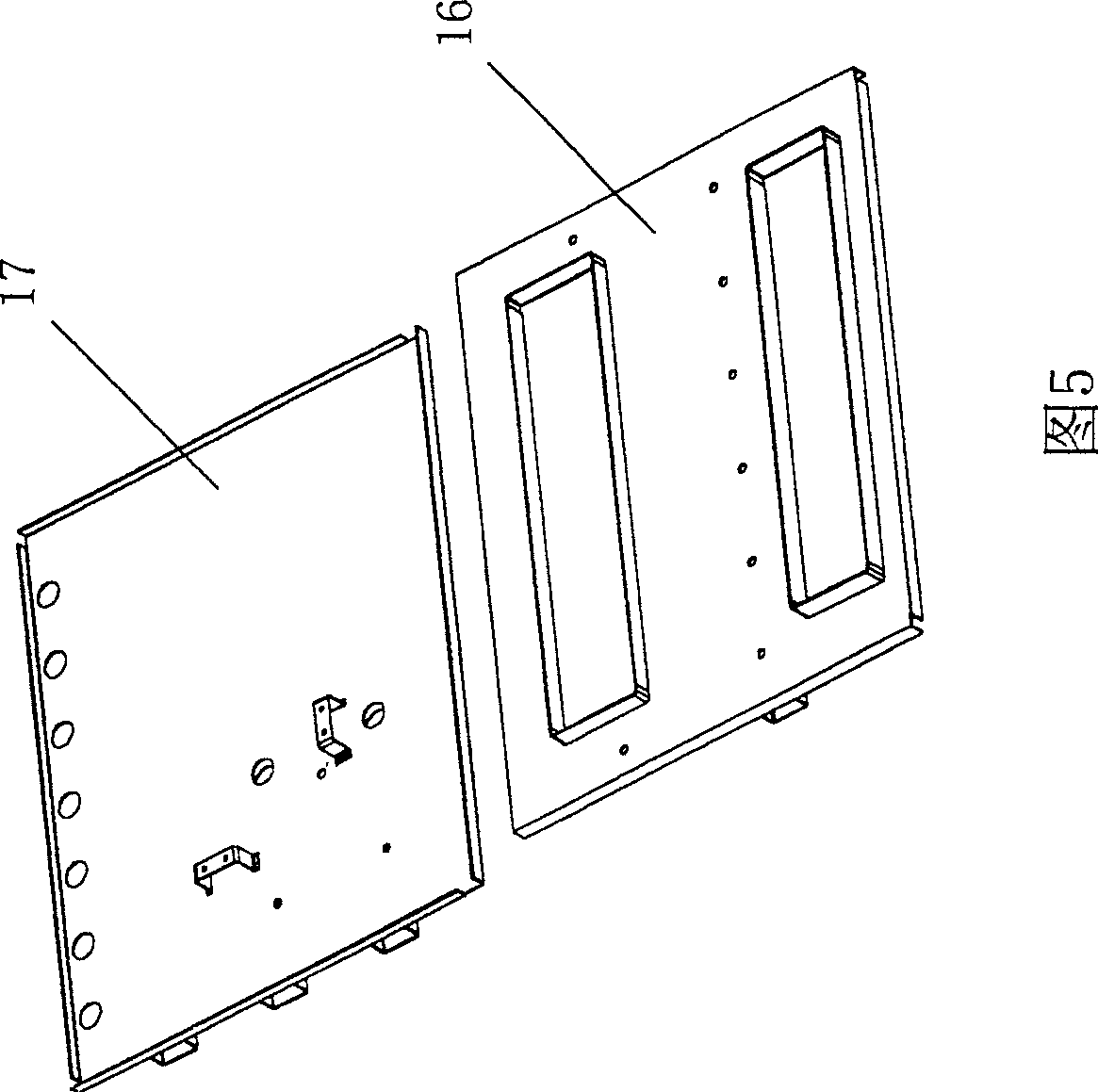

The invention relates to a secondary cable alignment device, which mainly comprises a host, a slave, a host cable clamp and a slave cable clamp. The secondary cable alignment device has the advantages of small and exquisite size, easy operation, accuracy and reliability. The core of the alignment device adopts a low-power consumption microcontroller to collect and control chips, and thus, the whole device is small and light. The collecting part of the alignment device is a special-purpose cable clamp, which can ensure that the special-purpose cable clamp is in contact with a reliable external insulating part and prevent interference between cable cores. A recognition program adopts a PIC microcontroller technology, and the cable core can be recognized by using a frequency generating and collecting device. The alignment device can realize rapid and accurate recognition of multiple cable cores of a secondary cable. The power consumption of the alignment device is small; a rechargeable lithium battery is used as a power supply to avoid frequently charging or replacing a battery, and thus, the trouble of replacing a battery and charging can be solved.

