Rotary extrusion precision drawing machine

A drawing machine and precise technology, applied in the field of precision drawing machines for pipes, can solve problems such as inability to draw pipes, and achieve the effects of easy disassembly or replacement, wide processing range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

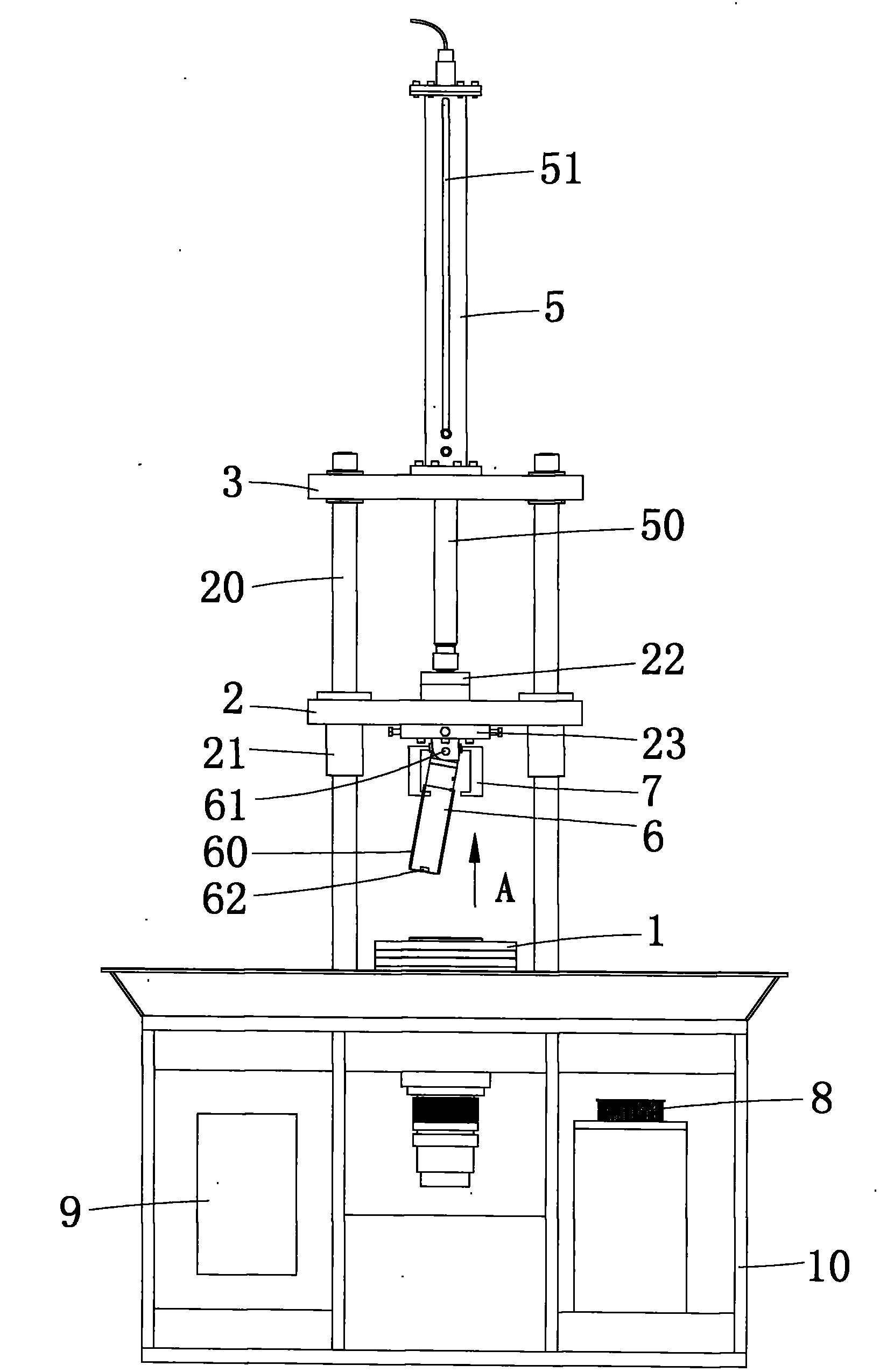

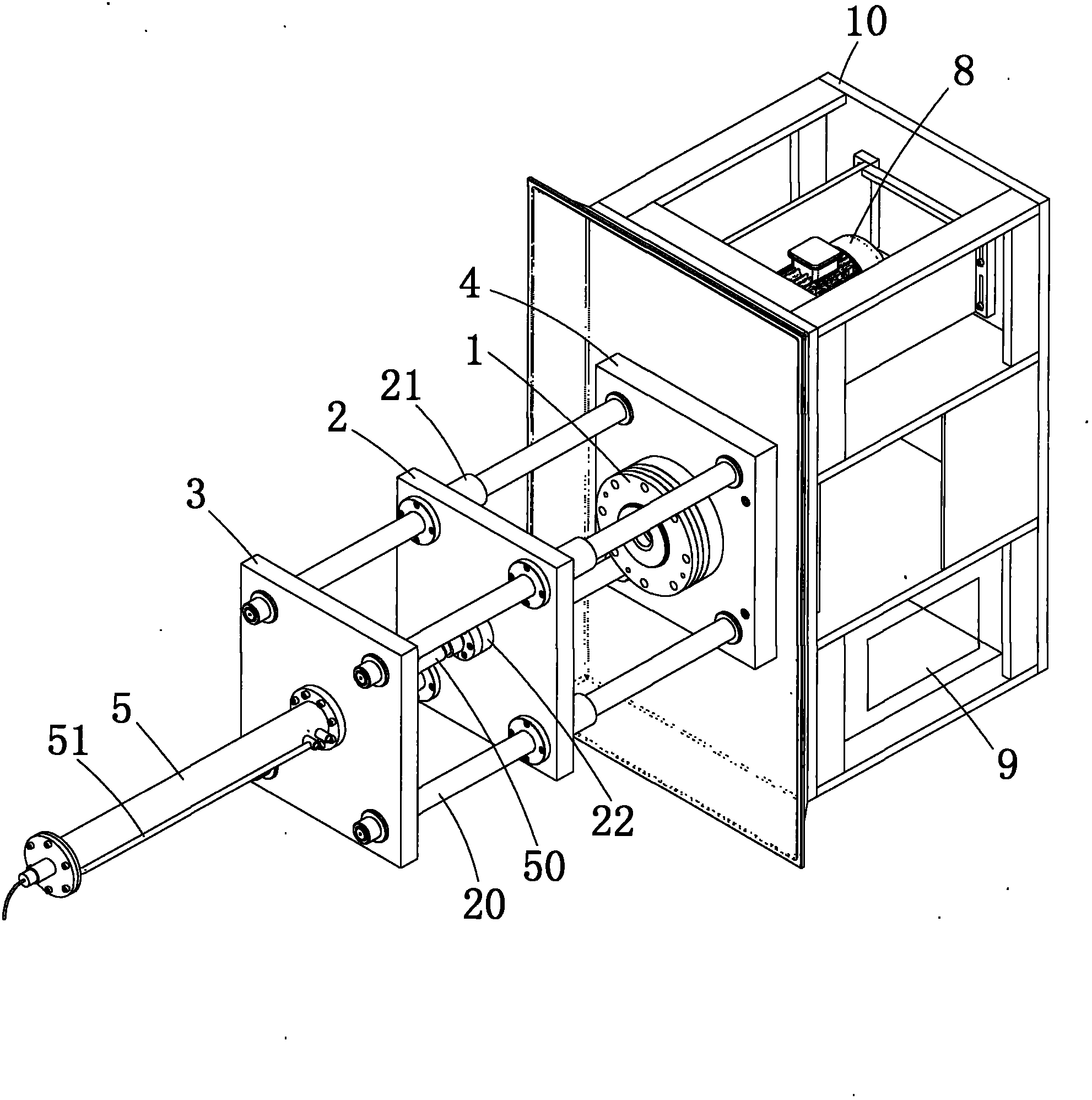

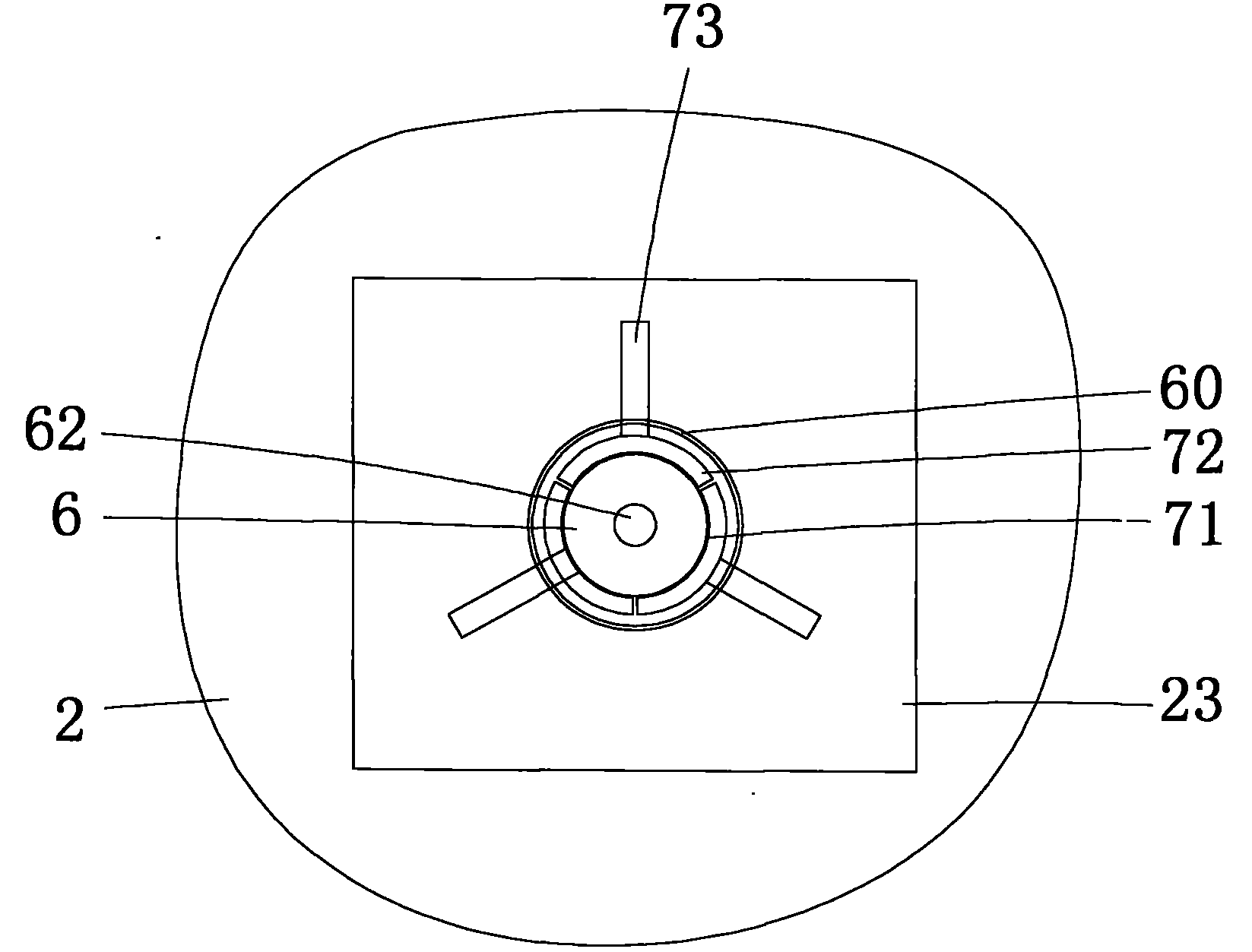

[0039] see figure 1 and figure 2 as shown, figure 1 It is a schematic diagram of the front view of the spinning precision stretching machine of the present invention in the working state, figure 2 It is an axonometric schematic diagram of the spinning precision drawing machine of the present invention. The spinning precision drawing machine includes a spinning head 1, a middle movable plate 2, at least two guide rails 20, at least two sliding guides 21, a hydraulic rod base 22, a mandrel base 23, a Top plate 3, a base plate 4, a hydraulic cylinder 5, a hydraulic rod 50, a lubricating device 51, a mandrel 6, a fixed pin 61, a coaxial sensor 62, a clamping device 7, a motor 8, a control Device 9 and a body 10.

[0040] The spinning precision stretching machine is based on the body 10 and can be divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com