Integral locomotive air conditioner

A locomotive air-conditioning, integrated technology, applied in the direction of vehicle parts, air handling equipment, railway car body parts, etc., can solve the problems of miniaturized design of locomotives that limit the installation of air-conditioning, unfavorable passenger rest, short service life, etc., and achieve complete ventilation. The effect of good heat dissipation, reduced interference, and shortened system distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

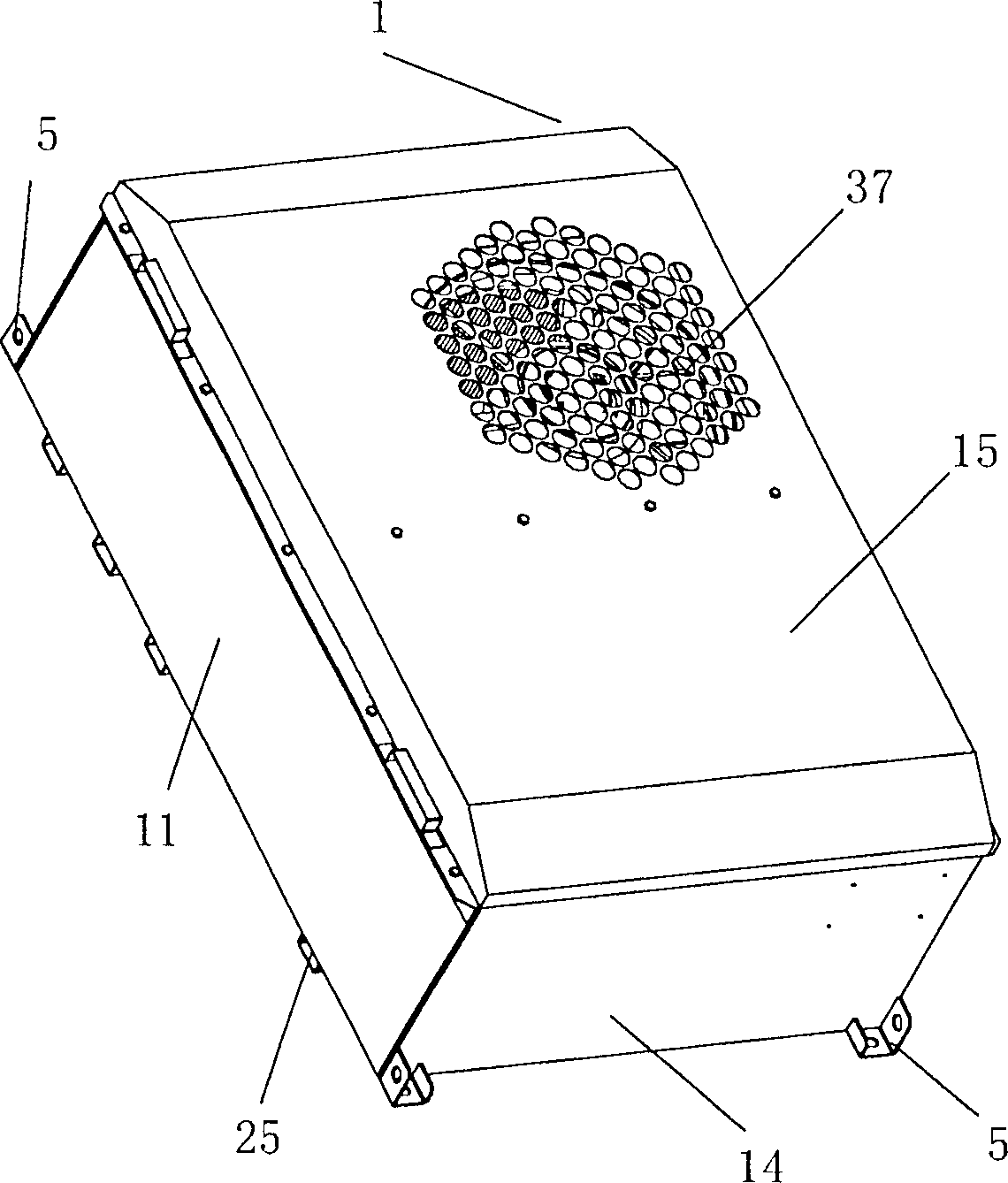

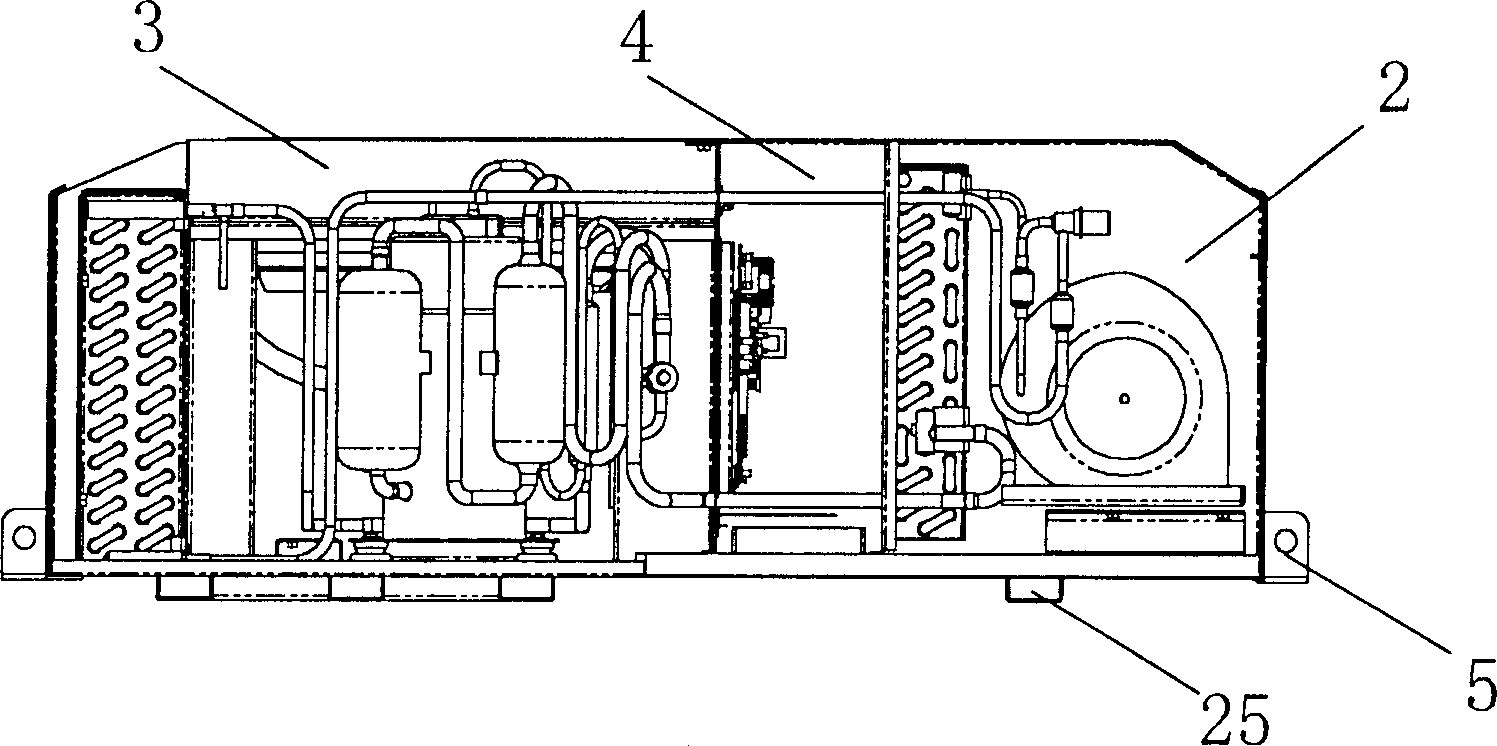

[0049] Example 1, such as Figure 1 to Figure 13 As shown, the integrated locomotive air conditioner is integrally installed on the outer roof 7 of the locomotive, the indoor unit 2 is connected to the inner roof 8 of the locomotive through the air guide cover 6, and the whole unit is connected to the outer roof 7 of the locomotive through the installation angle 5.