Owner:STATE GRID CORP OF CHINA +3

Integral locomotive air conditioner

InactiveCN100484790CConducive to miniaturization designThe whole machine is compactAir-treating devicesRailway heating/coolingAir cycleEngineering

The integral locomotive air conditioner is installed integrally in the top of locomotive via installing angles and includes indoor set and outdoor set in parallel inside one integral casing. Most of the pipe parts are inside the outdoor set to reduce noise and the interference on the inside. The integral locomotive air conditioner includes one casing, one indoor set, one outdoor set, installing angles, one indoor set wind scooper, one air intake grate connecting the air inlet of the indoor set and the top of the locomotive, and one air outlet grate connecting the air outlet of the indoor set and the top of the locomotive.

Owner:SHANDONG LONGERTEK TECH CO LTD

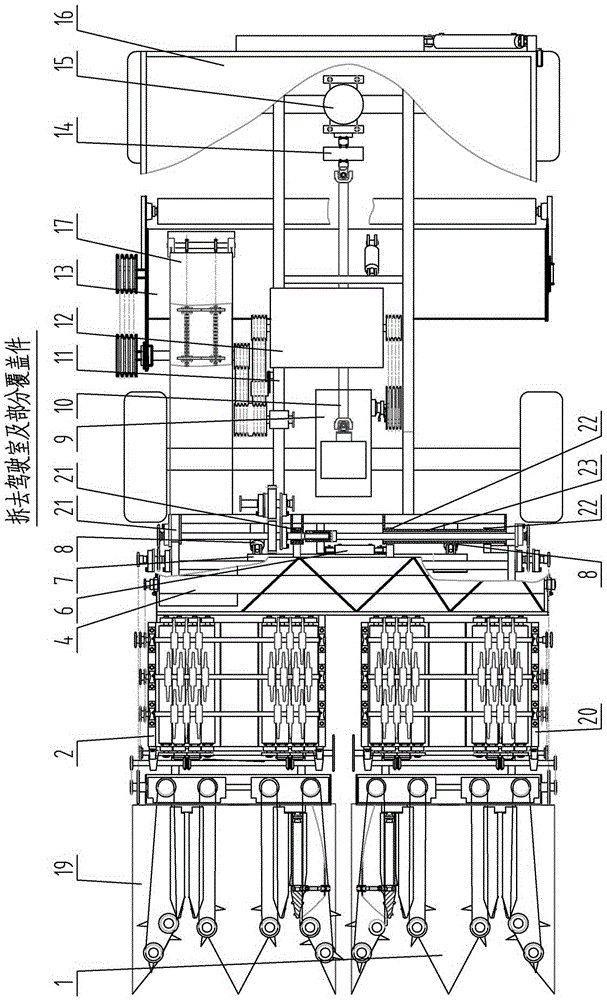

A four-row corn harvester with adjustable row spacing

InactiveCN104996077BSimple designThe whole machine is compactHarvestersEngineeringMechanical engineering

A four-line corn harvesting machine with adjustable line spacing is provided. A first peeling machine is assembled in the middle of a fixed spike picking device; a packing auger is assembled at the rear part of the first peeling machine; the fixed spike picking device is assembled at the front part of a rack through a fixed spike picking device supporting arm sleeve; a spike picking platform hoisting support is assembled at the lower part of the fixed spike picking device and is connected with the rack through a spike picking platform hoisting oil cylinder; a second peeling machine is assembled in the middle of a movable spike picking device; the movable spike picking device is slidingly assembled on a rack fixing sleeve through a movable spike picking device supporting arm sleeve; the movable spike picking device is slidingly supported on the spike picking platform hoisting support; one end of a spike picking platform line spacing adjusting oil cylinder is connected with the movable spike picking device and the other end of the spike picking platform line spacing adjusting oil cylinder is connected with the rack; an engine is mounted on the middle rack of the whole machine, a cab is mounted in front of the rack, a cluster box is mounted on the rear side of the rack and a field returning machine is mounted below the rack; and a lift conveyer is mounted on the rack at the right side of the cab. With the adoption of the structure, the whole machine is small and has light weight, low gravity center and hugh in-field passing capability; and the spike picking platform can be adjusted and the adaptability is improved.

