Fan tower load shedding method based on separated engine room

A wind turbine tower, separate technology, applied in the field of reducing tower vibration and reducing wind turbine tower load, can solve the problem of reducing tower load and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments will illustrate the present invention in detail.

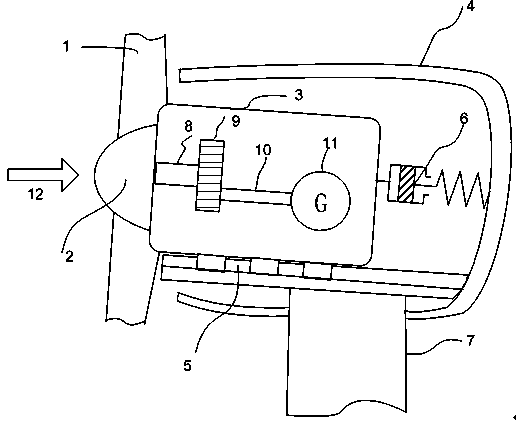

[0013] figure 1 It shows a schematic diagram of the structure of the detached nacelle for reducing the load of the tower, and shows a specific embodiment of the present invention.

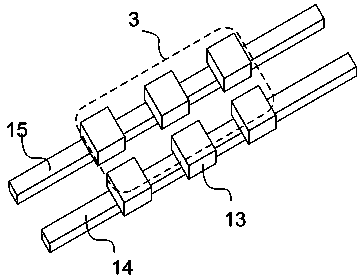

[0014] The separated cabin is composed of a sliding mass 3 and a fixed mass 4, the sliding mass 3 slides on the fixed mass 4 through the slide rail 5 at the bottom, and the bottom slide rail is regularly lubricated to reduce friction; figure 2 It is a partial schematic diagram of the slide rail, wherein the six sliders of the slide rail such as 13 are connected to the bottom of the nacelle sliding mass 3 and slide on the slide rail bases 14 and 15; the sliding mass part 3 is mainly composed of the wind wheel rotor 1 and the hub 2 , low-speed shaft 8, gearbox 9, high-speed shaft 10, and generator 11, and the fixed mass block 4 is composed of the nacelle; the sliding mass block 3 and the fixed mass block 4 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com