Combined anti-collision beam

An anti-collision beam and combined technology, applied in the direction of bumpers, doors, vehicle parts, etc., can solve the problems of unfavorable weight reduction of the whole vehicle, increase the cost of anti-collision beams, consume collision energy, etc., and achieve strong and reasonable structure. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

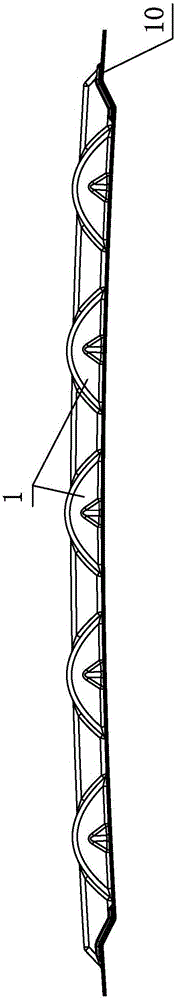

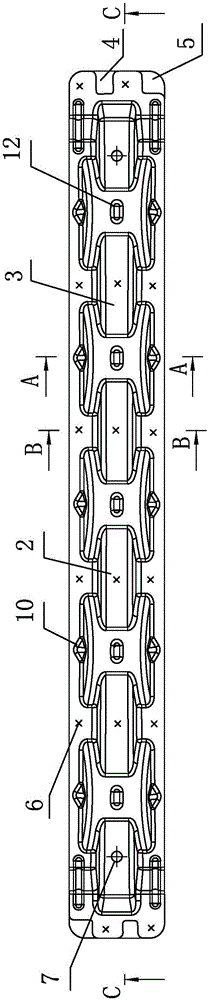

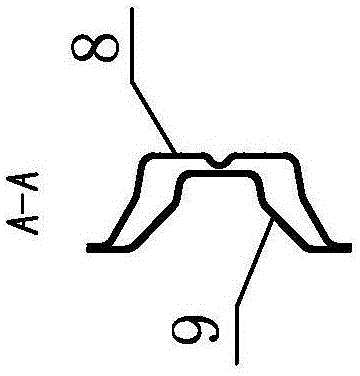

[0020] Embodiment: A combined anti-collision beam according to the present invention includes fastened inner panels 9 and outer panels 8. Both the inner panels 9 and the outer panels 8 are strip-shaped and protrude in the middle to form bosses. The bosses The two ends extend along the length direction of the inner plate 9 and the outer plate 8, and the boss 2 on the outer plate 8 is provided with several arched platforms 1; Connecting; the body of the arch platform 1 spans both sides of the boss 2 on the outer plate 8 or one side of the boss 2 placed on the outer plate 8 .

[0021] The top surface of the arched platform 1 is higher than the boss 2 on the outer plate 8 , and the boss 2 runs through the body of the arched platform 1 . The arched platform 1 is arranged on the boss 2 of the outer panel 8 along the length direction of the outer panel 8, and the combination of the boss 2 and the arched platform 1 forms an arch bridge shape. Adjacent arch platforms 1 are connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com