Movable bracket

A technology for moving brackets and racks, which is applied in the field of brackets supporting steel pipes, which can solve problems such as increased equipment costs, lack of adjustment functions, and increased maintenance costs, and achieves the effects of low cost, convenient modification, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

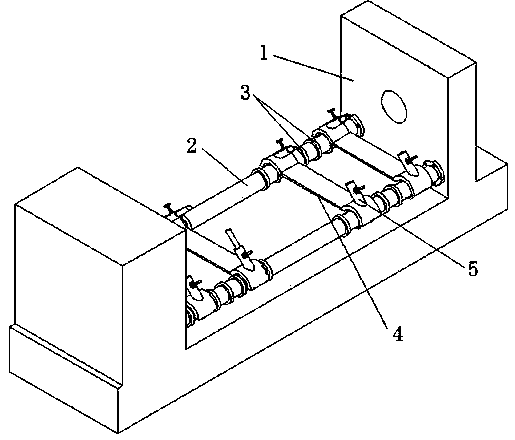

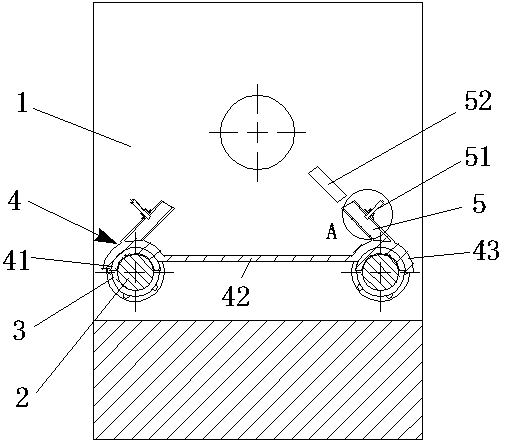

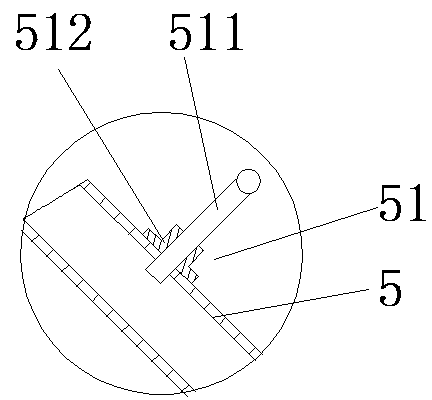

[0017] Example 1, such as Figure 1-2 Shown, a kind of mobile support comprises frame 1, is arranged on two circular guide rods 2 on frame 1, and 14 retaining rings 3 are all set on described each guide rod 2, and described retaining ring 3 Set at both ends of the guide rod 2. One end of the guide rod 2 is provided with seven retaining rings 3, and the distance between two adjacent retaining rings 3 is 80 mm. Two adjacent retaining rings 3 are connected to support members 4; there may be multiple support members 4, and there are four in this embodiment. The support member 4 includes an arc-shaped limiting block 41 snapped into the retaining ring 3 , and the arc-shaped limiting block 41 can increase contact with the guide rod 2 and increase friction and blocking effects. In order that the limiting block 41 can be easily inserted into the two retaining rings 3 , the width of the limiting block 41 is 1-5 mm smaller than the distance between two adjacent retaining rings 3 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com