wide area overshot

An overshot, wide-area technology, applied in wellbore/well components, earth-moving drilling, etc., can solve problems such as inability to achieve salvage and carry, achieve strong reusable functions, improve operation efficiency and success rate, and improve operation. effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

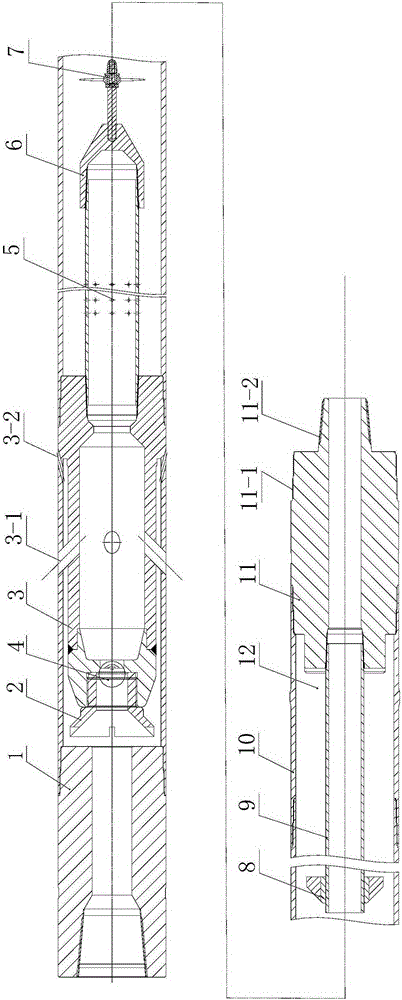

[0017] see figure 1 , the wide-area overshot, including the top joint 1, the circulation joint, the outer cylinder 10 and the lower joint which are connected in sequence, and the circulation joint is provided with a ball seat 2 (liquid flow reversal). The circulating joint is a three-connected four-way joint 3, and a plurality of groups of circulating outlets that can change the circulating flow direction and local reverse circulation are made on the pipe wall of the three-connected four-way joint, and are connected at the other end of the three-connected four-way joint. There is a sand filter and an inner cylinder 9, and the other end of the sand filter is connected with a cyclone separator 7. The lower joint is a four-connection double-pass joint 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com