Double-row maize harvesting machine for turning and discharging maize on hydraulic side of grain tank

A corn harvester and hydraulic technology, applied in the field of machinery, can solve the problems of poor passing performance in the field, poor passing performance, and failure to satisfy users, etc., and achieve improved reliability and adaptability, flexible and easy operation, and ear picking performance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

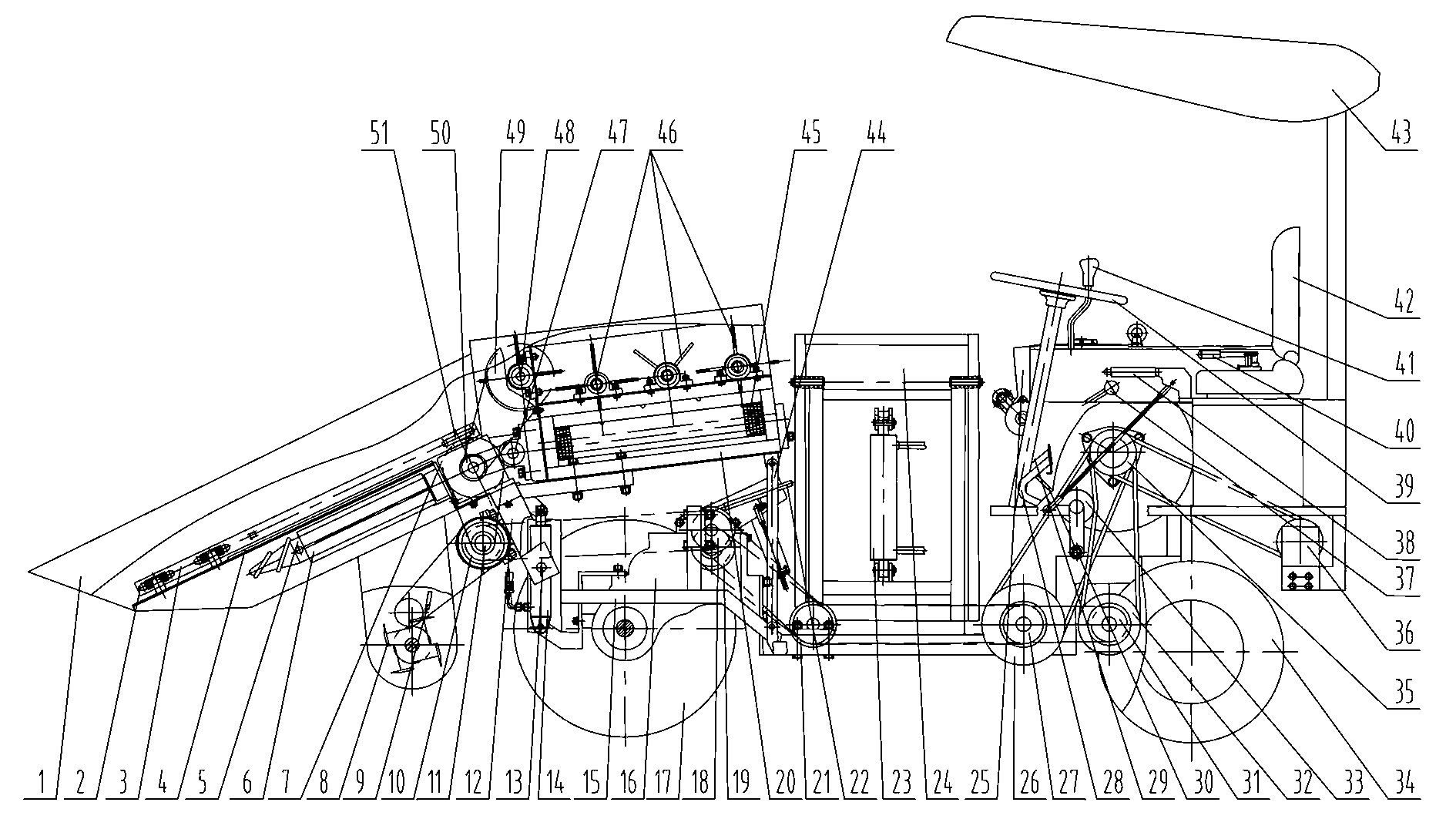

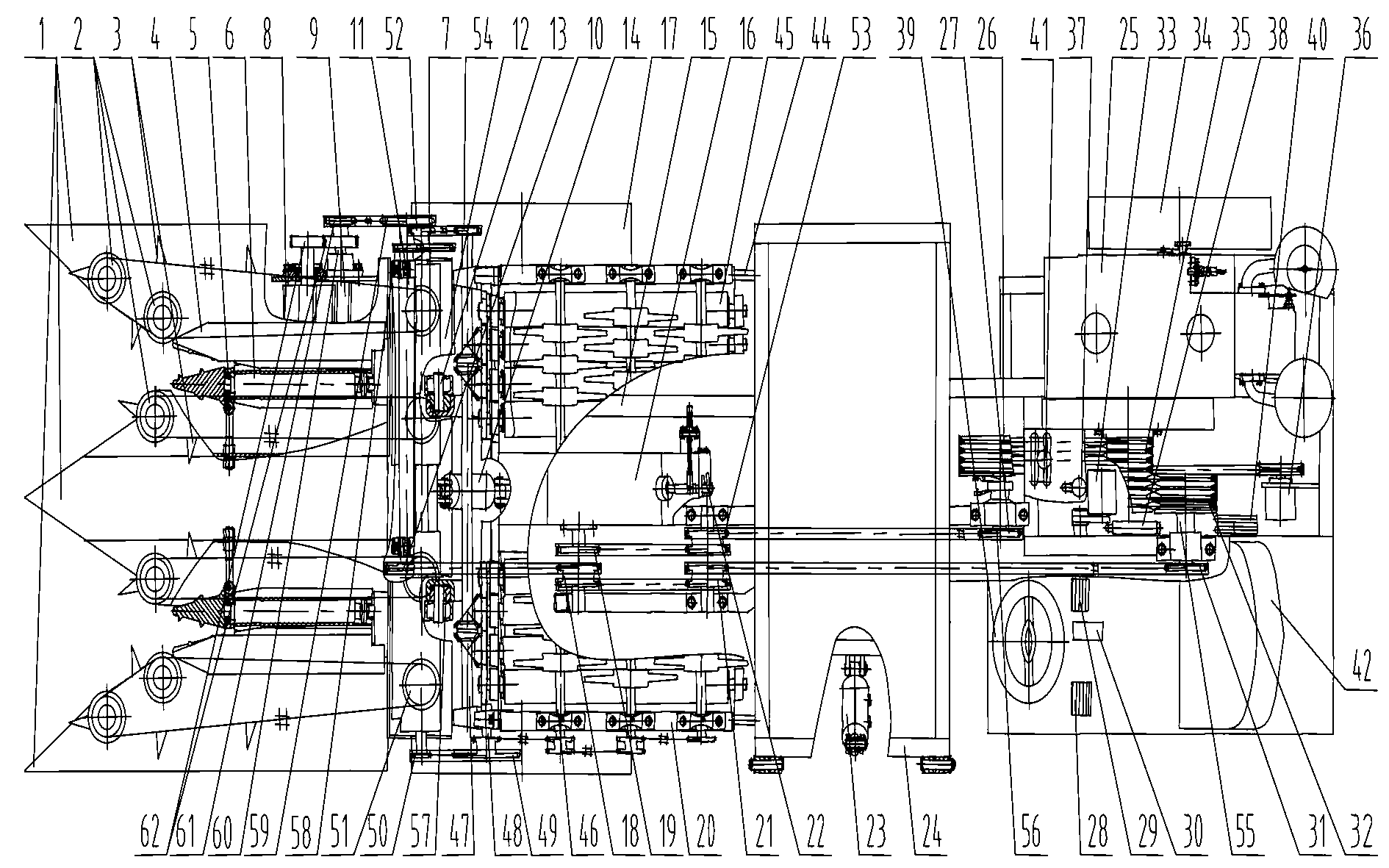

[0010] Attached below figure 1 , attached figure 2Further description is given to the specific implementation of a double-row corn harvester with hydraulic rollover and unloading in the grain tank of the patent of the present invention: start the diesel engine (25), and the power of the diesel engine (25) is installed on the pulley (35) of the diesel engine One way of the V-belt is transmitted to the oil pump (36), which drives the oil pump (36) to work and outputs high-pressure oil to provide power for the hydraulic system; the other way is transmitted to the travel clutch (26), and the travel clutch (26) is separated by the clutch pedal (28) When combined, the clutch shaft (56) drives the clutch shaft driving sprocket (27) installed on its left end to rotate, and the power is transmitted to the intermediate wheel (53) through the chain, and the intermediate wheel (53) transmits the power to the intermediate wheel (53) through the chain. The gearbox input sprocket (19) prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com