Owner:SHANDONG CHANGLIN AGRI SCI EQUIP

Double-row maize harvesting machine for turning and discharging maize on hydraulic side of grain tank

The invention aims to provide a double-row maize harvesting machine for turning and discharging maize on a hydraulic side of a grain tank. The machine has the structural characteristics that a cluster tank is installed in the middle of the whole machine and installed on a rack through a turn oil cylinder; a diesel engine is installed on the right side of the rack behind the cluster tank; a driver seat is installed on the rack on the left rear part of the whole machine; a rear axle guide wheel assembly is installed below the rack; a canopy is arranged above the driver seat; a travelling transmission gear is arranged in front of the cluster tank; drive wheels are installed on drive shafts on the two ends of the travelling transmission gear; a peeling rack is arranged above the travelling transmission gear; the front part of the peeling rack is fixedly connected with a cutting platform rack, installed in a straight groove on the front part of the rack through sliding blocks which are installed on fixed shafts on the two sides of the lower part of the cutting platform rack and installed on the rack through a cutting platform lift oil cylinder; the rear part of the peeling rack is assembled on the rack through a connecting rod; a cutting platform transmission case is installed on the rear part of the cutting platform rack; a stem pulling roller is installed on the front output end of the cutting platform transmission case; and a spike picking plate and a conveying chain are arranged above the stem pulling roller, and a hobbing cutter and a stationary cutter are installed below the stem pulling roller. By adopting the structure, the whole machine is small, light in weight and low in gravity center, and the use reliability, adaptability and working efficiency of the machine are increased.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

