Machine with holding type collateral twisting mechanism for testing cocoon quality

A quality testing and clamping technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of complex structure, difficult maintenance and large occupied area of the winding mechanism, and achieve simple structure, not easy to malfunction, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

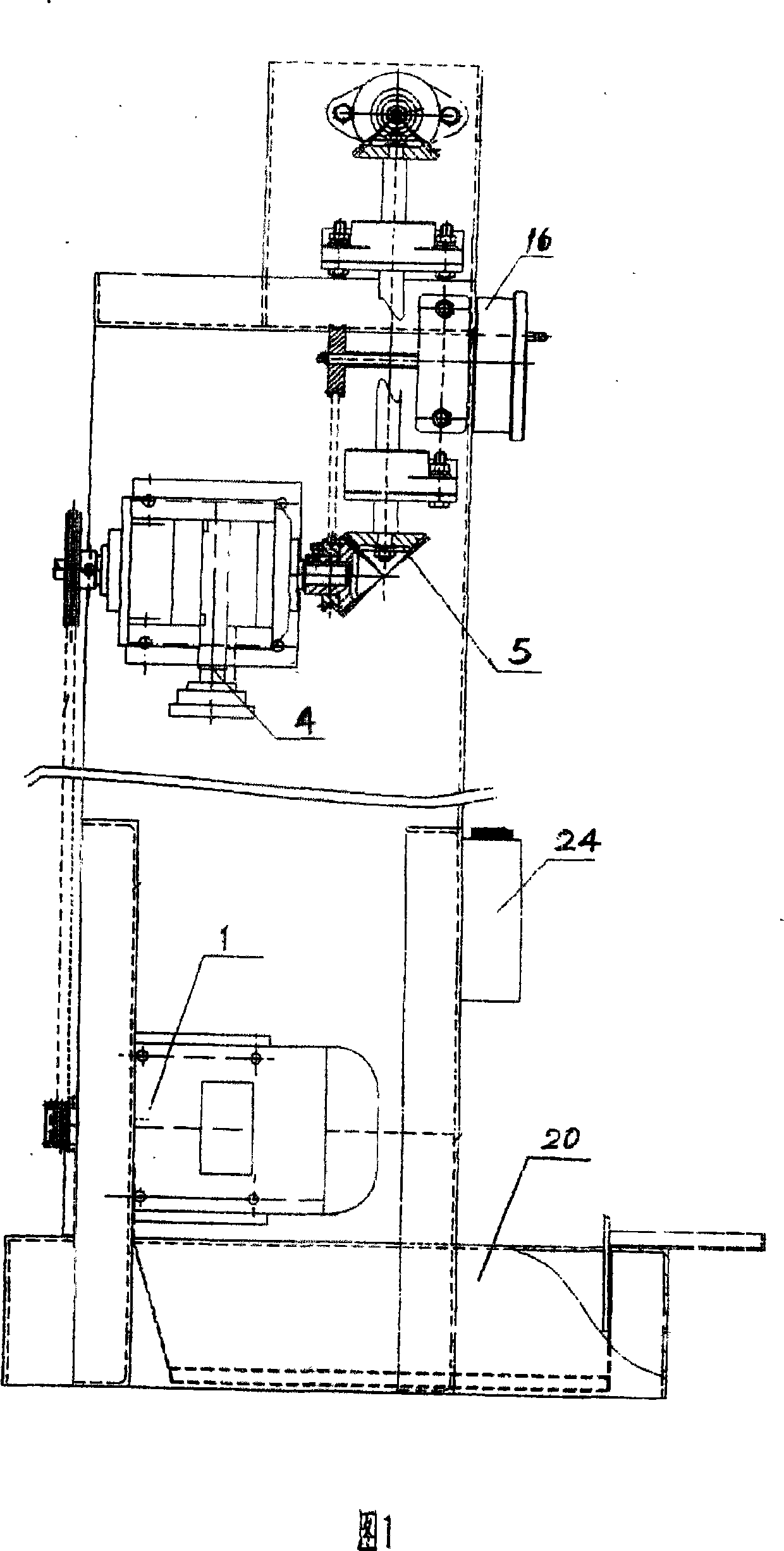

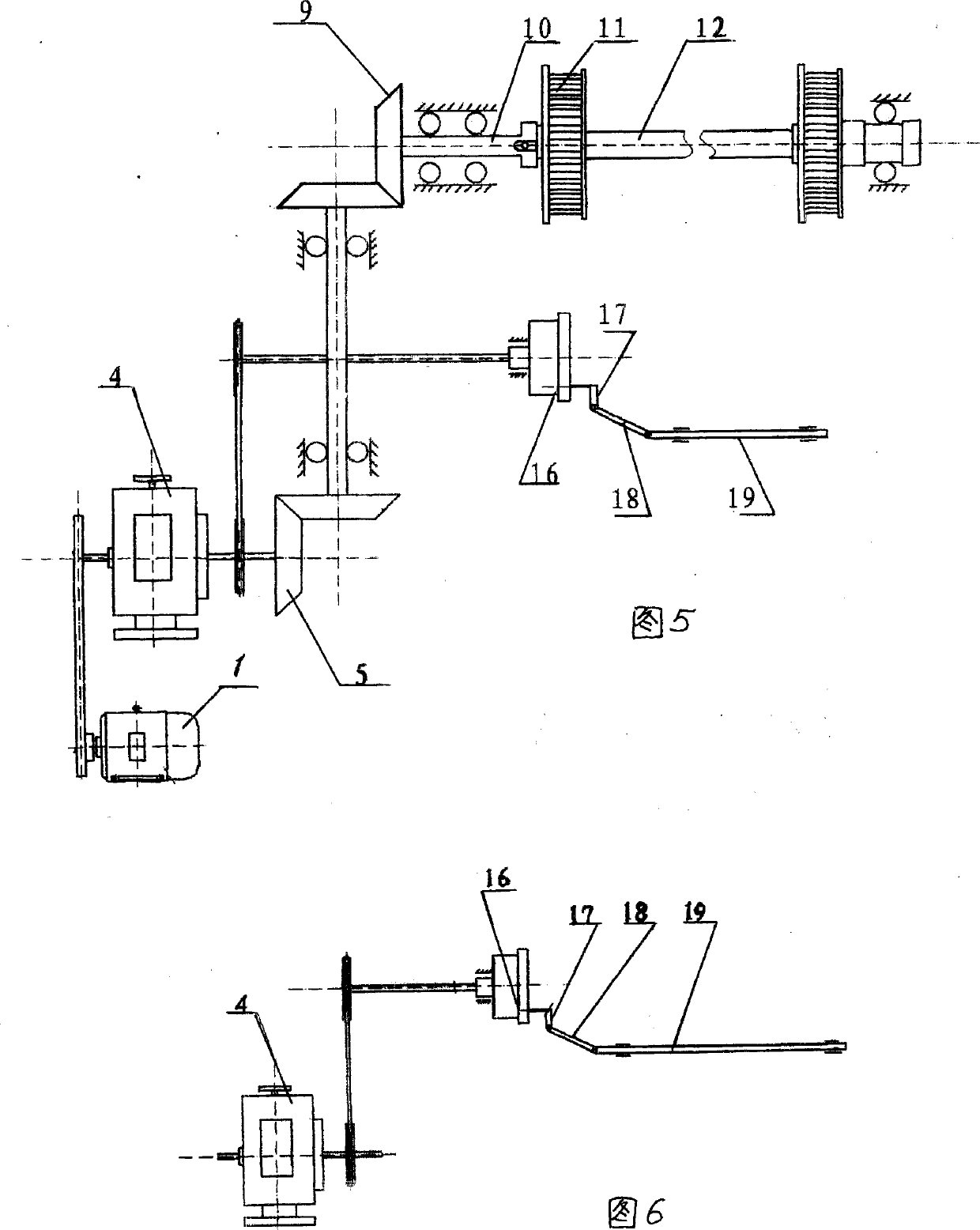

[0024] The silkworm cocoon quality testing machine with a clamping winding mechanism includes a power rotating part, a silk reeling part, and a recorder 24 for the number of falling threads. of multiple bevel gears 5 and with small The end bevel gear 9 connected to the transmission shaft 10, the small drive shaft 10 with Axis 12 connection, The same rotation axis on the shaft 12 is provided with five small 11. These five small 11 are identical in size and with the rotating shaft; the bevel gear 5 links to each other with the winding mechanism 16, and the winding mechanism 16 links to each other with the winding reciprocating rod 19 via the winding output shaft 17 and the winding connecting rod 18, and the winding reciprocating rod 19 is parallel to Axle 12; On the upper frame of silk reeling machine, five small speed sensor, each small 11 is embedded with a small magnetic steel, small The rotating speed sensor is the same as the number of small magnetic steels...

