Centering mechanism for adjusting eccentricity of reverse extrusion rod

A technology of reverse extrusion and center adjustment, which is applied in the field of reverse extrusion rod eccentric center adjustment mechanism, and achieves the effects of simple structure, reduced labor intensity, and convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

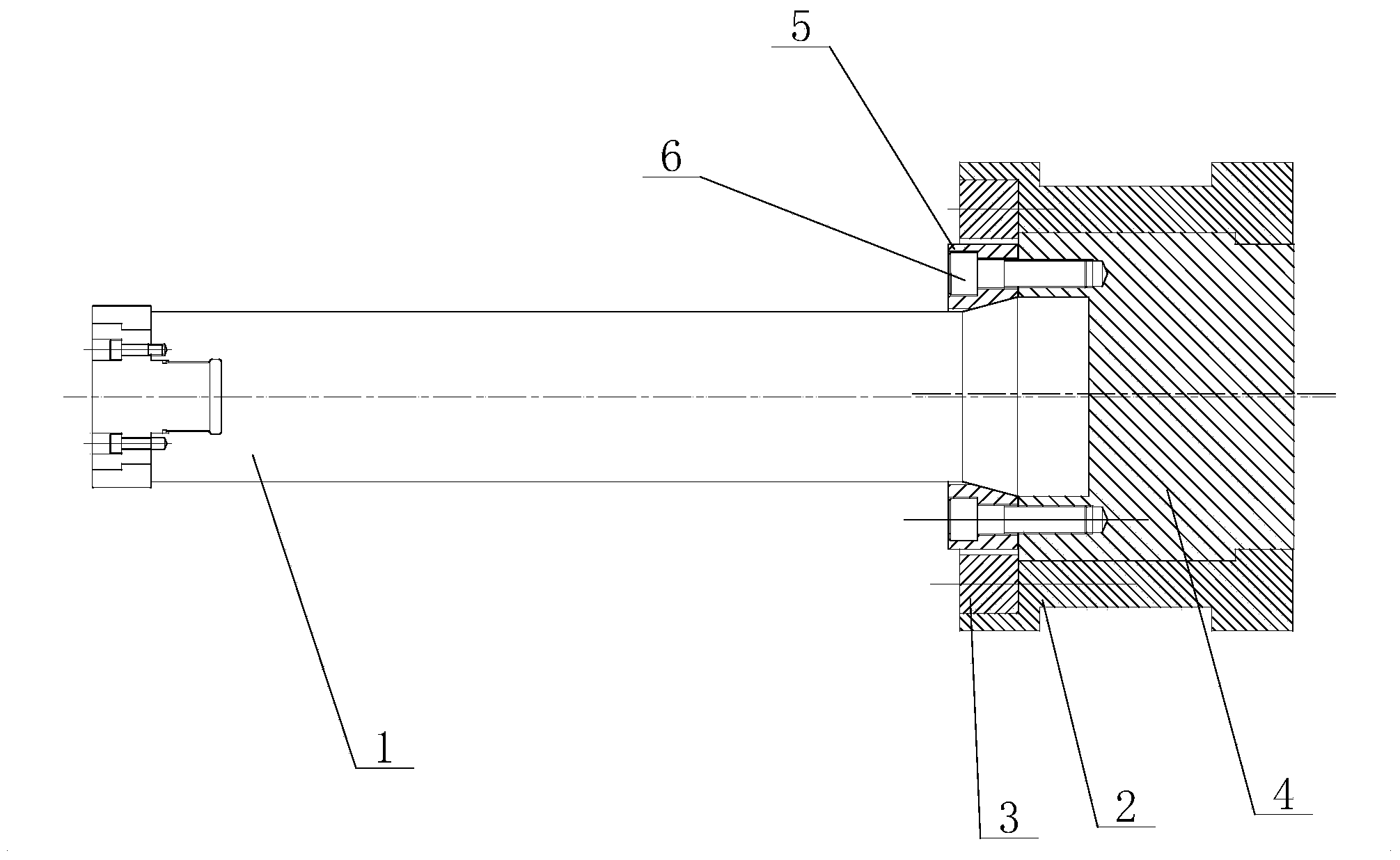

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0012] see figure 1 as shown, figure 1 It is a structural schematic diagram of the reverse extrusion rod eccentric centering mechanism provided in Embodiment 1 of the present invention.

[0013] In this embodiment, a reverse extrusion rod eccentric centering mechanism includes a reverse extrusion rod 1, and one end of the reverse extrusion rod 1 is provided with a mold moving slider 2, and inside the mold moving slider 2 The reverse extrusion rod support pad 4 is fixed by the reverse extrusion rod support pad pressure ring 3, and the reverse extrusion rod support pad 4 and the reverse extrusion rod 1 are eccentric structures whose centerlines are not on the same straight line. The reverse extrusion rod 1 is fixed on the reverse extrusion rod supporting pad 4 through the reverse extrusion rod press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com