Improvement structure of synthetic leather inspection device

An inspection device and technology for synthetic leather, applied in the field of inspection of synthetic leather, can solve problems such as affecting the surface texture of leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

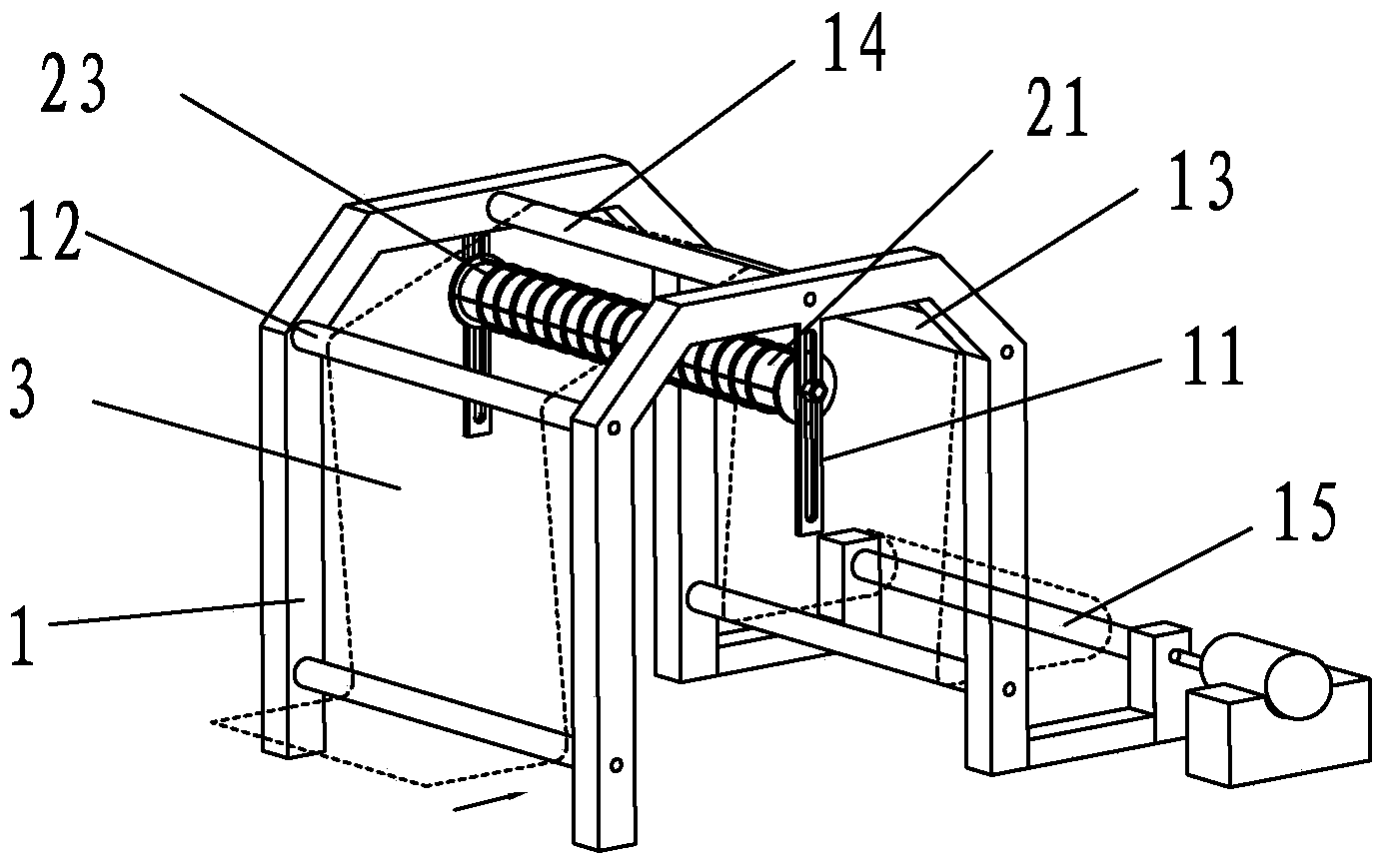

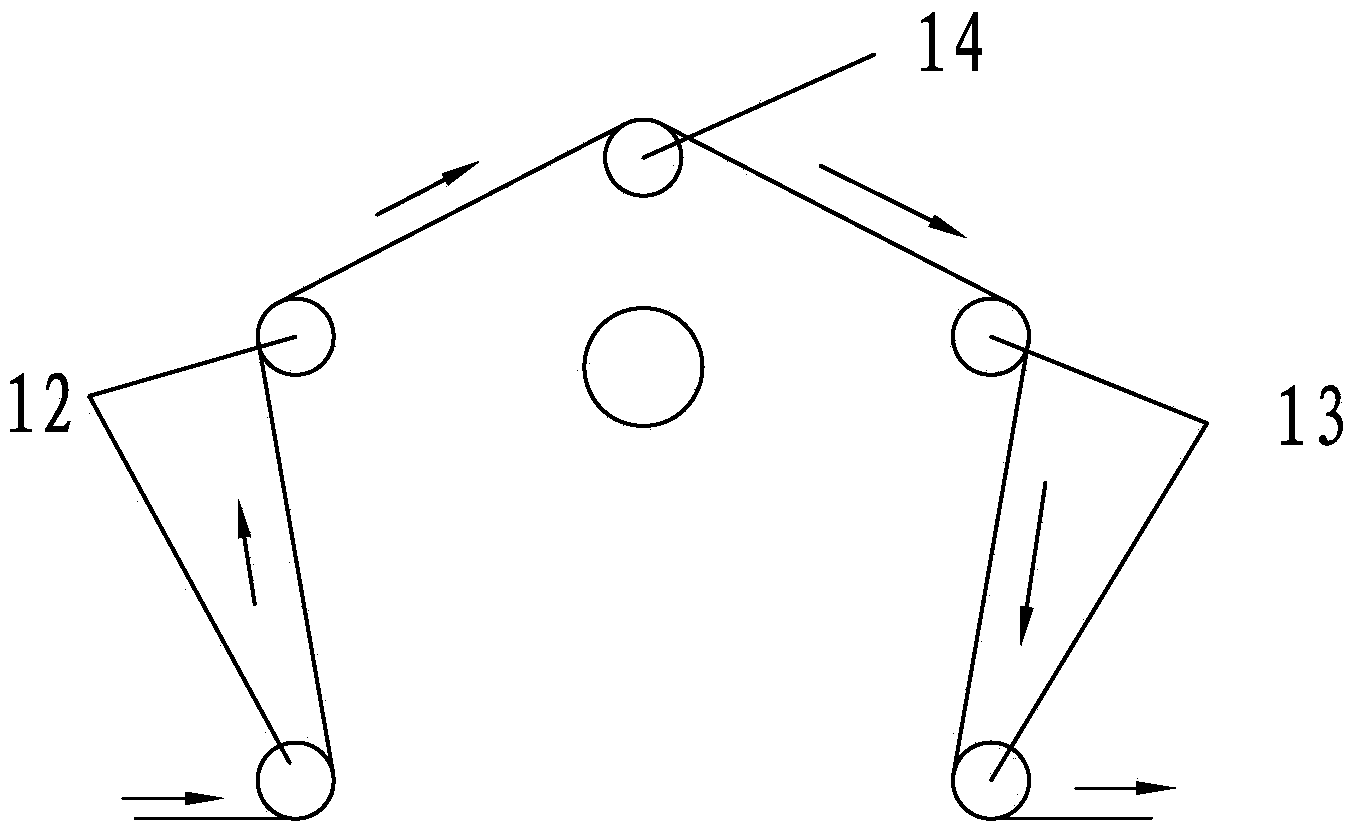

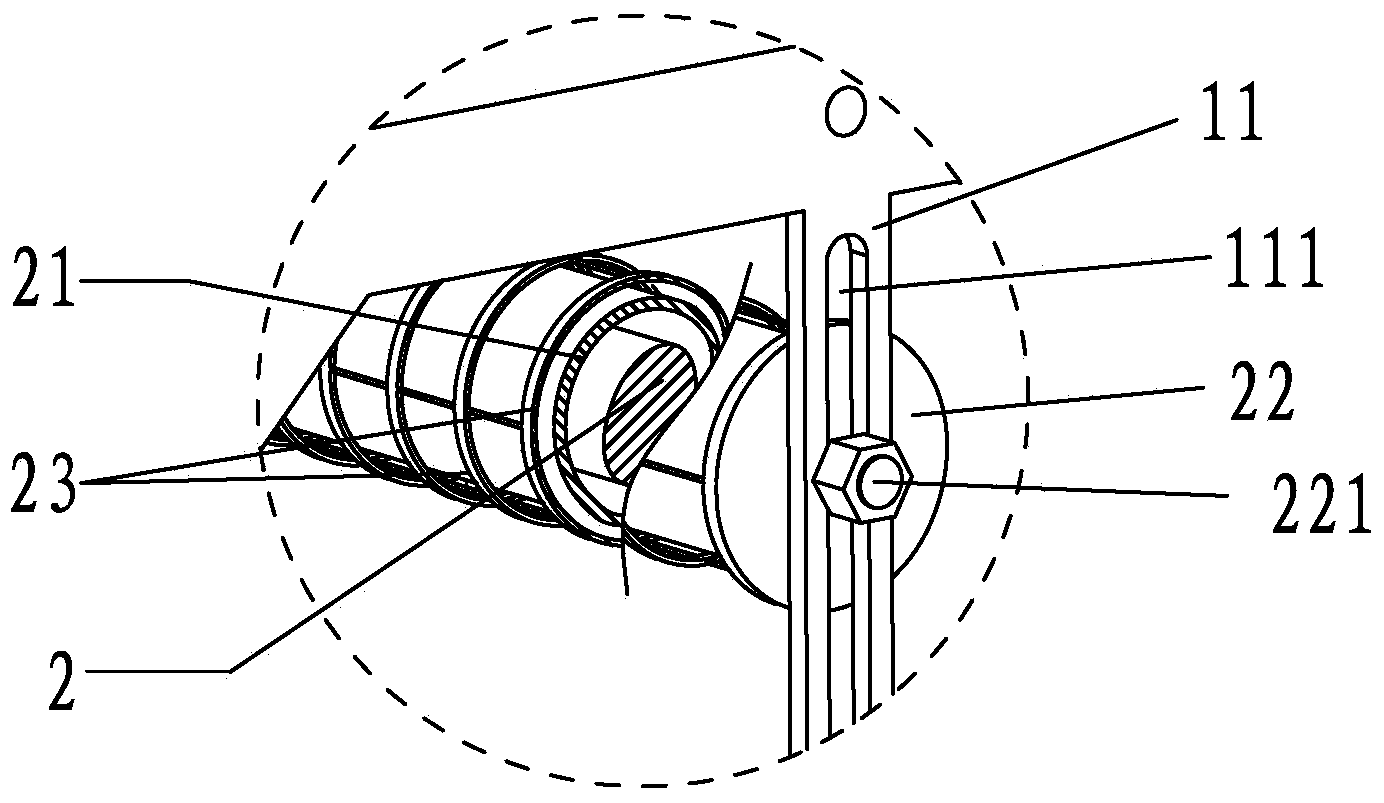

[0017] like Figure 1 to Figure 2 As shown, the inspection device mainly includes a frame 1, the synthetic leather 3 is conveyed from the lower left corner of the frame 1, and the middle of the frame 1 is vertically provided with a lamp tube mounting frame 11, and the lamp tube mounting frame 11 is respectively provided on the front and rear sides of the frame 1. Two, the lighting device is movable and fixed between the two lamp tube mounting frames. The so-called movable fixing is an adjustable fixing method. In this example, the upper and lower positions of the lighting device can be adjusted. When the adjustment is in an appropriate position, it is fixed. , so that the distance between the lighting device and the synthetic leather can be adjusted according to different lighting needs, the specific implementation is in image 3 Specifically sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com