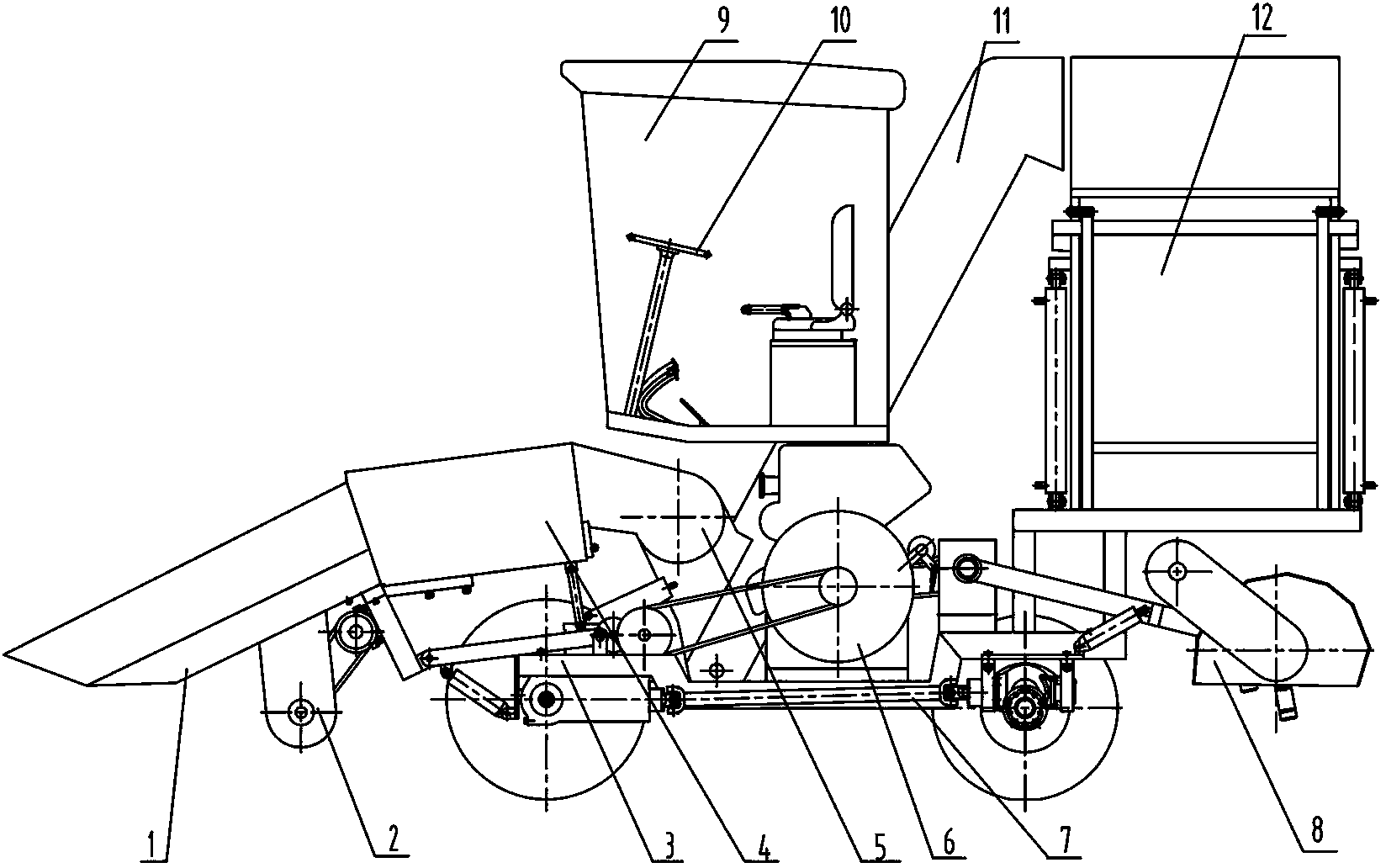

Miniature soybean combine harvester

The invention belongs to the field of agricultural machinery, and particularly discloses a miniature soybean combine harvester which comprises a machine frame, a power device assembly, a crawler walking device, a header assembly, a conveyor bridging device, a threshing and cleaning assembly, a water tank and a straw crushing device assembly. The miniature soybean combine harvester has the beneficial effects that the position and parts of the whole mechanism are regulated, so that the whole combine harvester is simple, compact, convenient to operate and high in harvesting efficiency; the combine harvester is slight in header vibration, and has a function of crushing straws for direct returning to the field, the ground clearance is smaller than 50mm, and the straws are sprayed and buried to be favorably decomposed and decayed; the combine harvester has functions of straw collection and the like, and is particularly designed for a soybean intercropping mode, the swath of a header is relatively narrow, and the harvesting speed is more than 6 to 7 acres per hour; the straws returned to the field are mixed with a mixed solution favorable for decomposition of the straws, so that the decomposition and decaying speed of the straws is increased; the harvesting productivity is as high as more than 6 to 7 acres per hour, the loss rate and the broken rate of soybeans are both not over 2 percent, and the cleaning rate of the soybeans is over 98 percent.

Owner:威海印九红果蔬种植专业合作社

A kind of automatic grain sorting equipment and automatic grain sorting method

InactiveCN103077914BImprove scalabilityShorten exchange timeSemiconductor/solid-state device manufacturingConveyor partsWaferProcess engineering

The invention discloses fully automatic crystal grain sorting equipment and a fully automatic crystal grain sorting method. The equipment consists of seven main parts including a wafer work table, a sorting work table, a transportation conveying system, a wafer work table propelling device, a sorting work table propelling device, a swinging arm mechanism and a chip sorting material cabin. The traditional layout and mechanical structure in the prior art is improved, an optimized layout structure is provided on a machine body platform, disc sheets can freely go in or out to be taken and placed among the work table, the propelling device and the chip sorting material cabin through the transportation conveying system, the fully automatic crystal grain sorting is realized, meanwhile, a transportation system has two buffer region positions, the exchange time between the disc sheets to be sorted and the disc sheets completing the sorting can be reduced, and further, the crystal grain sorting time and the crystal grain sorting efficiency are accelerated and improved. The equipment and the method have the characteristics that the sheet exchange is efficient, the whole machine is small and exquisite, the structure is compact, the whole machine stability is good, and the chip sorting material cabin has good expansion performance.

Owner:广东志成华科光电设备有限公司

A spraying machine

InactiveCN104533459BLower center of gravityImprove stabilityUnderground chambersTunnel liningShotcreteHydraulic cylinder

Owner:SHANDONG UNIV OF SCI & TECH

Electronic water heater

InactiveCN100424436CImprove performanceImprove energy efficiencyWater heatersInduction current sourcesFrequency conversionElectron

The invention relates to an electronic water heater, which comprises an power electronic frequency conversion magnetic inductive loop heating and plate type thermal interchange box. The invention realizes high thermal efficiency, easy production and low cost.

