An online comprehensive detection system for oil

A comprehensive detection and oil technology, which is applied in the field of oil online comprehensive detection system, can solve the problem of single function of detection equipment, and achieve the effect of compact size, efficient and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

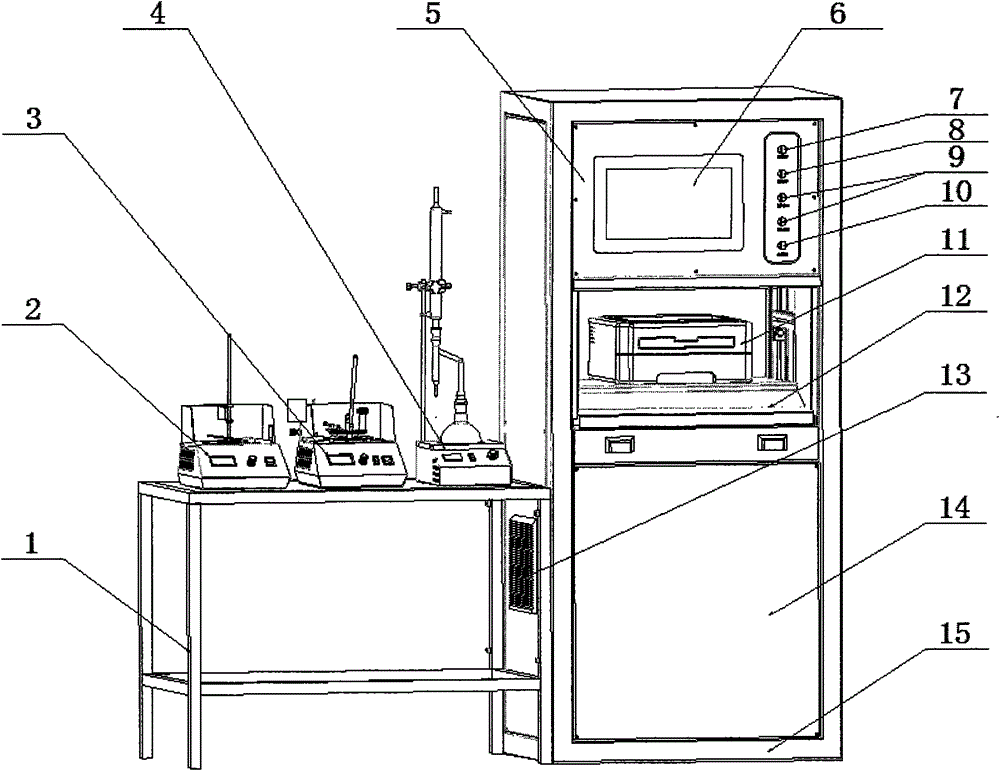

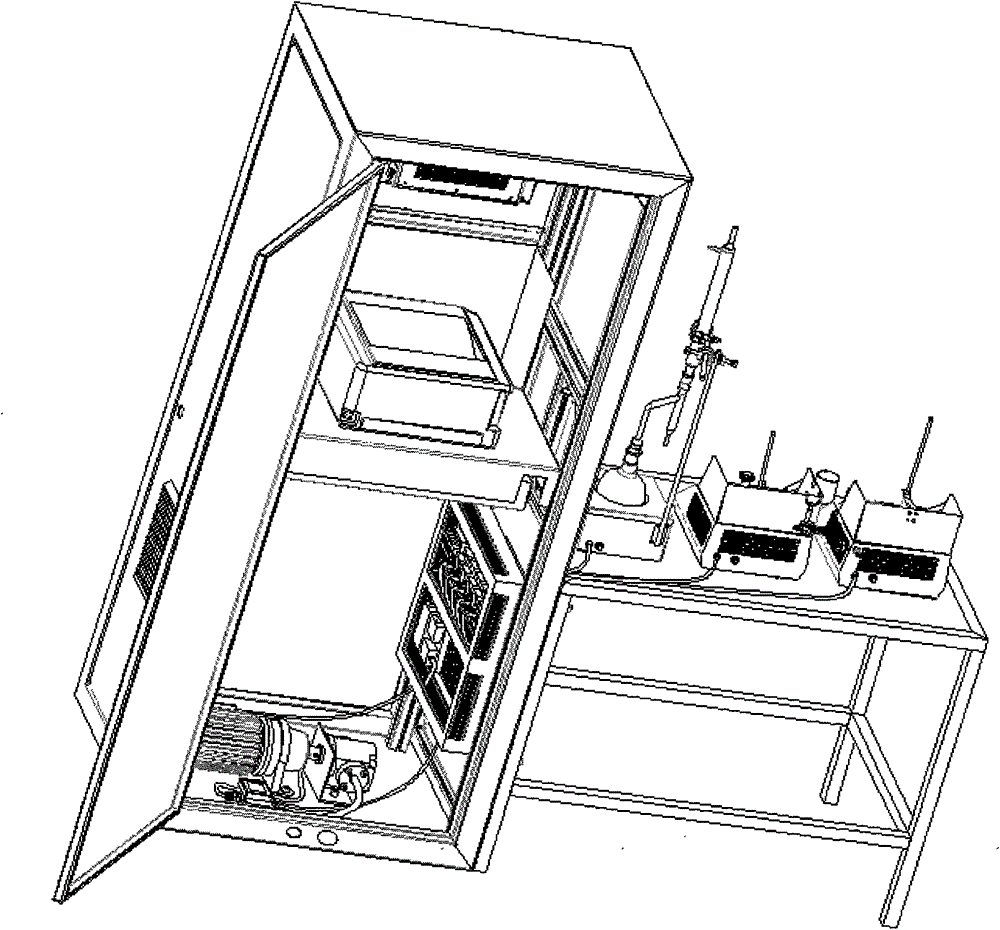

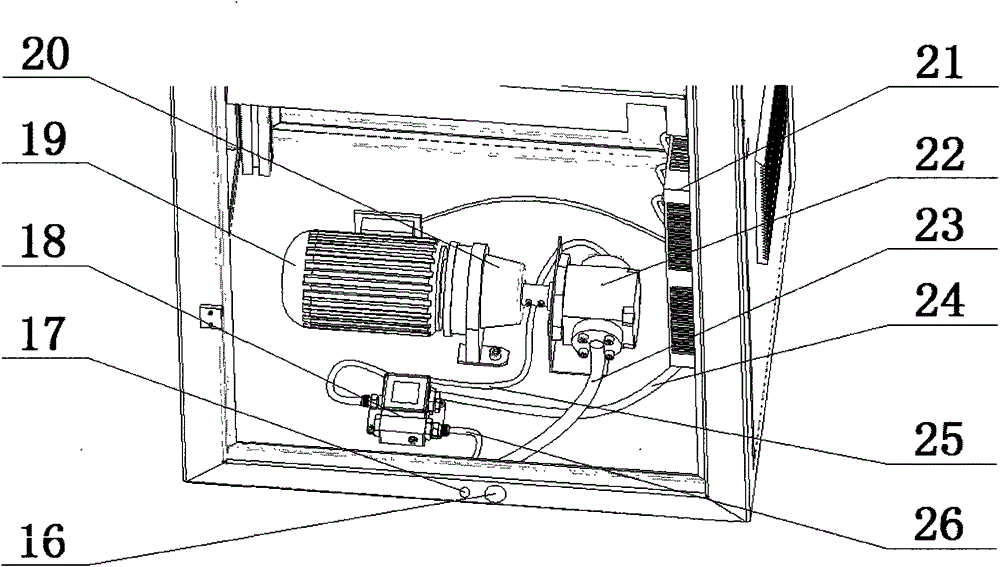

[0014] exist figure 1 with image 3 , press the power switch 10, and the power indicator light 7 will be on at this time, and at the same time, the motor 19, the oil pollution degree online detector 18, the printer 11, the oil open flash point detector 2, and the oil closed flash point detector 3. The oil moisture detectors 4 are all powered on. The motor 19 works to drive the speed reducer 20 connected with it, and the speed reducer 20 links to each other with the oil pump 22 again to drive its operation. In this way, the oil will flow into the oil pump 22 from the oil source through the oil inlet pipe 23 under the drive of the oil pump 22, and then flow back to the oil source through the connecting oil pipe 25, the oil pollution degree online detector 18 and the oil return pipe 26, thereby realizing oil recovery. Circular flow. When the oil passes through the oil pollution degree online detector 18, it will generate detection data, and then transmit it to the industrial p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com