specific Embodiment 2

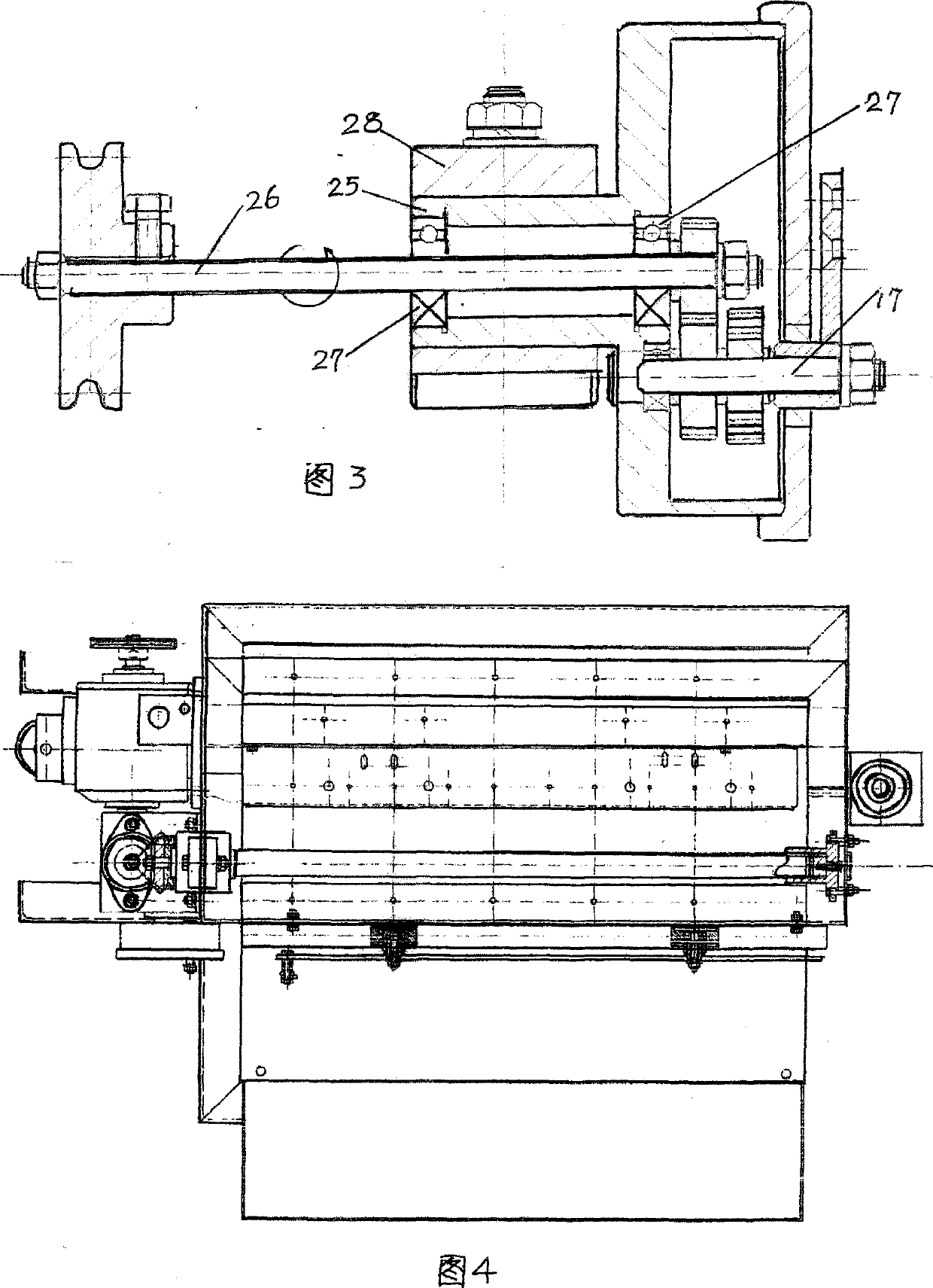

[0025] A reversing gear 29 is arranged between the twisting input shaft 26 and the twisting output shaft 17, so that the twisting input shaft 26 and the twisting output shaft 17 can rotate in the same direction with different central axes. Other structures are all the same as in specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com