Tubular pile centering device for slant well drilling rig

A technology of centering device and inclined vertical well, which is applied to drill pipe, drill pipe, casing, etc., can solve the problems of poor pipe string centering effect, low work efficiency, poor safety, etc., and achieve good pipe string alignment, Simple processing procedures and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

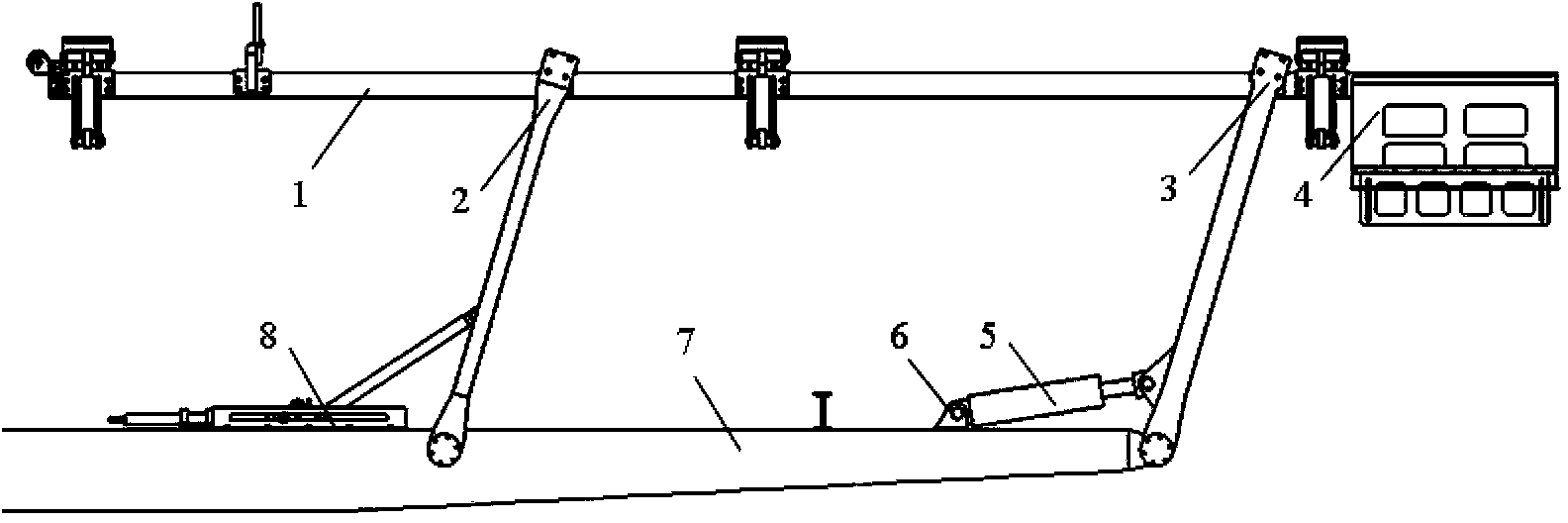

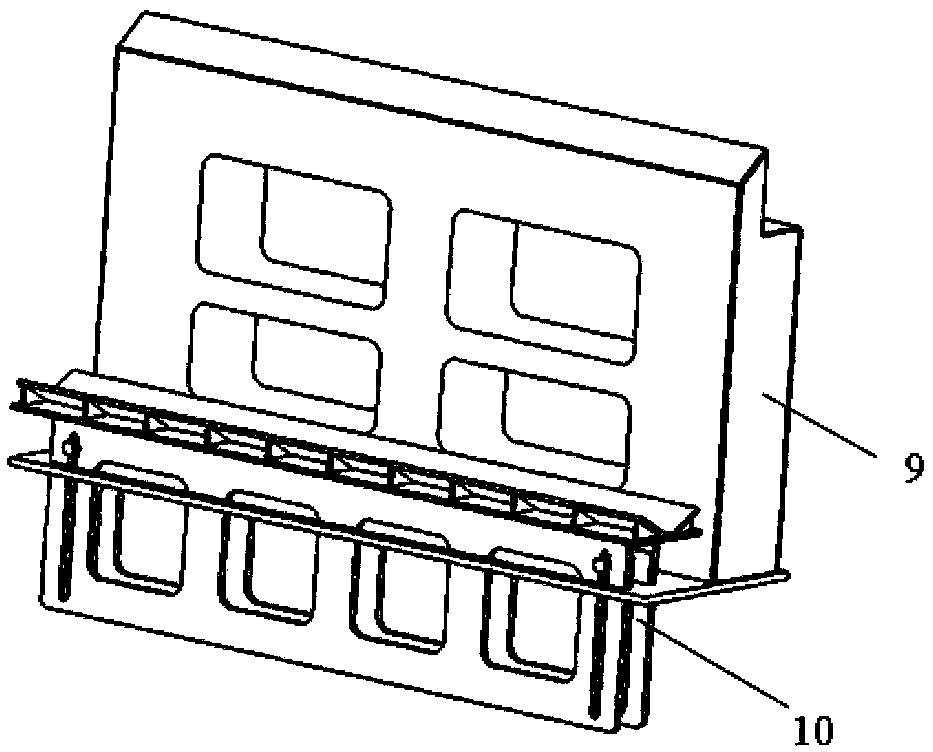

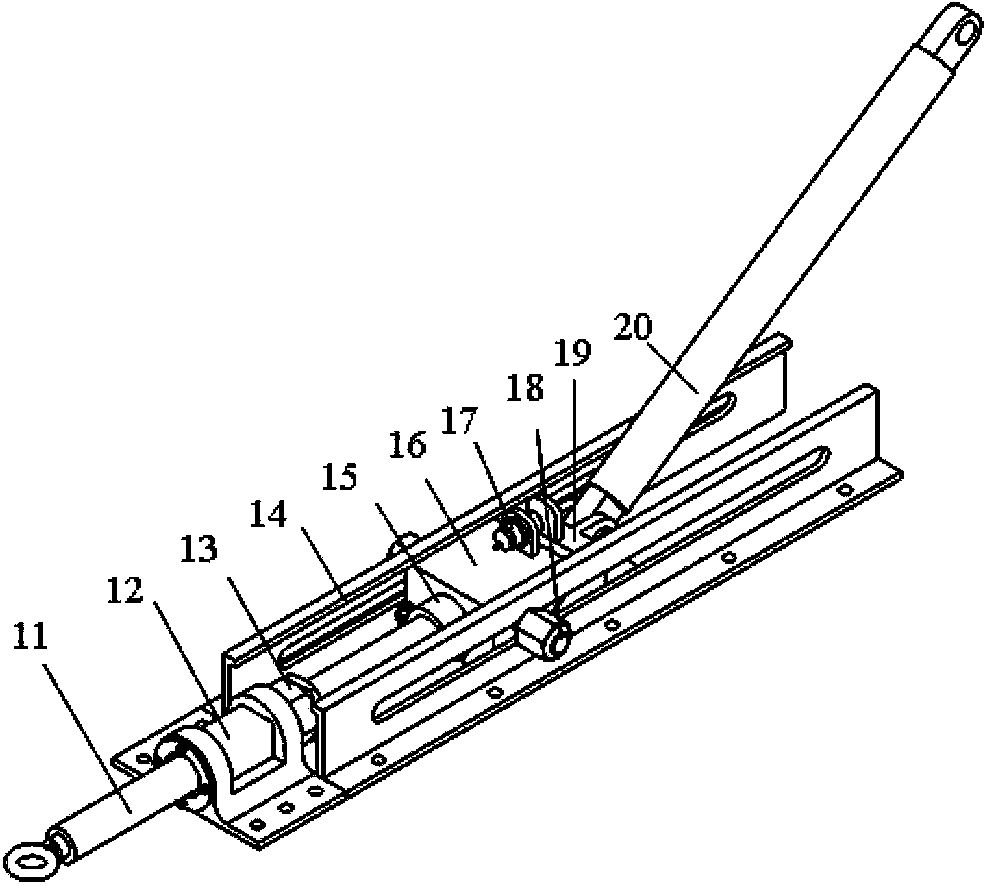

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a pipe string centering device for an inclined vertical well drilling rig includes an auxiliary arm 1, a rear connecting rod 2, a front connecting rod 3 and a boom 7; both ends of the front connecting rod 3 and the rear connecting rod 2 pass through the rotating shaft Connected on the auxiliary arm 1 and the main arm 7, the mechanical limit device 4 is welded on the auxiliary arm 1, the screw seat 12 and the guide rail 14 on the distance adjustment device 8 are connected to the main arm 7 by bolts, the distance adjustment device 8 The support rod 20 is connected with the rear connecting rod 2 through the pin shaft, the hydraulic cylinder base 6 is welded on the boom 7, and the hydraulic cylinder 5 used in conjunction with the hydraulic cylinder base 6 is connected to the front connecting rod 3, and the hydraulic cylinder 5 stretches to realize the mechanism starting. Lifting dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com