Feeding device for wood chipper

The technology of a feeding device and chipper is applied in the manufacture of thin wood chips, wood processing equipment, metal processing and other directions, which can solve the problems of hidden danger, time-consuming and labor-intensive, labor-intensive and time-consuming, and achieve convenient feeding work and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

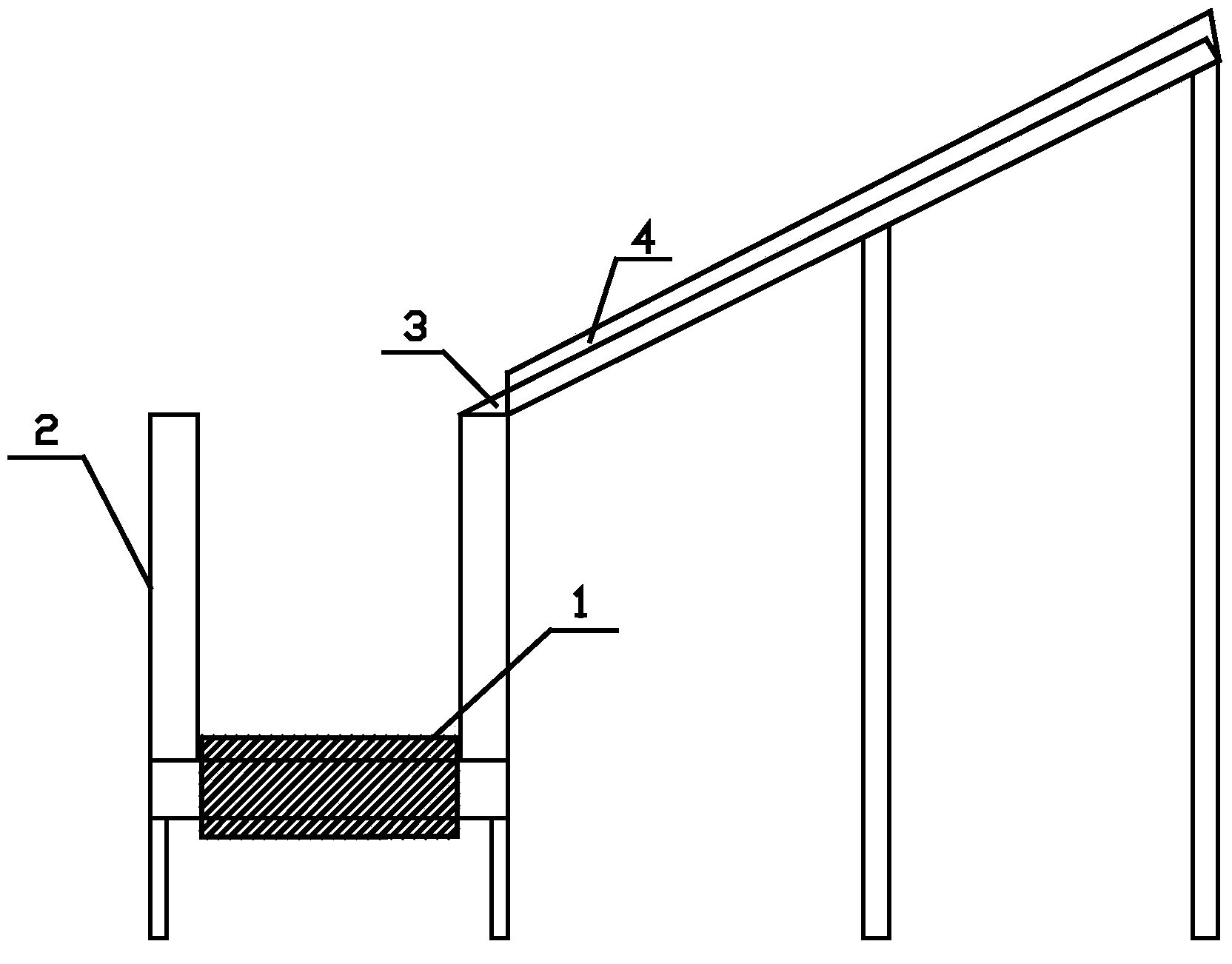

[0013] The invention provides a feeding device of a wood chipper, such as figure 1 Shown, comprise electric conveyer belt 1, electric conveyer belt 1 place is provided with U-shaped groove 2, and U-shaped groove 2 side is provided with slope shape wood storage board 3.

[0014] like figure 1 Shown, wherein the angle of slope-shaped wooden storage board 3 slopes and horizontal plane is 10-50 degree is the best, if exceed above-mentioned angle easily cause material to slide rapidly, can not effectively finish quantitative feeding. Slope-shaped wooden storage board 3 both sides are provided with blocking plate 4, prevent material from sliding down from the both sides of slope-shaped wooden storage board 3. The U-shaped groove 2 is arranged in the conveyor belt of the motorized conveyor belt 1 .

[0015] In the present invention, by pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com