Rigid cores for tire formation

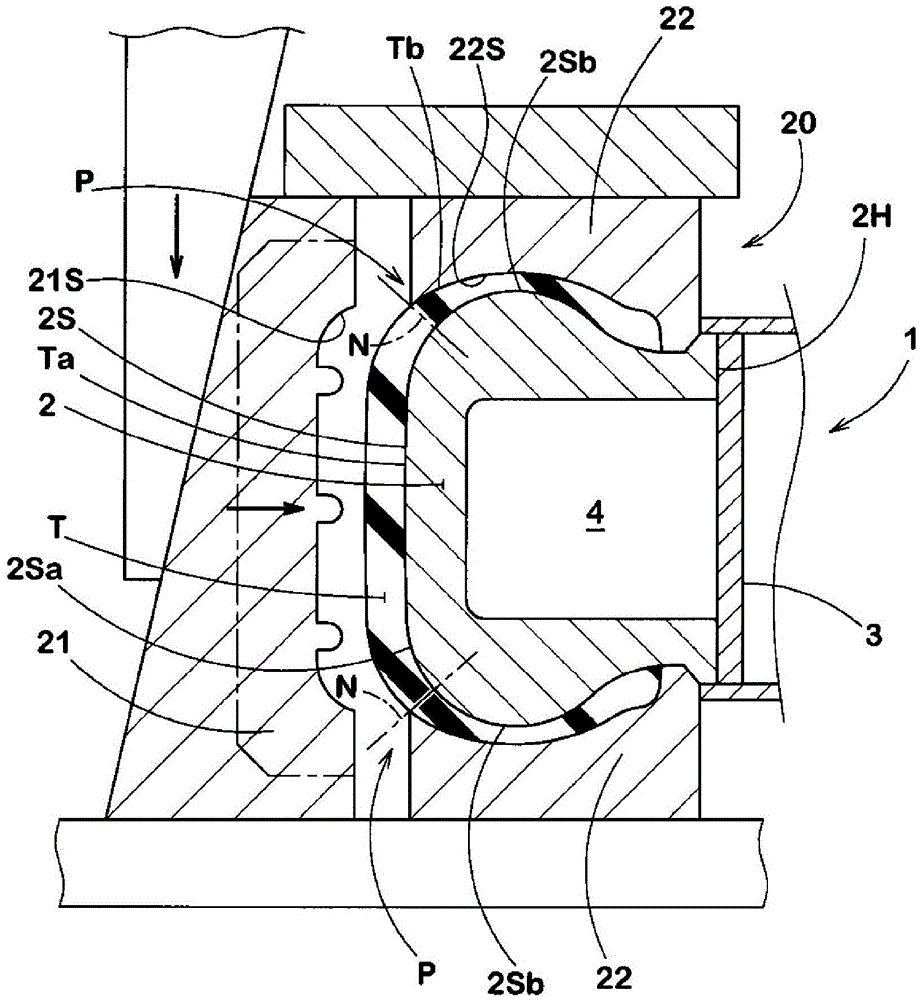

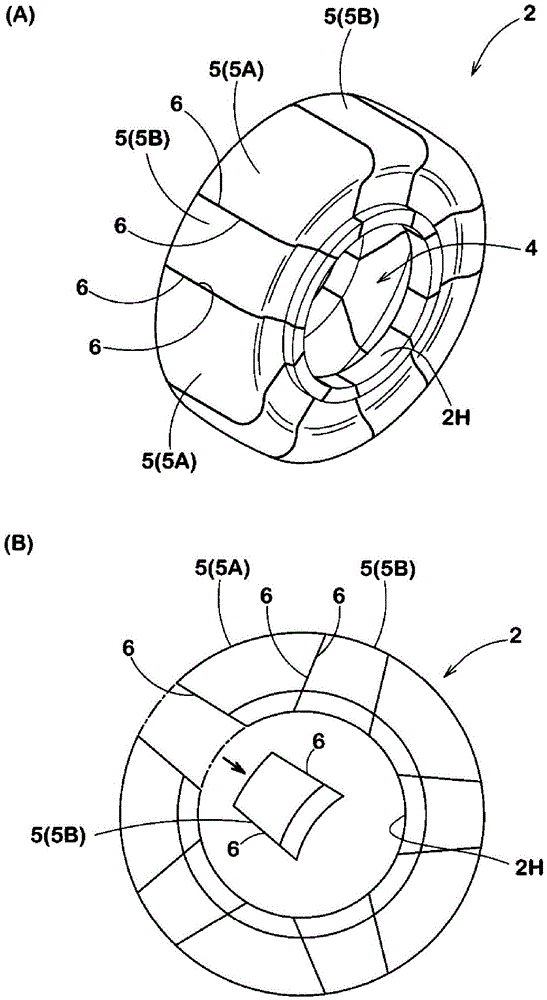

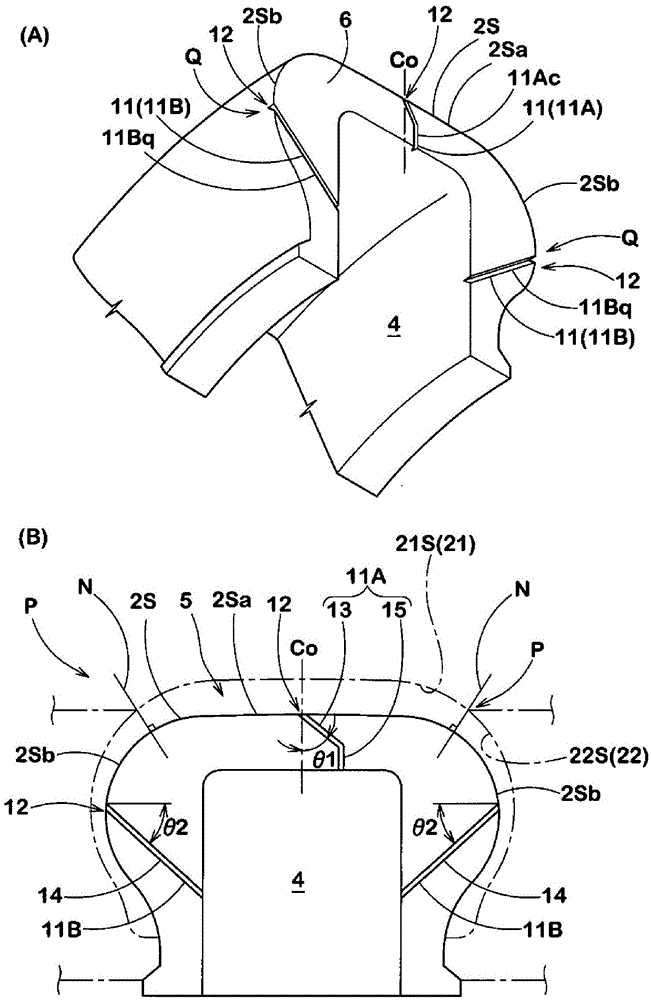

A rigid core and tire molding technology, applied in tires, applications, household appliances, etc., can solve problems such as insufficient joint strength, no consideration of rubber inflow, and reduced durability of core segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] In order to confirm the effect of the present invention, a core body for forming a pneumatic tire having a tire size of 195 / 65R15 was trial-produced based on the specifications in Table 1. In addition, when a pneumatic tire is formed using this core body, the rubber flows into the exhaust groove, the sintered rubber is sintered and adheres to the groove wall surface, and the exhaust performance is reduced due to sintering, and air is trapped. status were evaluated separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com