Low-bubble photo-curing adhesion agent

A light-curing, adhesive technology, used in adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problem of poor compatibility of defoamer, difficult to completely eliminate large bubbles, Can't use etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Put the raw materials into the stirring tank according to the ratio, keep the temperature at 50 degrees, the vacuum at -0.08~-0.1MPa, the speed at 200r / min, stir for 40 minutes to 1 hour, and finally continue to vacuum for 10 to 15 minutes. Filtrate the material to get the finished product.

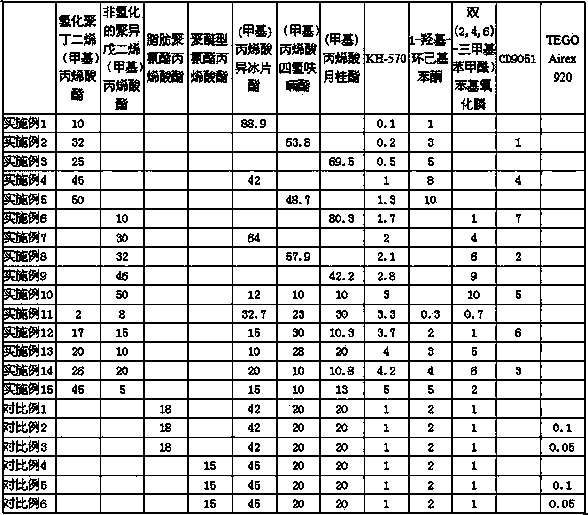

[0013] The raw material proportions of each embodiment and comparative example are shown in Table 1. In the comparative example, TEGO Airex 920, a defoamer commonly used in photocurable adhesives with better defoaming effect, was used

[0014] Table I:

[0015]

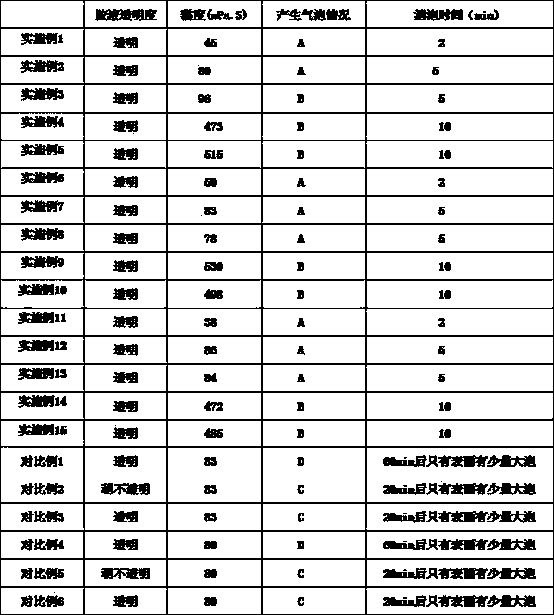

[0016] First, according to the specific implementation method and the ratio of raw materials of each embodiment and comparative example in Table 1, the finished glue is produced, and a certain amount is weighed to observe its transparency and measure its viscosity at 25 degrees. Then use 250ml plastic tanks to take 100 grams each, fix the stirring height, the stirring speed is 300r / min, and the stirring time is 5min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com