A kind of automatic grain sorting equipment and automatic grain sorting method

A fully automatic and sorting technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low efficiency, transmission speed affecting the overall performance of the machine, and inability to meet the needs of use, to speed up time and efficiency. , The stability of the whole machine is good, and the effect of reducing the exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

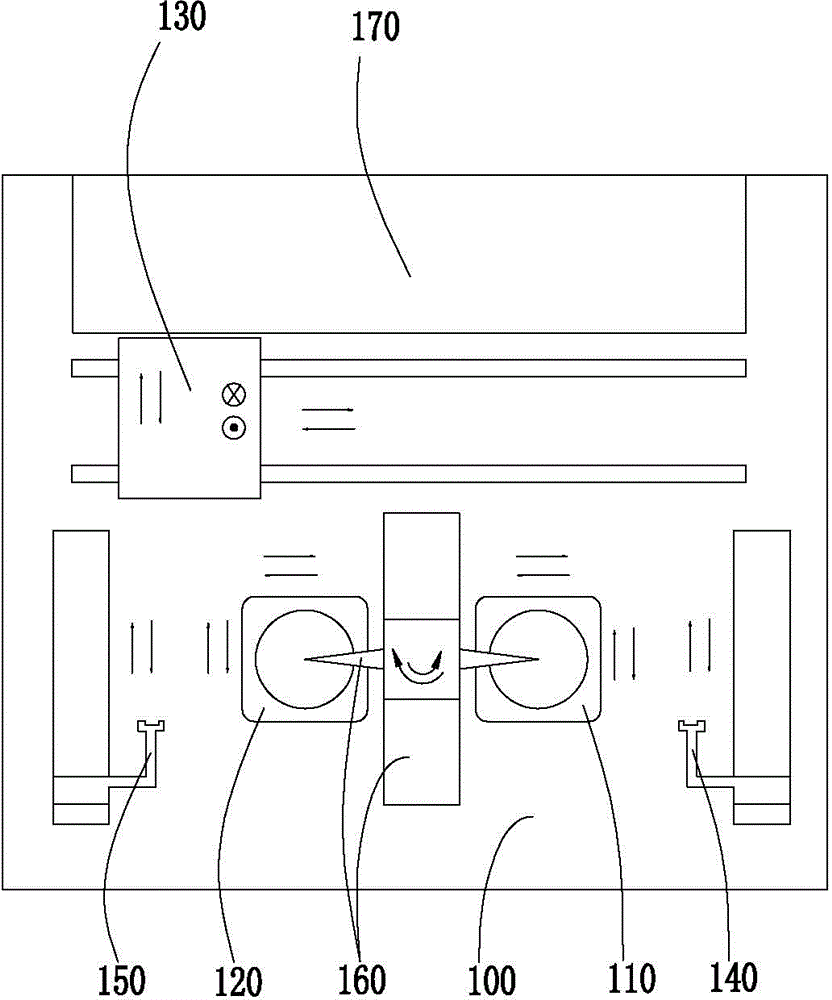

[0061] One of the specific implementations of a fully automatic grain sorting device of the present invention includes an organism platform 100, and the organism platform 100 is provided with:

[0062] Two workbenches, respectively a wafer workbench 110 and a sorting workbench 120, which are used to carry discs;

[0063] Swing arm mechanism 160, through which the wafer discs on the wafer workbench 110 and the sorting discs on the sorting workbench 120 are sorted;

[0064] Chip sorting material library 170, which is used to store chip sorting cassettes and chip wafer cassettes, wherein the chip sorting cassettes are used to store sorting discs, and the chip wafer cassettes are used to store wafers. Disc;

[0065] The transport conveyor system 130, which can move along the X-axis, Y-axis and Z-axis directions, the transport conveyor system 130 has two buffer positions, and the transport conveyor system 130 corresponds to Take out the discs to be sorted and place them in the fi...

Embodiment 2

[0073] The second specific embodiment of a fully automatic grain sorting device of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, No further details will be given here.

