A kind of fertilizer grabbing soil covering machine

A soil-covering machine and soil-covering technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of low operation efficiency and fertilizer utilization rate, lack of orchard operation machinery and equipment, insufficient power and its own volume, etc., to ensure the effect of loosening soil. , enhance international competitiveness, the effect of compact machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

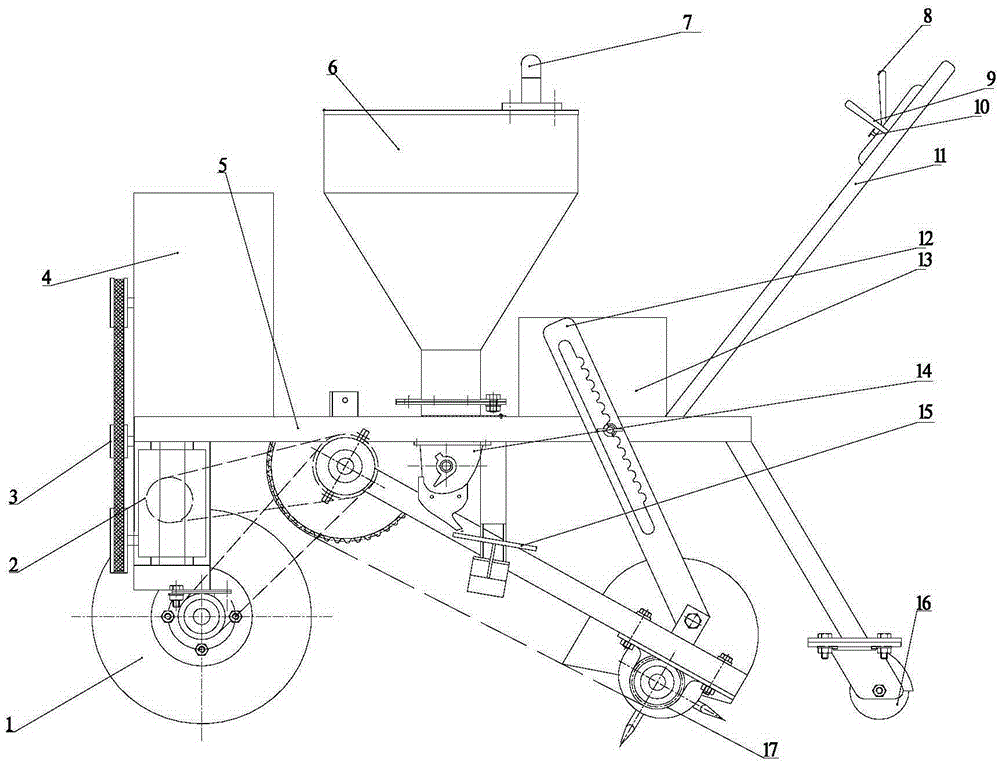

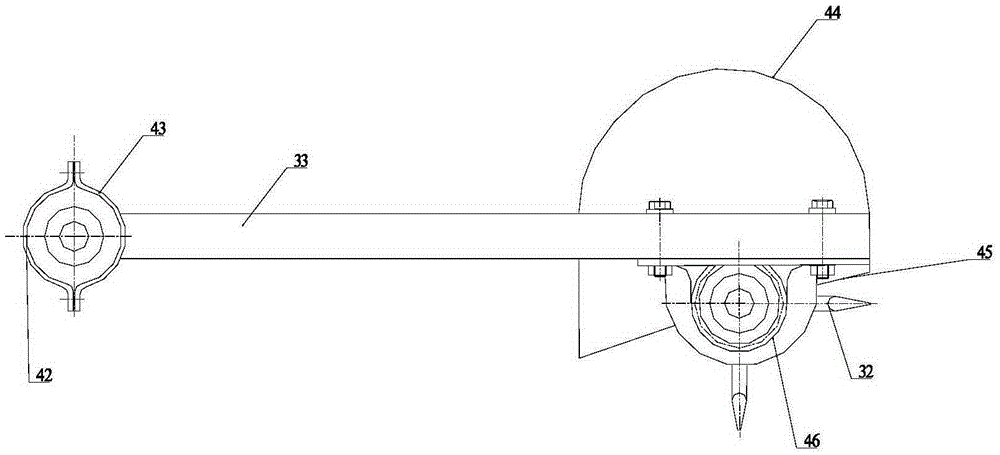

[0044] Such as Figure 1-12 , A fertilizing, soil-grasping and soil-covering machine, including a frame 5 and a driving and walking system, a transmission system, a fertilizing system, a soil-grabbing and soil-covering system and a control system set on the frame;

[0045] The driving and walking system includes a gasoline engine 4, a driving wheel 1 and a universal rear wheel 16 installed on the frame; there are two driving wheels, located at the front end of the frame; the universal rear wheel is set at the rear end of the frame;

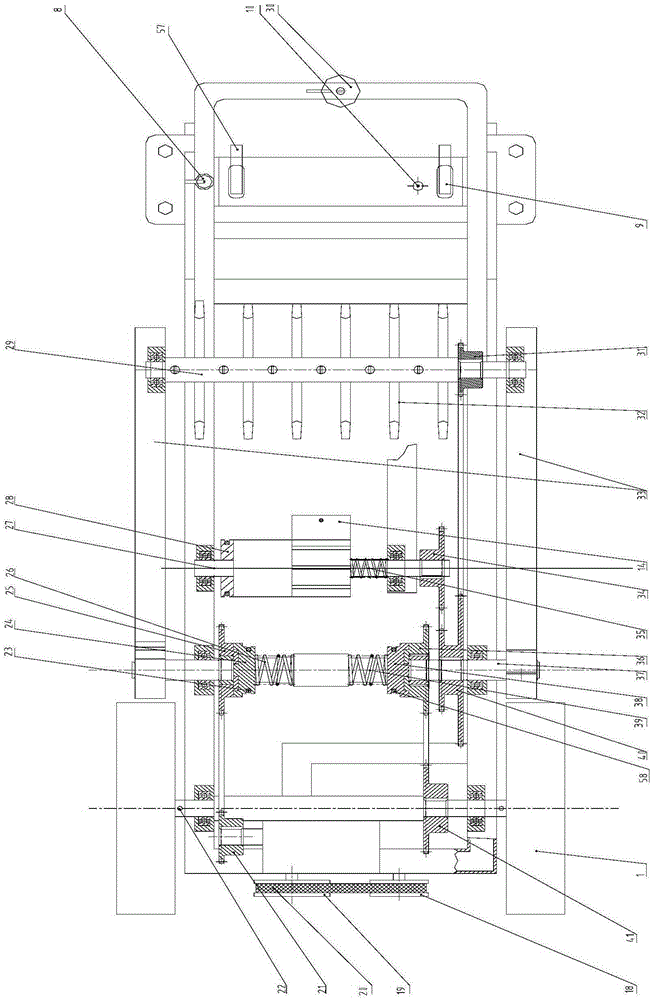

[0046] The transmission system includes a reducer 2, a power output gear 21, a tensioning wheel 3, a first jaw clutch 24, a traveling drive gear 36, a main shaft 37, a main shaft gear 25, a traveling shaft, a traveling shaft gear 41, and a second jaw clutch. The clutch 38, the double transmission gear 40 and the loosening shaft gear 31; the power wheel 19 of the gasoline engine, the tensioning wheel and the reducer pulley 18 of the reducer are driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com