Part surface burr detection method based on machine vision

A technology of machine vision and detection method, which is applied in the direction of instrumentation, image analysis, image enhancement, etc., can solve the problems of low detection efficiency, slow measurement speed, missed detection and wrong detection, etc., and achieve low fault tolerance rate, high accuracy, detection fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

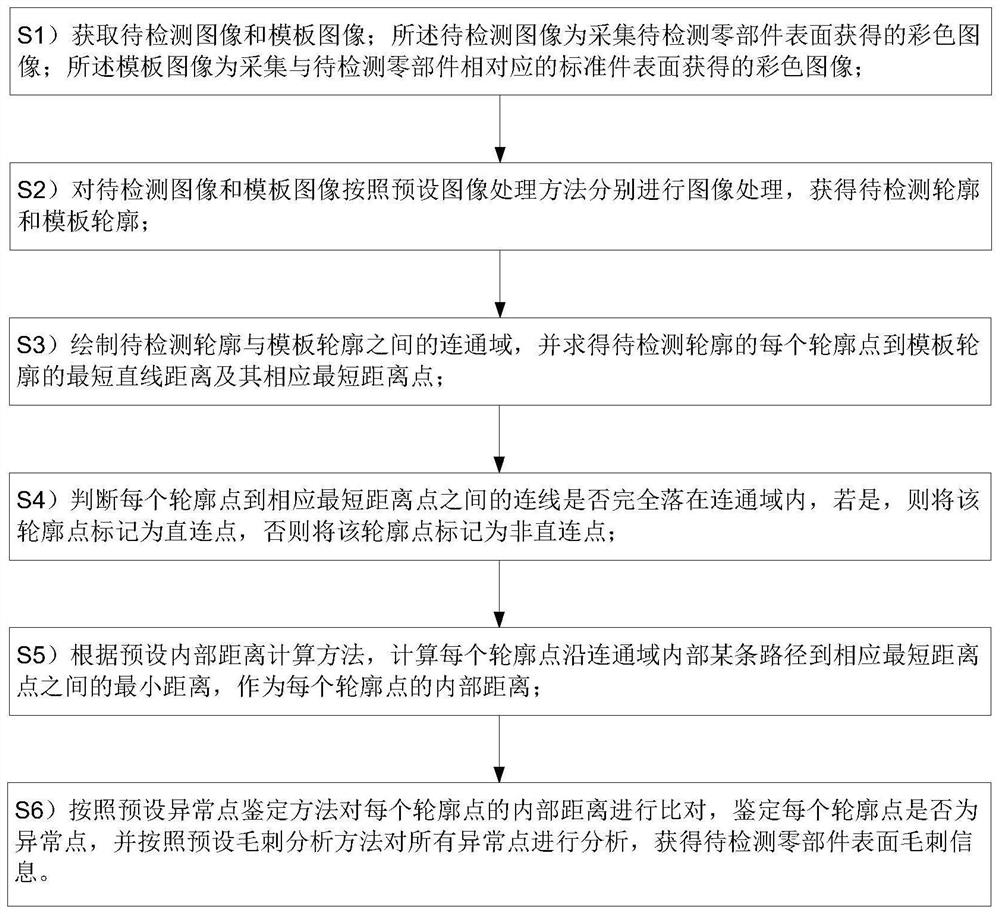

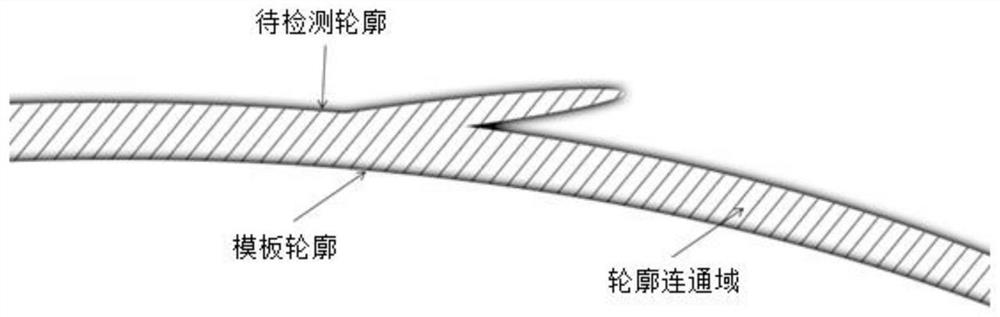

[0068] like figure 1 As shown, the present invention is based on a machine vision-based component surface burr detection method, which includes the following steps:

[0069] S1) collect the color image of the target product through a lens, an image sensor or a light source, and obtain an image to be detected and a template image;

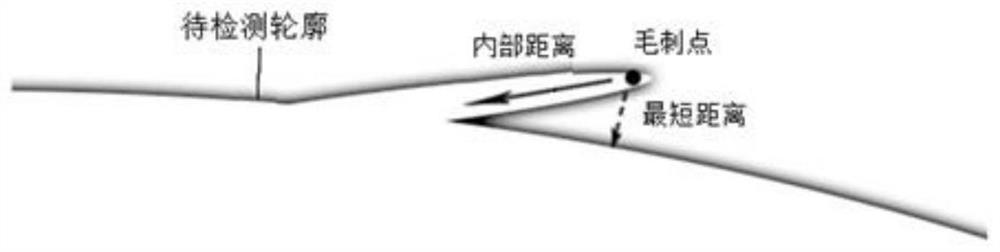

[0070] Wherein, the image to be inspected is a color image obtained by collecting the surface of the part to be inspected; the part to be inspected is figure 2 There is a burr in the range shown, the length of the burr is figure 2 the internal distance shown in the direction of the solid arrow, not the shortest distance shown in the direction of the dashed arrow;

[0071] The template image is a color image obtained by collecting the surface of the standard part corresponding to the part to be inspected; the standard part corresponds to the part to be inspected such as figure 2 No glitches in the range shown;

[0072] S2) image processing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com