Owner:洪祥鹰

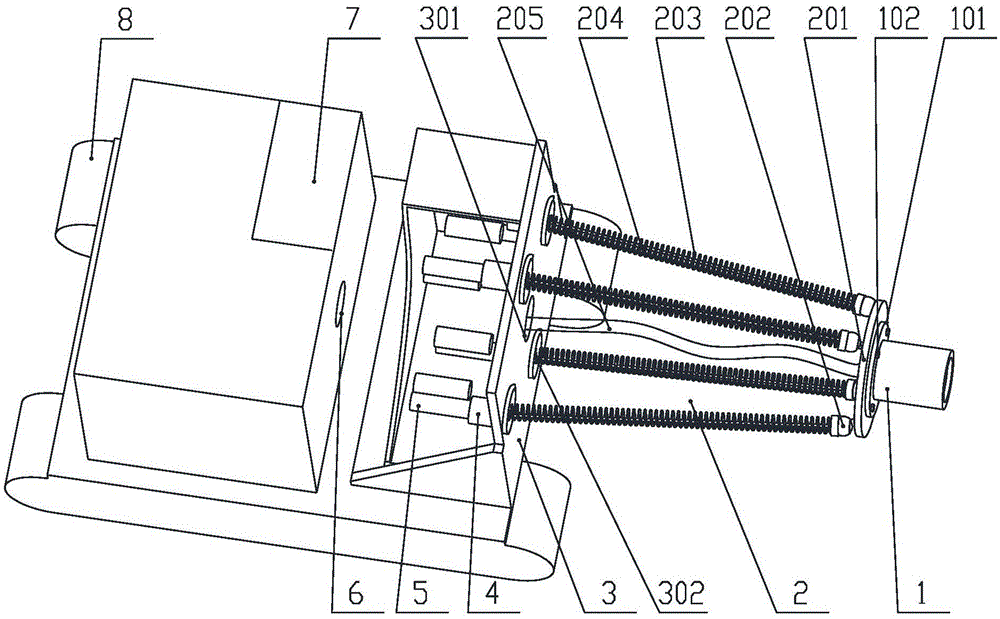

Flexible Vehicle Camera Steering Manipulator

The invention provides a steering mechanical hand for a flexible vehicle-mounted camera. The steering mechanical hand comprises a carrying trolley, a control cabinet and a base box. A control mechanism is arranged in the control cabinet, a power mechanism is arranged in the base box, a flexible steering mechanism is arranged between the base box and an installing disc of the camera and supplied with power by a power mechanism, and actions of the flexible steering mechanism are controlled through the control mechanism. The flexible steering mechanism comprises four springs and four pull ropes, one end of each spring is fixed to a corresponding spring fixing flange, the other end of each spring is connected to the installing disc through a spherical hinge device, the four pull ropes are arranged in the four springs respectively, each pull rope is parallel to the center line of the corresponding spring, one ends of the pull ropes are connected to a push rod of a worm gear reducer, and the other ends of the pull ropes are connected to the installing disc through the spherical hinge devices. The steering mechanical hand is convenient to install and maintain, large-angle detection can be achieved, and the application range of the flexible vehicle-mounted camera is greatly enlarged.

Owner:SHANDONG UNIV OF SCI & TECH

An electric remote control electrostatic adjustable profiling sprayer

ActiveCN104322472BReduce labor intensityImprove productivityInsect catchers and killersSteering wheelDrive wheel

The invention discloses an electric remote-control electrostatic adjustable profiling sprayer which comprises a rack and a power system, a steering system and a spraying system which are arranged on the rack. two driving wheels in the power system are used as rear wheels; two steering wheels in the steering system are used as front wheels; the spraying system comprises a water tank (1), a three-way valve (3), a water pipe (11), a water pump (14), a spraying rod (28), a spray nozzle (30) and a spraying rod regulating device; a four-edge movable rocker mechanism is formed by a left strut mechanism, a right strut mechanism, an upper guide block and a lower guide block; the steering system comprises a steering motor (21), a steering chain wheel (20), a guide plate (17), the steering wheels (19), a steering wheel connecting mechanism (36) and a steering mechanism. The electric remote-control electrostatic adjustable profiling sprayer is easy to implement, can be suitable for various environments, has good flexibility and has high spraying efficiency.

Owner:HUNAN AGRICULTURAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com