Driving device and method for driving a load, in particular an LED assembly

一种驱动负载、设备的技术,应用在电气元件、半导体灯的使用、电致发光光源等方向,能够解决无光、放电电流未通过等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

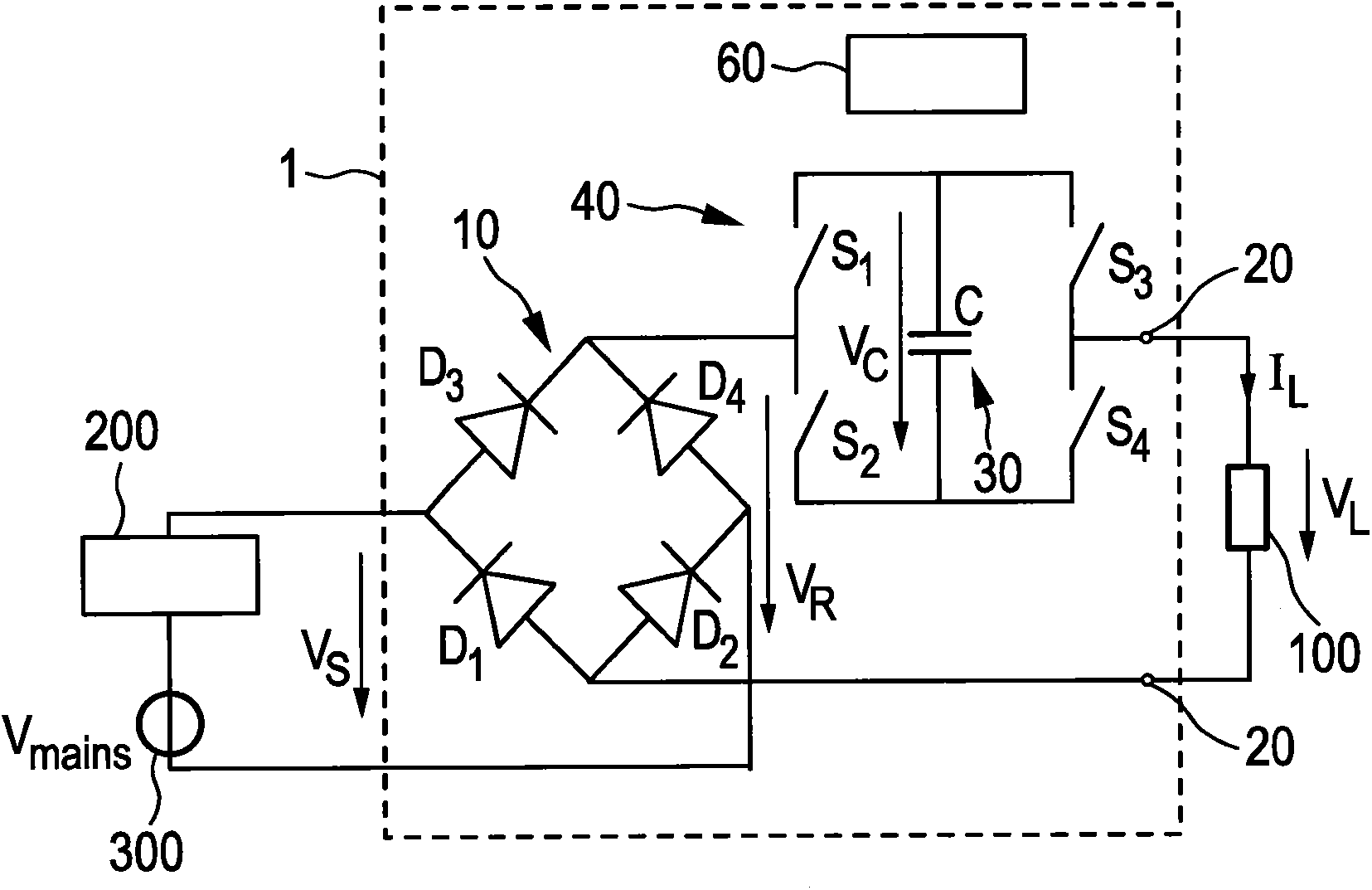

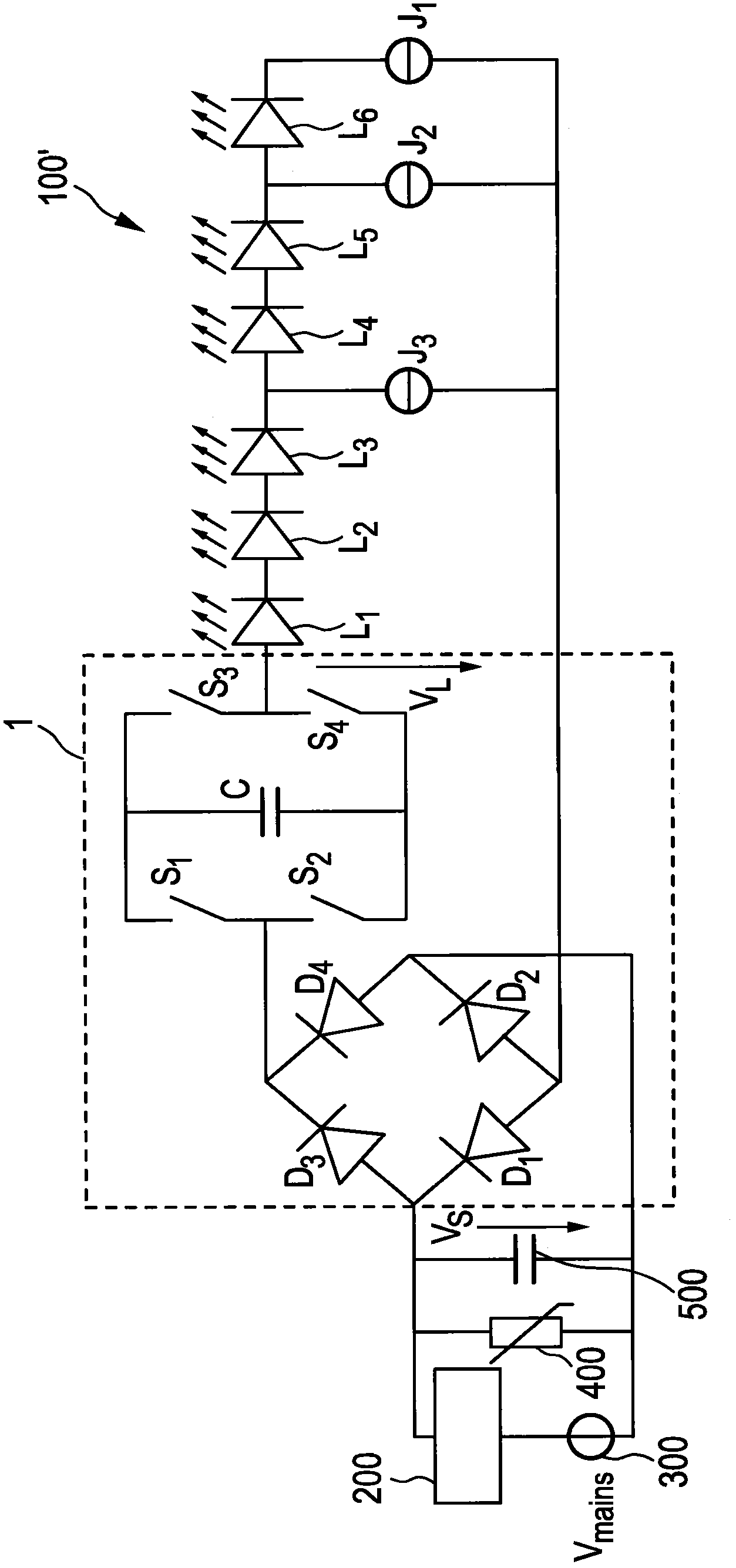

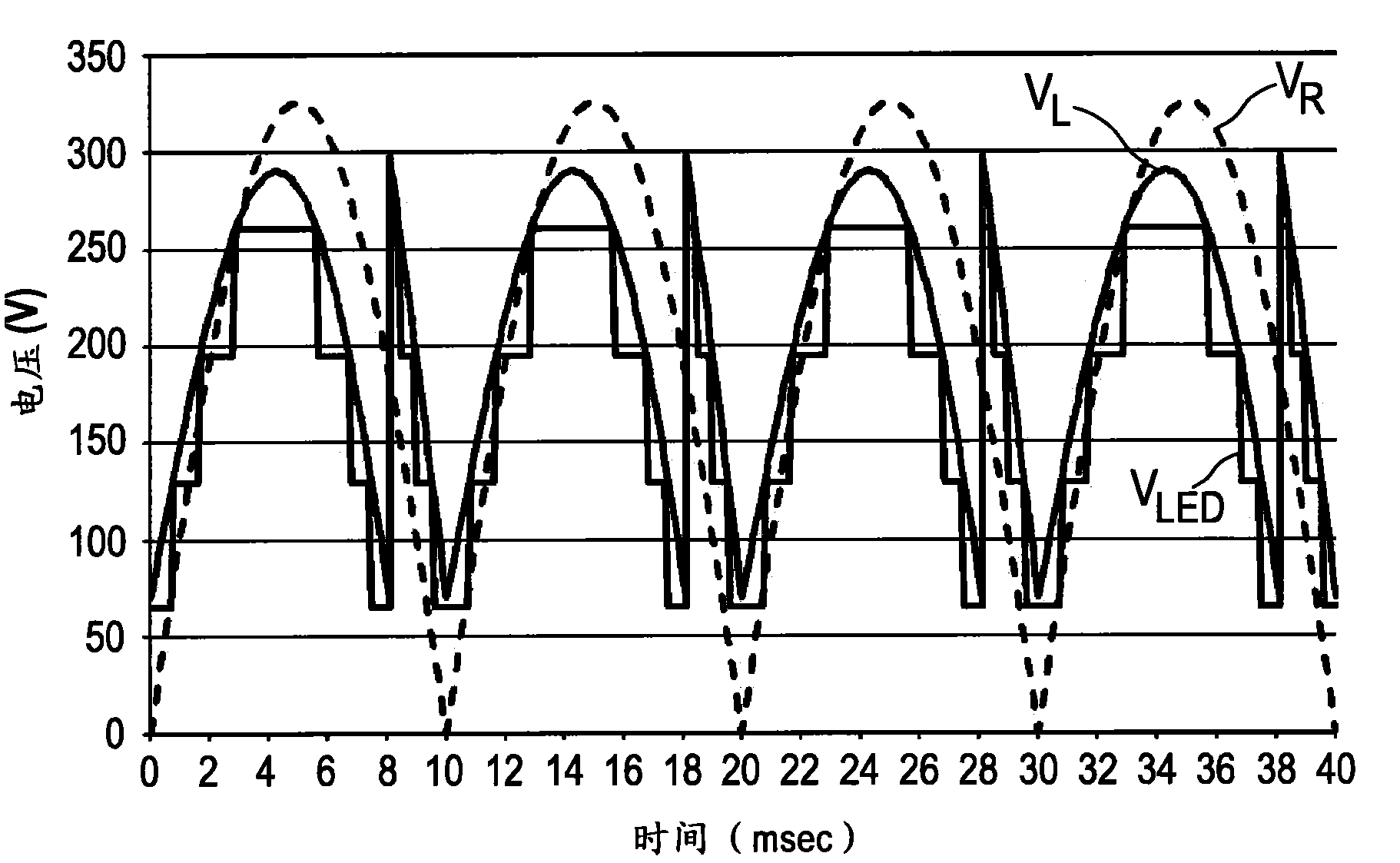

[0081] figure 1 A first embodiment of a driver device 10 (also called a driver circuit) according to the invention for driving a load 100, in particular an LED assembly comprising one or more LEDs, is shown. Said driver device 1 comprises means for passing the received AC mains voltage V S rectified to generate a rectified supply voltage V R The rectifier unit 10, the mains voltage supply provides the mains voltage V mains . The drive voltage V for driving the load 100 is provided at a pair of load terminals 20 L . The capacitive storage unit 30 is coupled between the rectifier unit 10 and the load 100 for storing the electric energy provided by the rectifier unit 10 and providing electric energy to the load 100 . A bridge switching unit 40 is coupled between the rectifier unit 10 and the load 100 for switching the capacitive storage unit 30 with the desired polarity into the load current path from the rectifier unit 10 to the load 100 and for switching the capacitive sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com