Dry ice spraying device and dry ice spraying method

A technology of spraying device and dry ice, applied in spraying device, liquid spraying device, etc., can solve the problems of difficulty in continuous supply of dry ice particles, easy blockage of dry ice particle transportation, delay in cleaning work, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

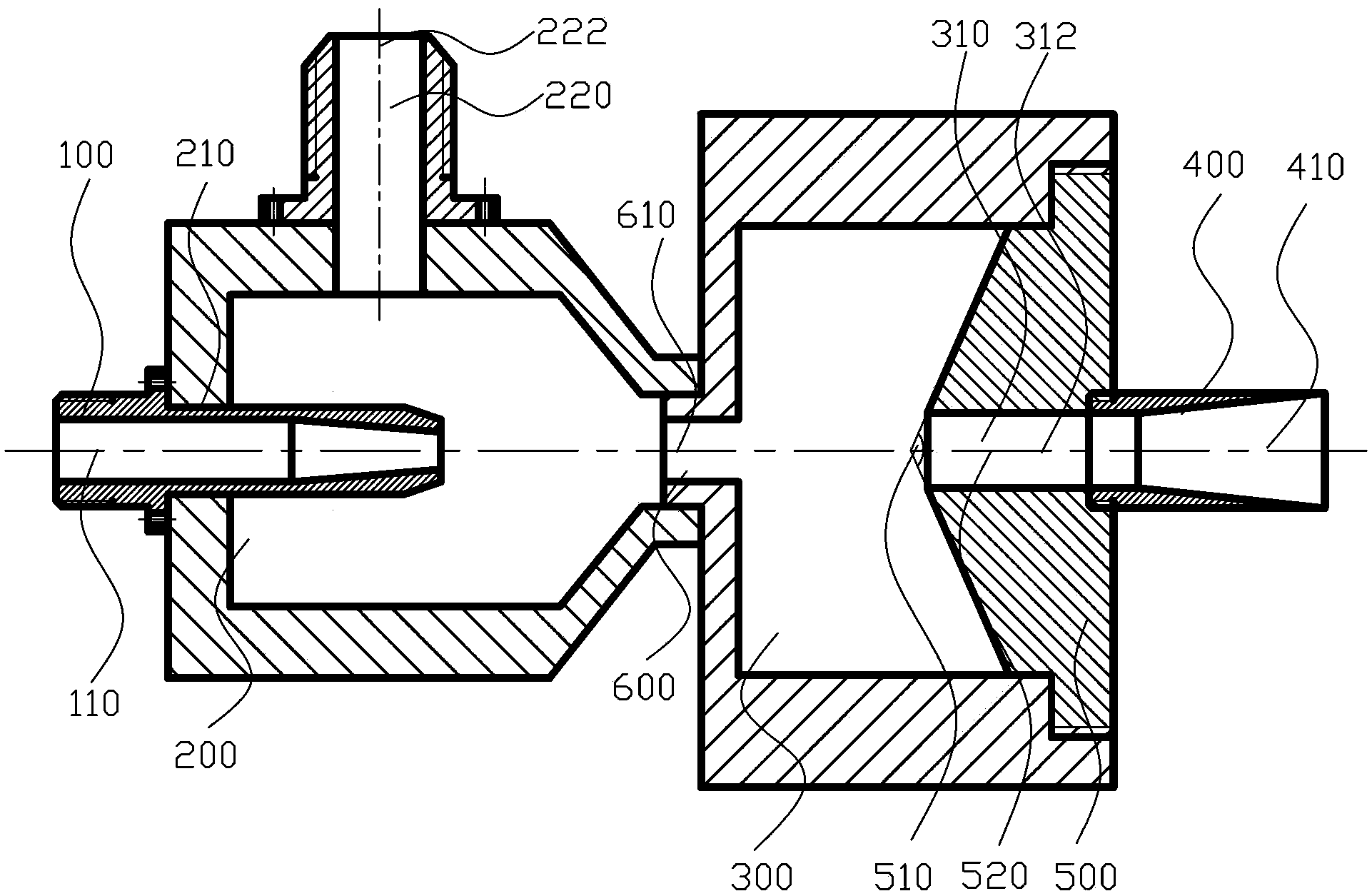

[0020] Such as figure 1 As shown, a dry ice blasting device includes a compressed air nozzle 100, a mixing chamber 200, an oscillation chamber 300, a diffuser pipe 400, and a collision wall 500. The mixing chamber 200 is provided with an installation through hole 210 and a dry ice inlet 220. The compressed air nozzle 100 is embedded in the installation through hole 210, the mixing chamber 200 communicates with the oscillation chamber 300 through the dry ice injection channel 600, the oscillation chamber 300 is provided with a dry ice outlet 310, and the diffusion pipe 400 is installed on the dry ice At the outlet 310 , the collision wall 500 is disposed in the oscillation chamber 300 and is opposite to the dry ice injection channel 600 . The compressed air nozzle 100 is used to be connected with an air delivery pipeline so as to inject compressed air. A dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com