Sealing component for drum of washing machine and washing machine with same

A technology for sealing components and washing machines, applied in the field of washing machines, can solve the problems of difficult components, complicated maintenance operations or replacement of components, and incomplete solutions, and achieve the effect of increasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

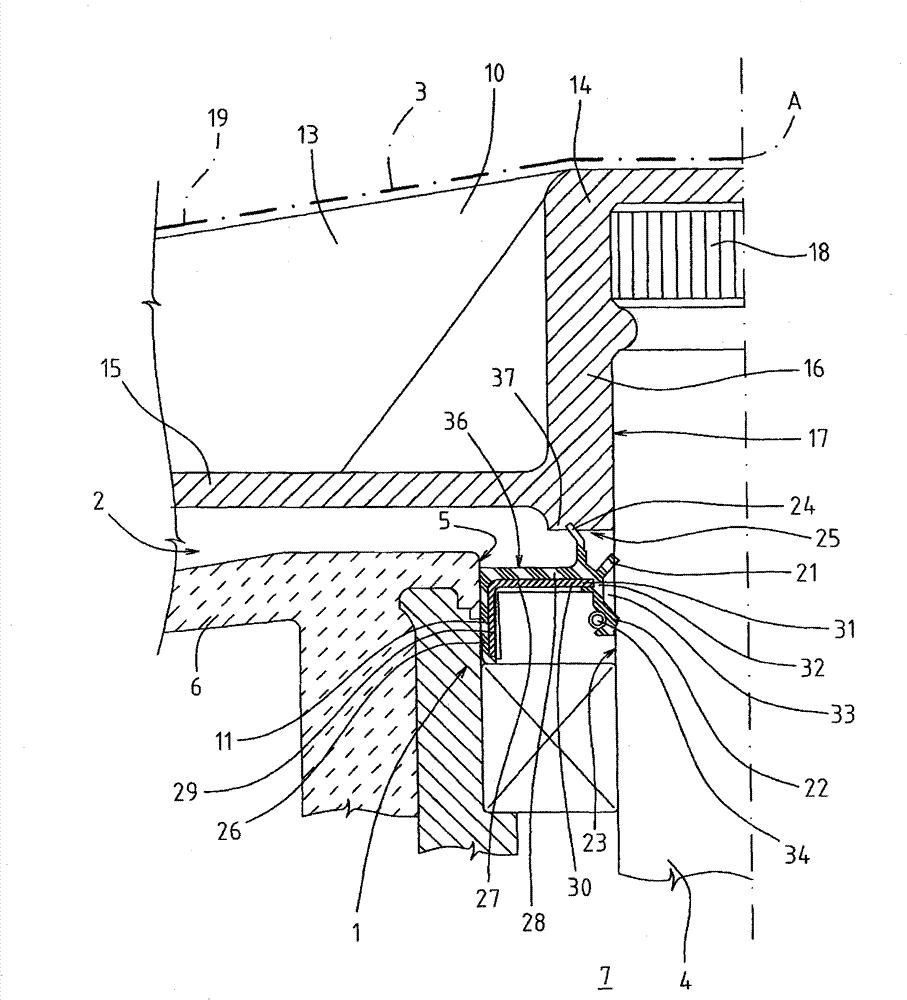

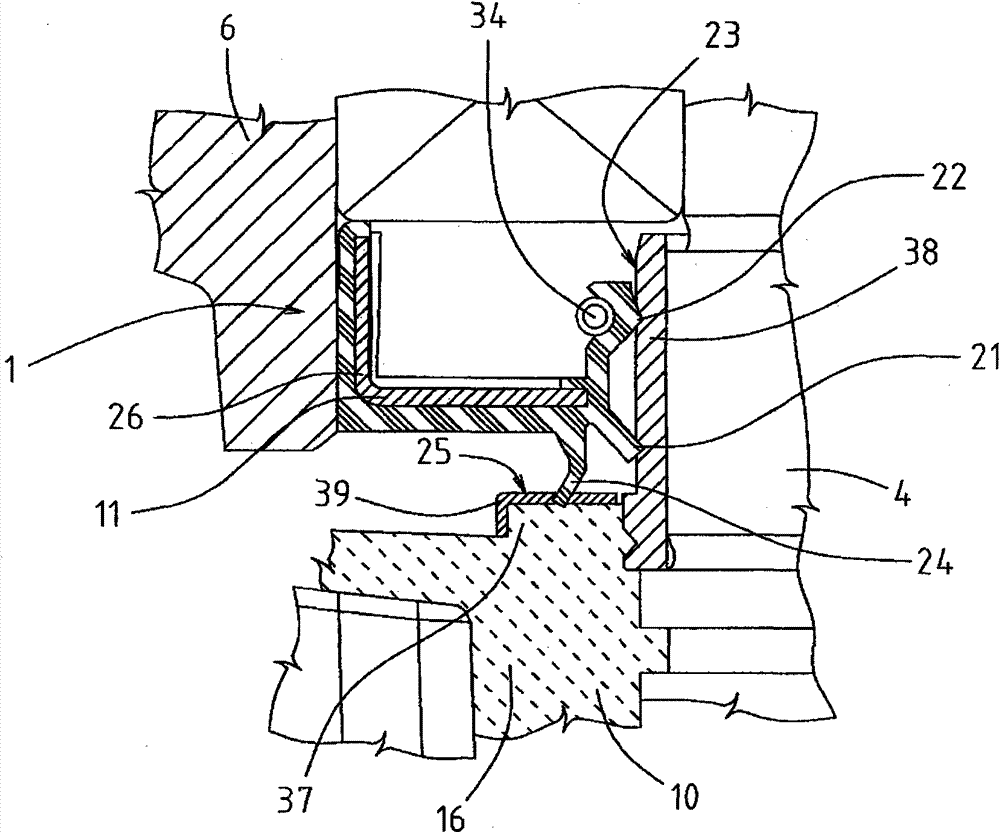

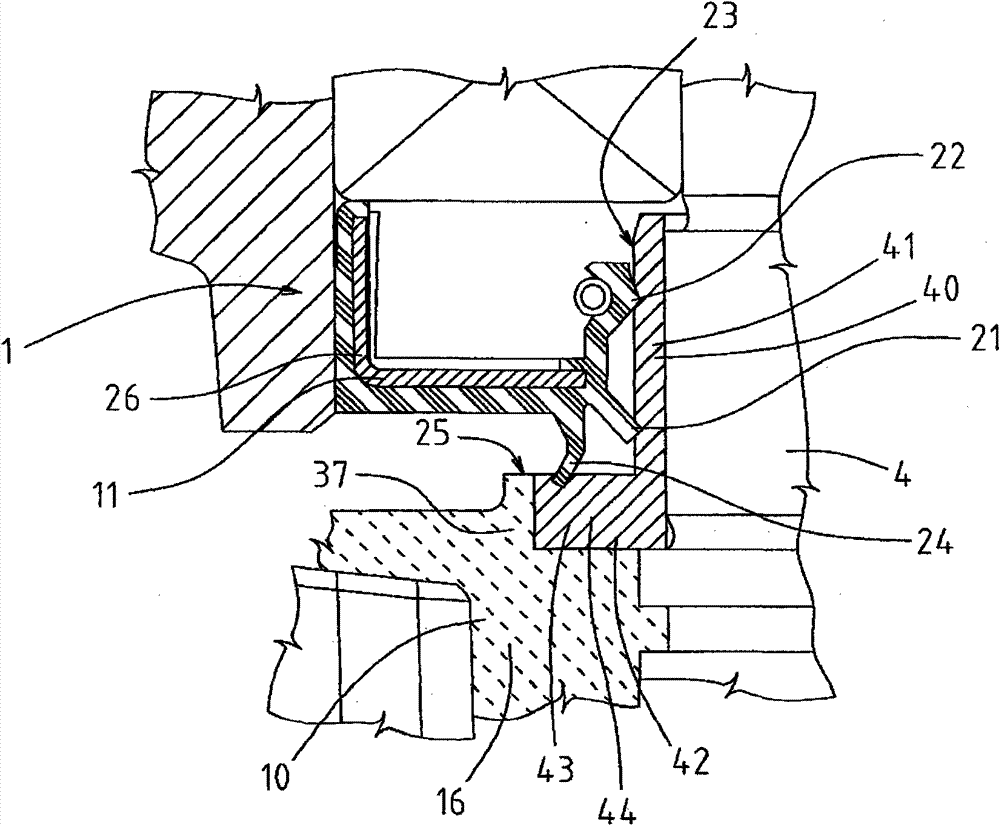

[0019] exist figure 1 In , indicated as a whole by numeral 1 is a sealing assembly for a drum of a washing machine (laundry washer).

[0020] Washing machines are known per se and are therefore not described or illustrated for the sake of brevity.

[0021] Essentially, the washing machine comprises a washing chamber 2, a drum 3 housed in the washing chamber 2 (known and figure 1 Only schematically shown in ) and a motor (not shown), the motor drives the drum shaft 4 integrally connected to the drum 3 via a specific transmission system (not shown), so that the drum 3 rotates.

[0022] Shaft 4 extends along axis A and turns about axis A (axis of rotation) and is arranged through hole 5 of wall 6 of the washing machine which separates washing chamber 2 from an auxiliary compartment 7 housing the motor.

[0023] A sealing assembly 1 separates the washing chamber 2 from a compartment 7 housing the motor in a liquid-tight manner.

[0024] In addition to the shaft 4, the sealing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com