Linkage system based on multiway hydraulic control valve

A technology of hydraulic control valve and multi-way control valve, which is applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of unstable equipment performance, inability to automatically control, and cannot be used normally, and achieve a simple structure. , Realize the effect of remote mechanical transmission automation and ideal synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The sequential conversion opening controller of the present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

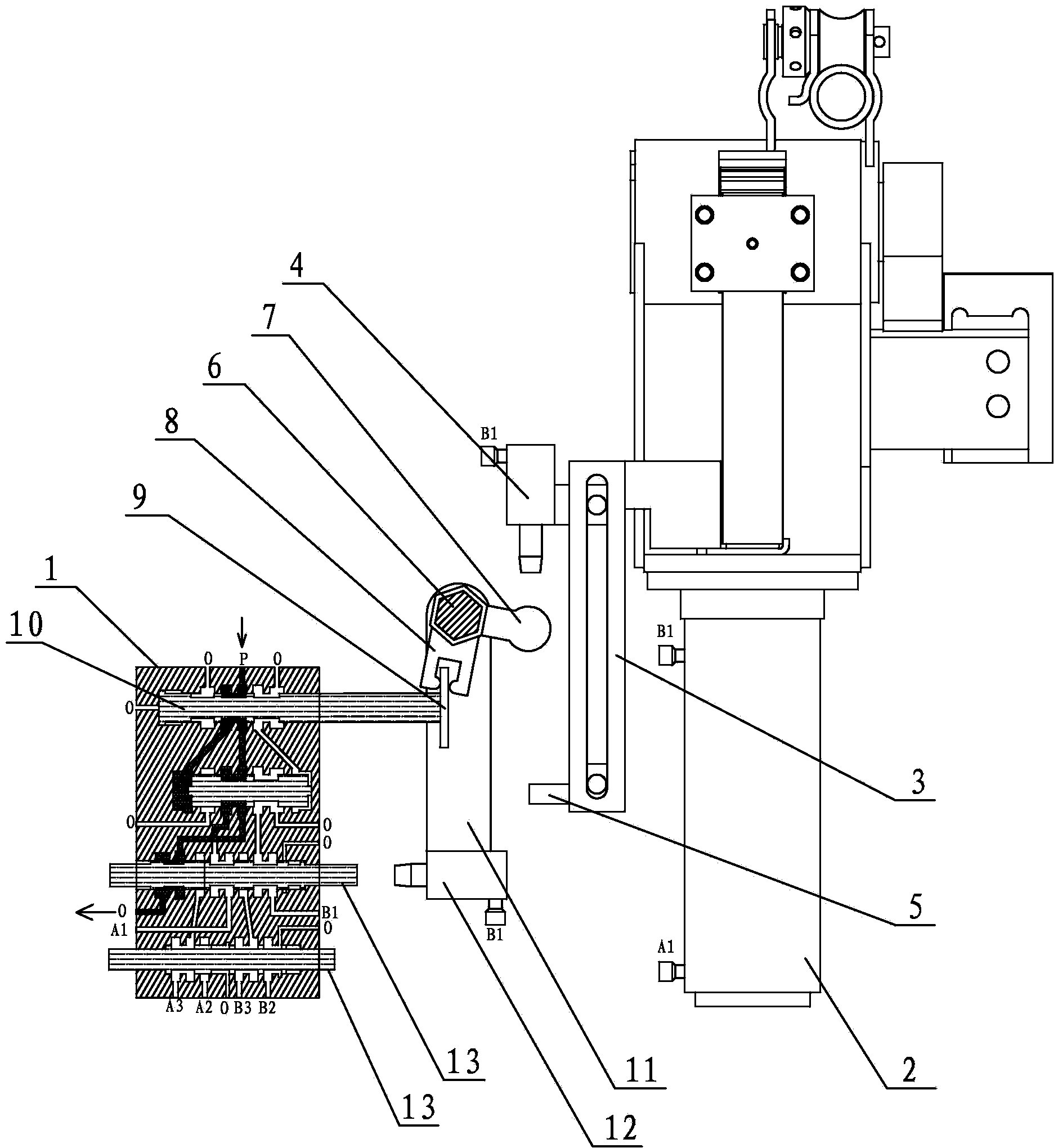

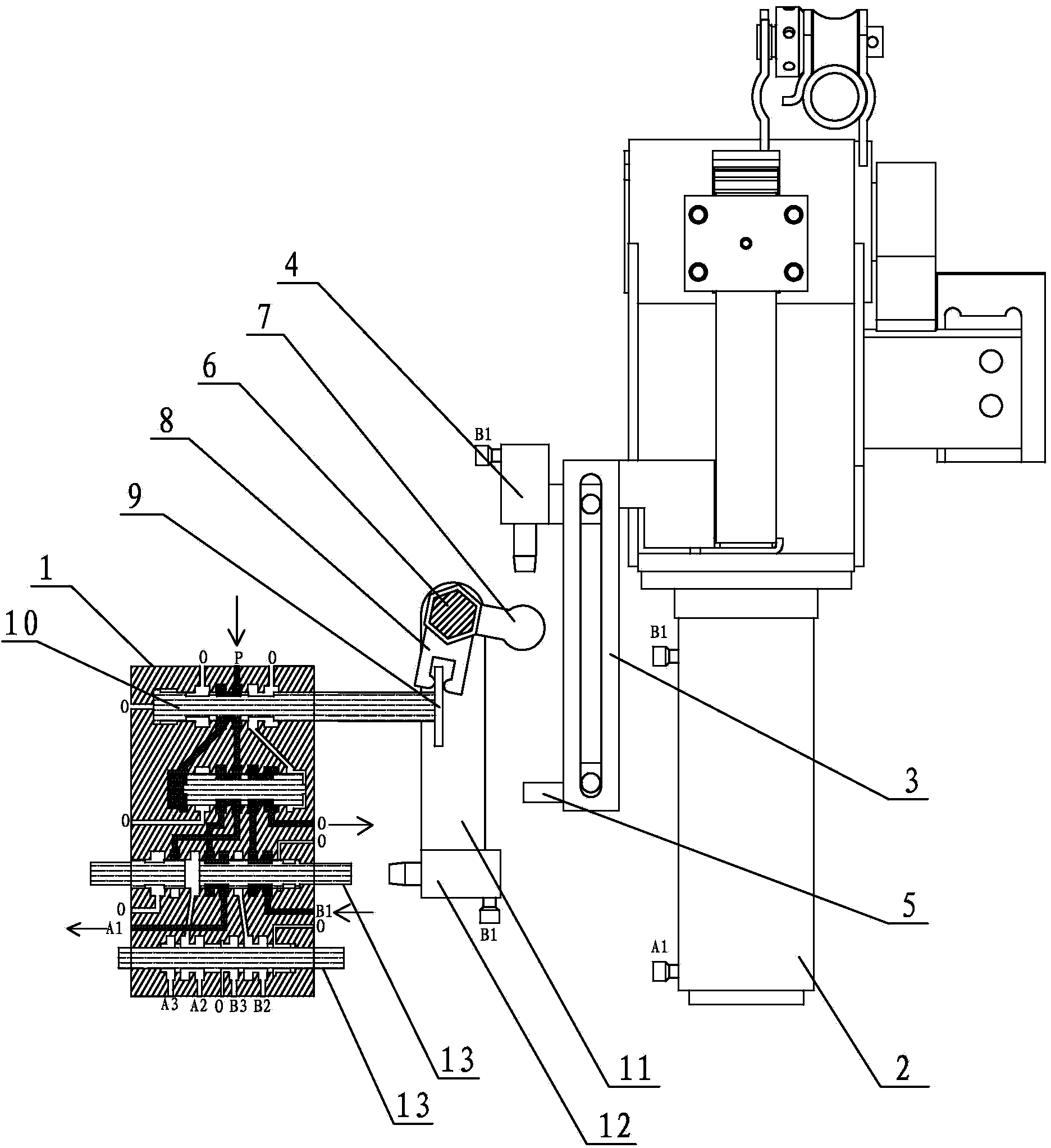

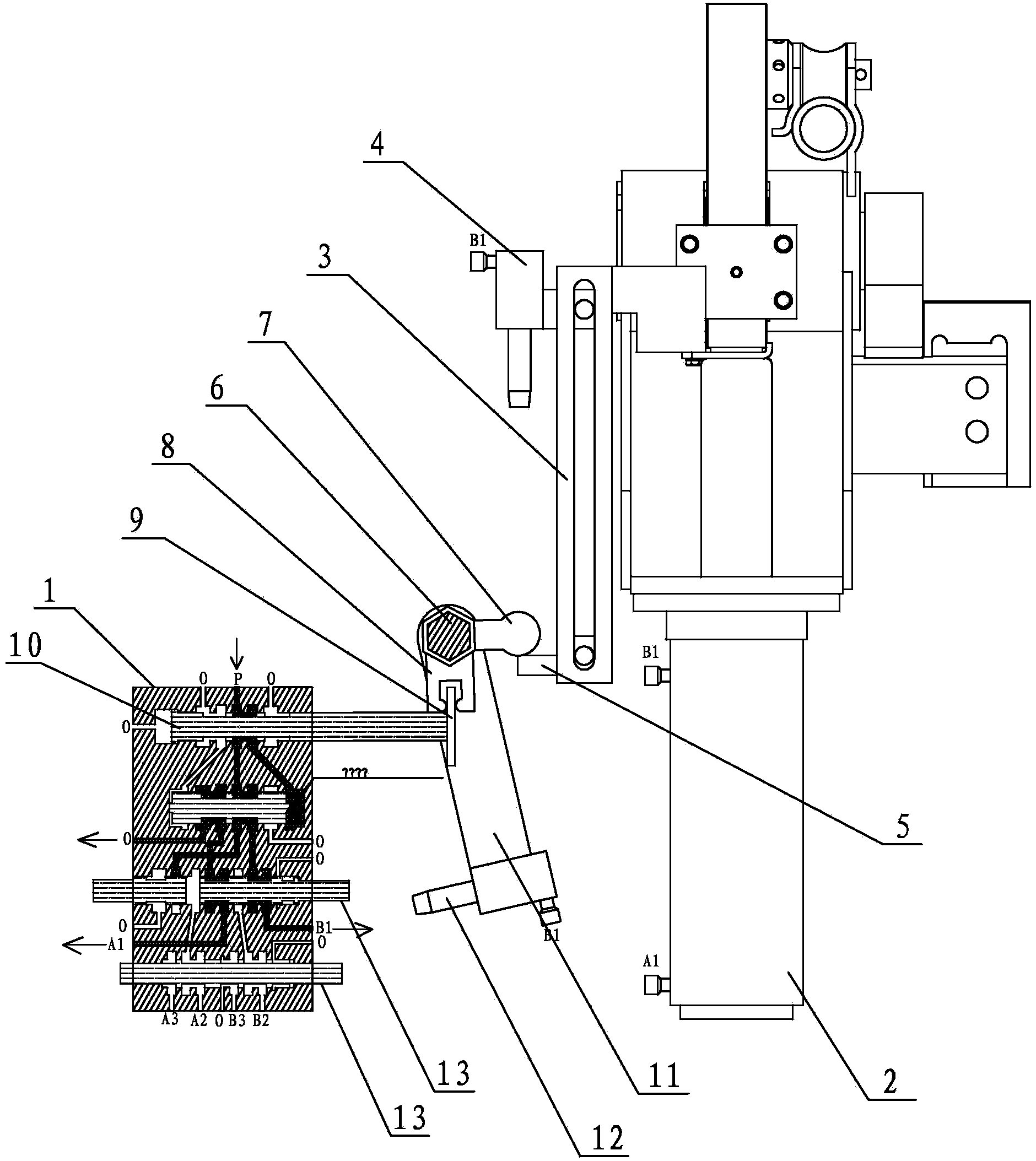

[0037] refer to figure 1 , Figure 5 with Figure 7 , one of the preferred embodiments of the present invention, includes a multi-way hydraulic control valve 1, the multi-way hydraulic control valve 1 is provided with an oil inlet connected to the oil pump and an oil discharge port connected to the oil tank, and the multi-way hydraulic control valve 1 is connected to There are multiple hydraulic cylinders 2, and the multi-way control valve 1 is provided with a reversing spool 10 for changing the flow direction of the oil circuit of the hydraulic cylinder 2 and a switching spool 13 for switching connections between multiple hydraulic cylinders 2; 2. The stroke bracket 3 is connected to the piston rod, the adjustable stroke bumper 5 is arranged under the stroke bracket 3, the first ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com