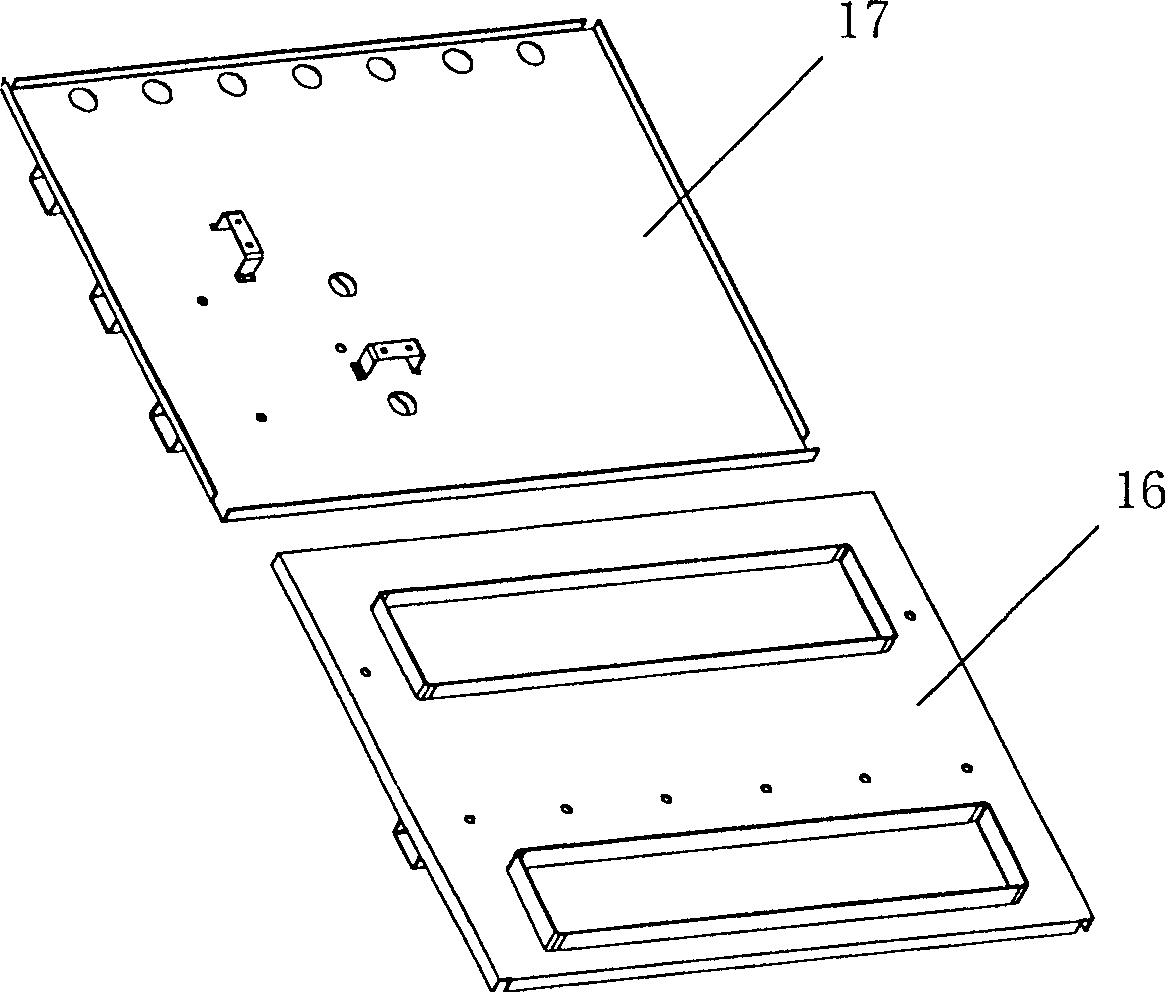

[0050] Described integrated locomotive air conditioner, its shell 1 is made up of front side plate 11, rear side plate 12, left side plate 13, right side plate 14, top plate 15 and indoor unit base plate 16, outdoor unit base plate 17.

[0051] Its indoor unit 2 has, indoor air inlet 21, indoor air outlet 22, indoor fan 23, and be positioned at indoor air inlet 21 side, and the indoor evaporator 24 that is installed on the mounting plate 241, and indoor unit drainage groove 25 is lower than indoor. Machine bottom plate 16.

[0052]Its outdoor unit 3 has, compressor 31, outdoor blower fan 32, outdoor condenser 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com