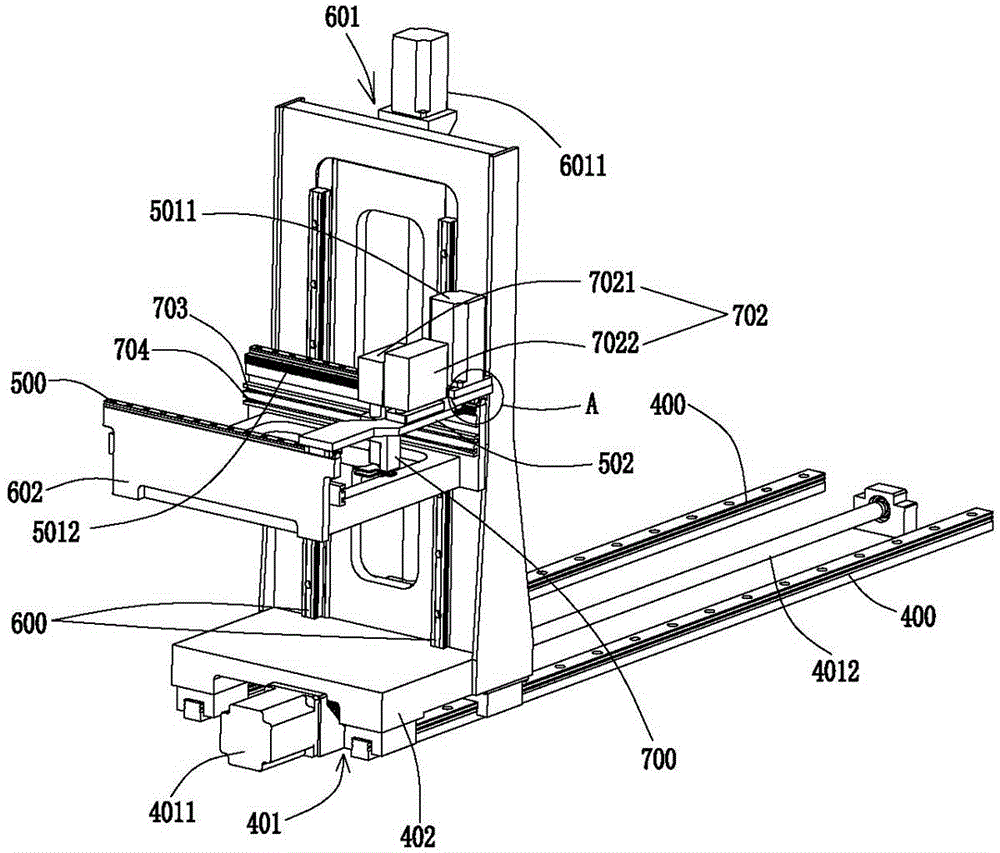

[0074] The difference between this embodiment and Embodiment 1 is that the transportation delivery system 130 includes:

[0075] An X-axis guide rail 400, an X-axis base 402, and an X-axis driving device 401 that drives the X-axis base 402 to reciprocate along the X-axis guide rail 400;

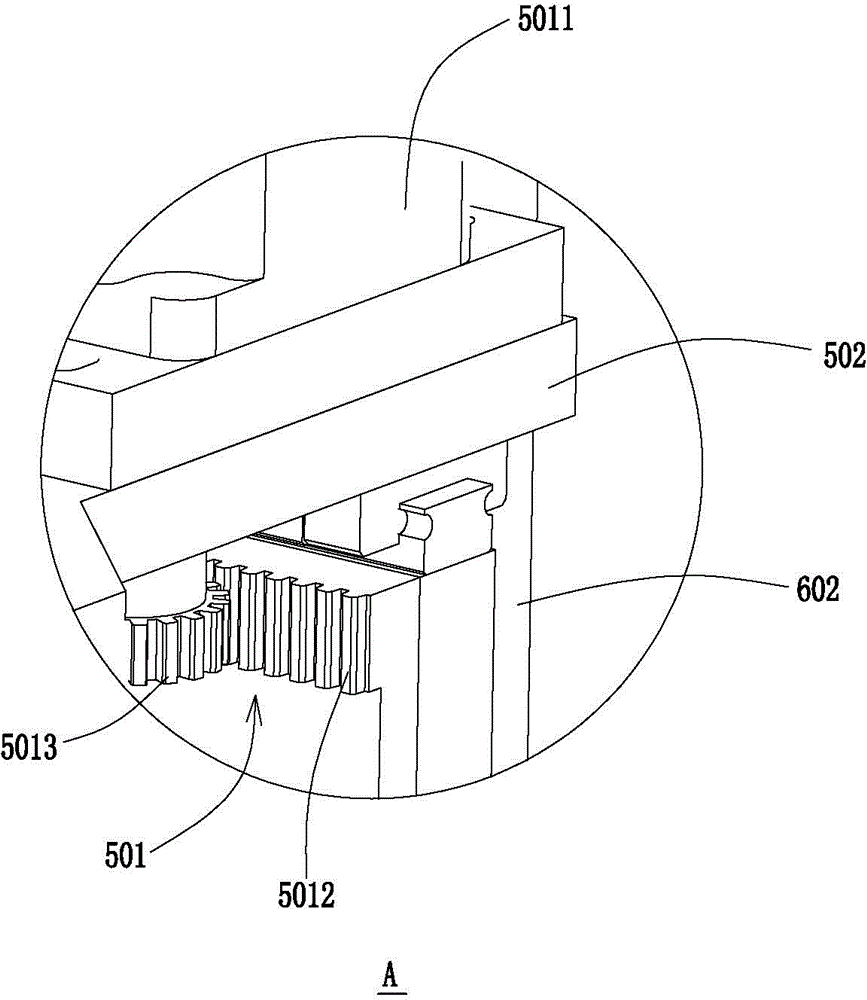

[0076] A Y-axis guide rail 500, a Y-axis base 502, and a Y-axis drive device 501 that drives the Y-axis base 502 to reciprocate along the Y-axis guide rail 500;

[0077] The Z-axis guide rail 600, the Z-axis base 602, and the Z-axis driving device 601 that drives the Z-axis base 602 to reciprocate along the Z-axis guide rail 600, and the Z-axis guide rail 600 is fixedly arrange...

Embodiment 3

[0084] The third specific embodiment of a fully automatic grain sorting device of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, No further details will be given here.

[0085] The difference between this embodiment and Embodiment 1 is that the push device includes:

[0086] fixed bracket 1;

[0087] The transfer driving device 2 is used to transfer the transferred disk from the workbench to the transport delivery system 130 or back to the workbench from the transport delivery system 130. The transfer drive device 2 includes a The mounting seat 21, the transfer screw 22 arranged on the mounting seat 21, the motor driving the transfer screw 22 to rotate, and the sliding seat 23 screwed to the transfer screw 22;

[0088] Clamp mechanism 4, which is used to clamp the disc or loosen the disc, the clamp mechanism 4 composed of upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com