Automatic butt-joint welder for panels of lock sets

A butt welding machine and panel technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of inconvenient operation, low work efficiency, unstable welding quality, etc., and achieve convenient operation, stable welding quality, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, a specific embodiment is provided below, and the present invention is further described in conjunction with the accompanying drawings.

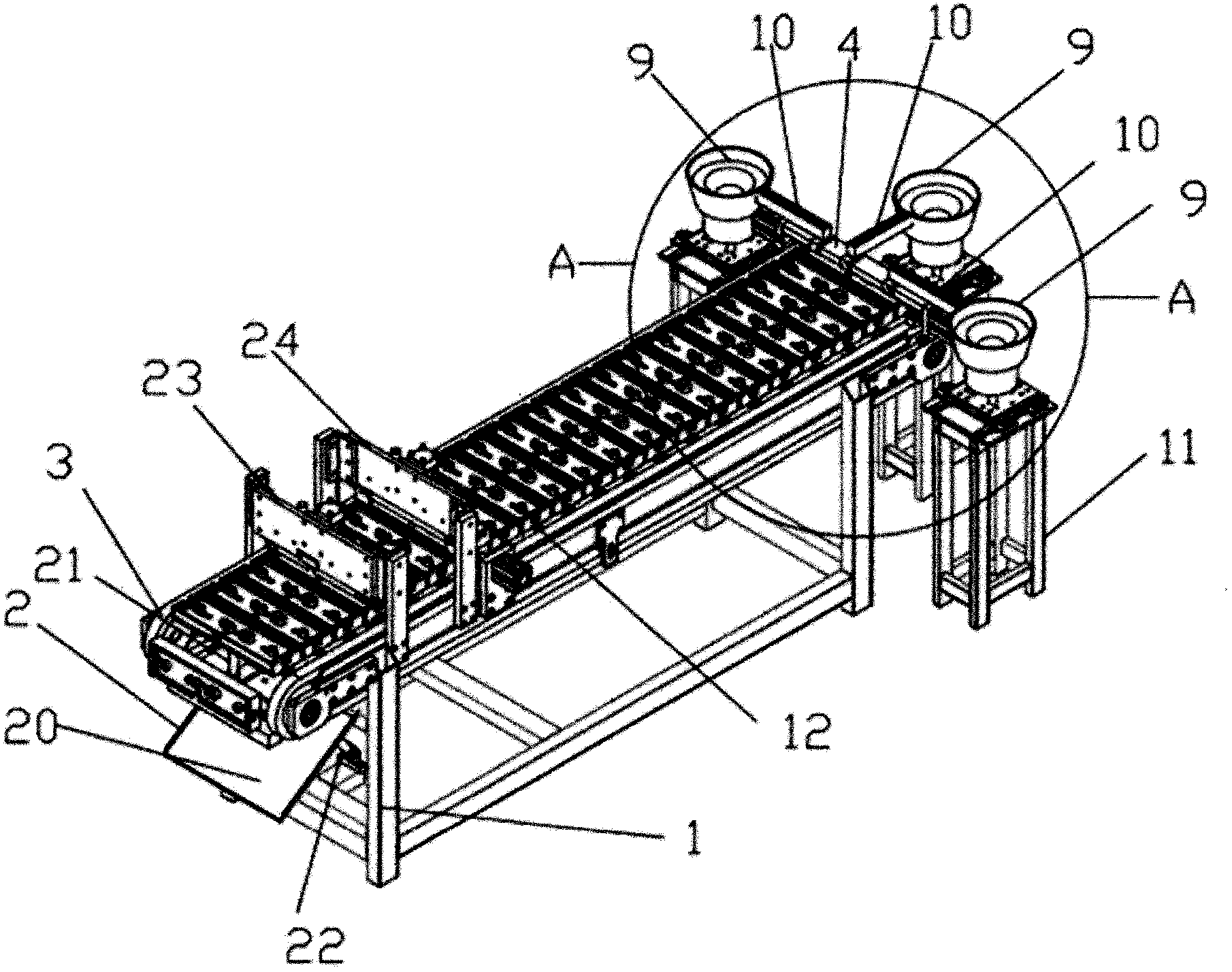

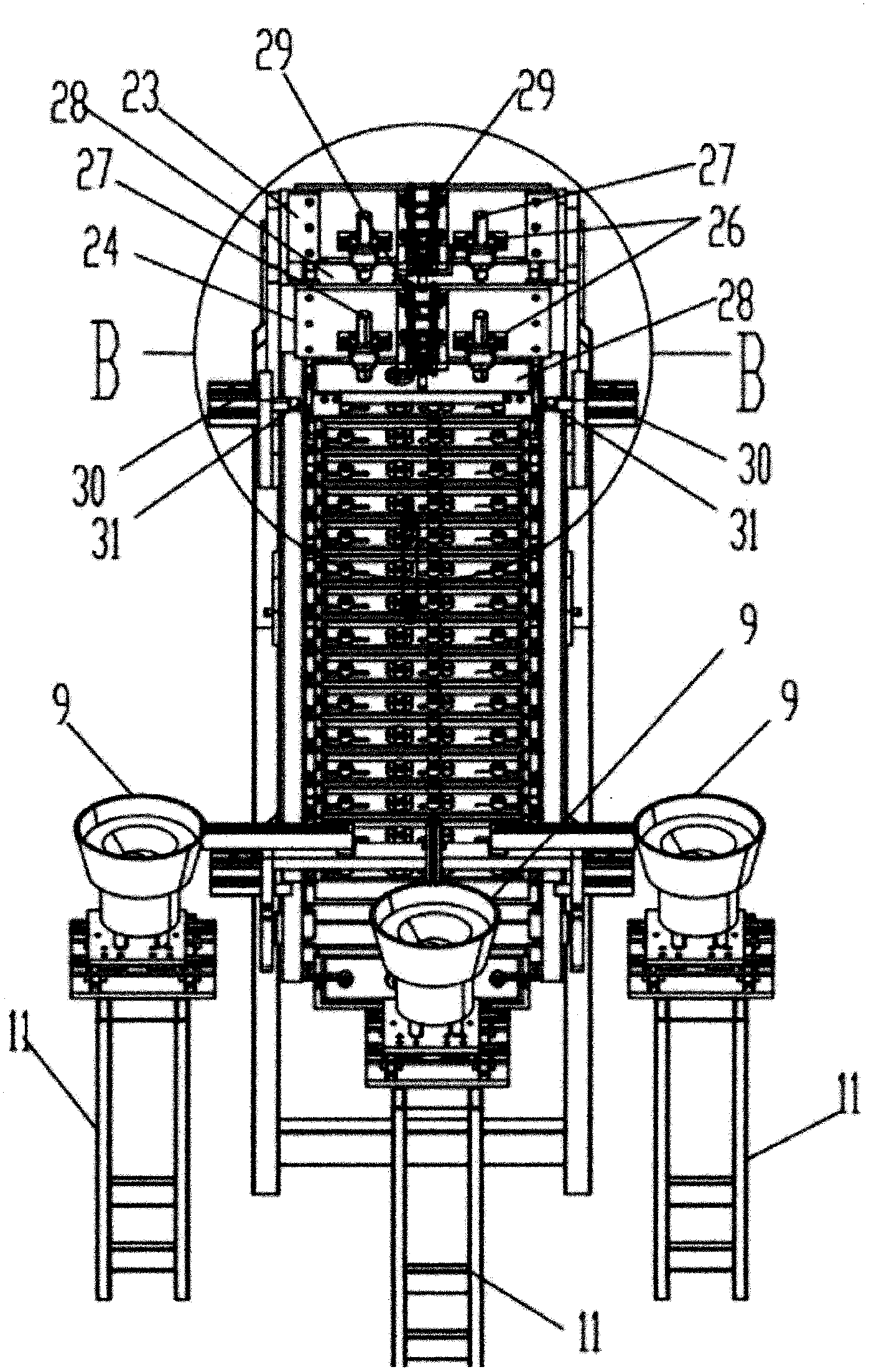

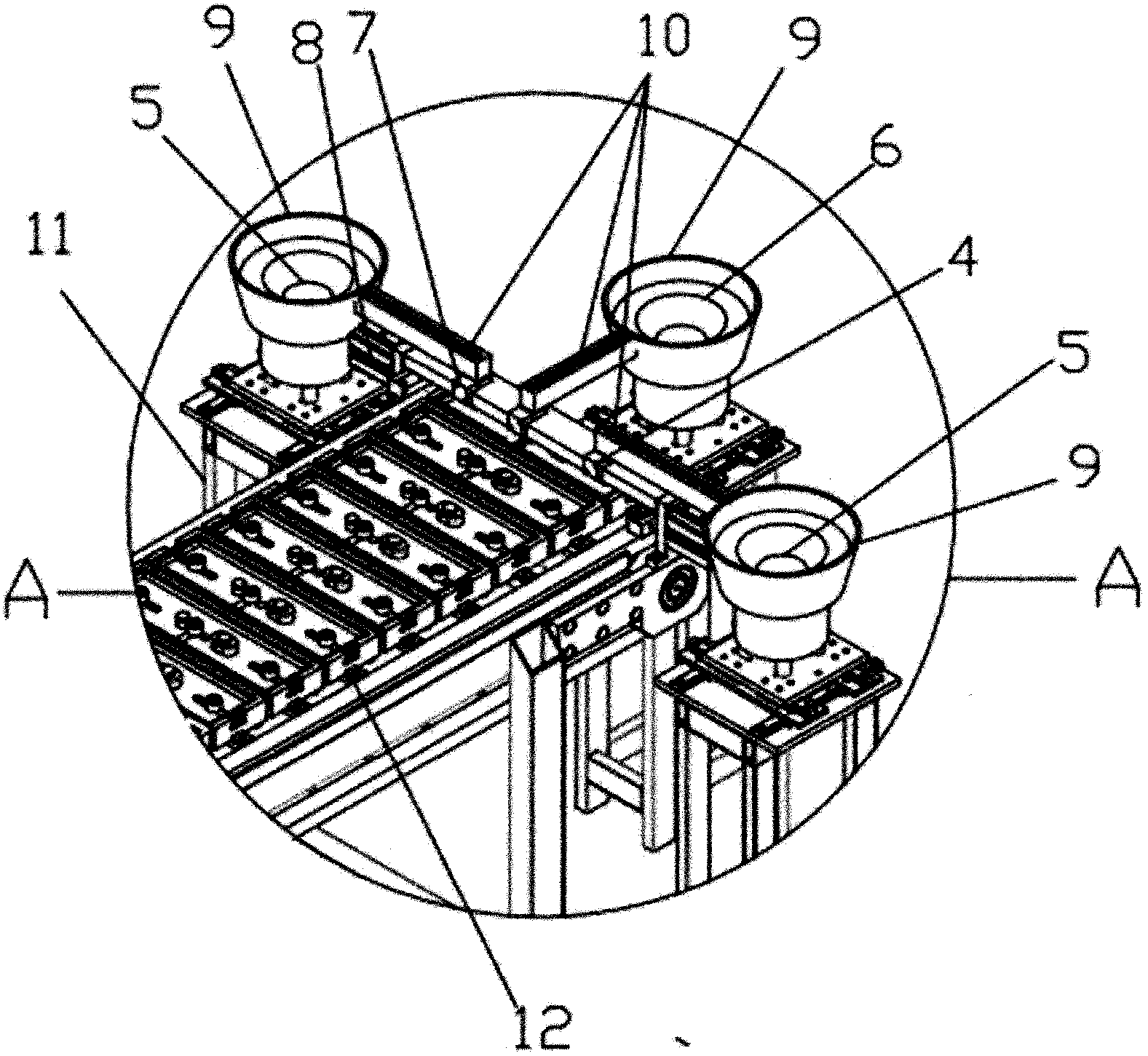

[0024] In this embodiment, refer to Figure 1 to Figure 7 , a kind of automatic butt welding machine of lock panel, it comprises frame 1, and the feeding mechanism that is arranged on frame 1 one end (such as image 3 ), and the blanking mechanism 2 that is arranged on the other end of the frame, and the transmission mechanism 3 that is arranged on the frame 1, and some working modules that are arranged on the transmission mechanism 3 (such as Figure 5 ), and the butt welding mechanism fixed on the frame 1 (such as Figure 4 ), in addition, a PLC control system is provided to control the entire mechanical operation steps.

[0025] The feeding mechanism (such as image 3 ) includes the blanking module 4, the stud feeding mechanism 5 and the pin feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com