Inlet wire guide wheel assembly on trunk type take-up machine

A wire guide wheel and wire take-up technology is applied in the field of metal drawing equipment, which can solve the problems of uneven wire feeding, affecting wire take-up, and wire sliding out of the wire groove, so as to prevent the wire from sliding out of the wire groove. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings.

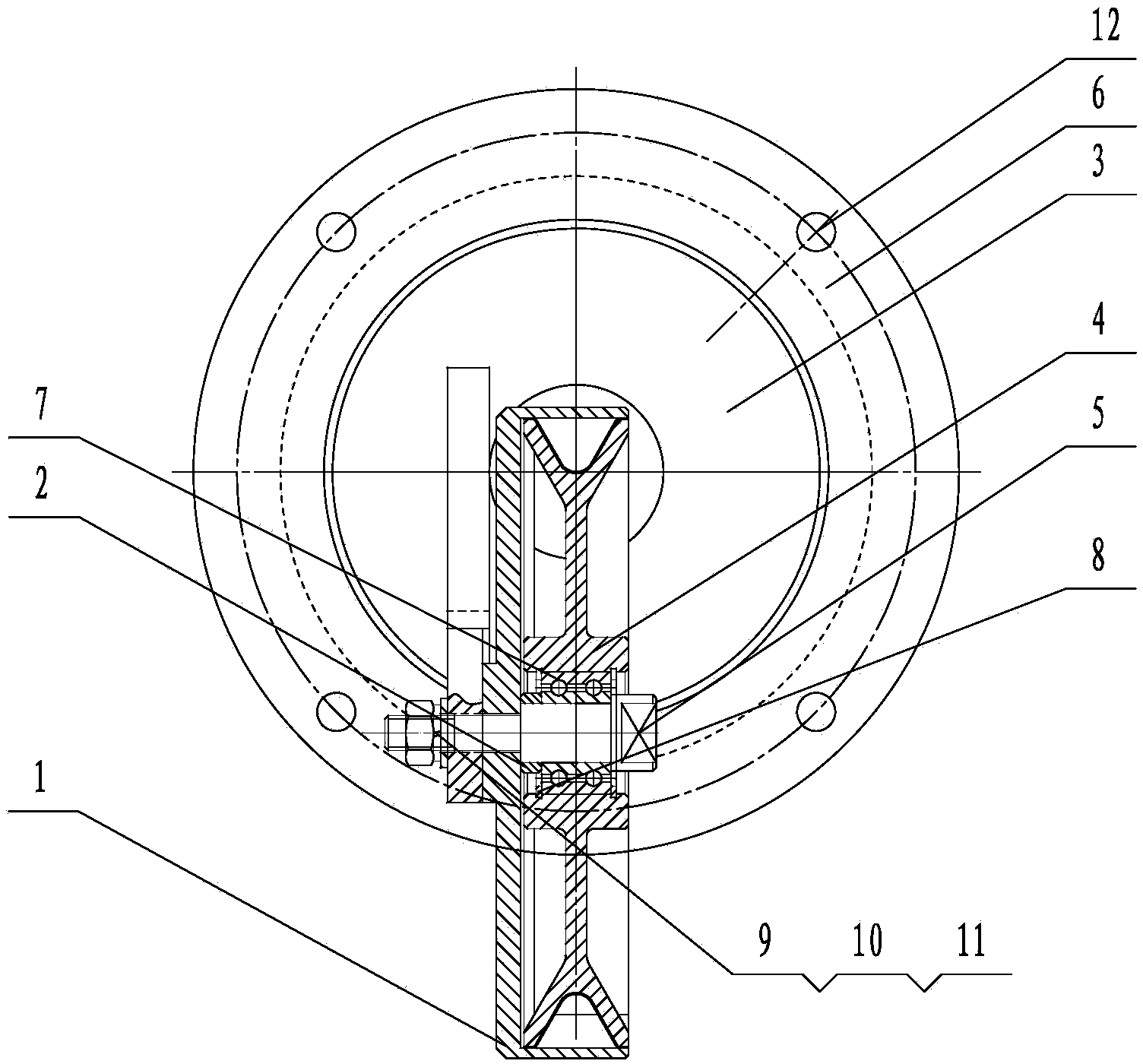

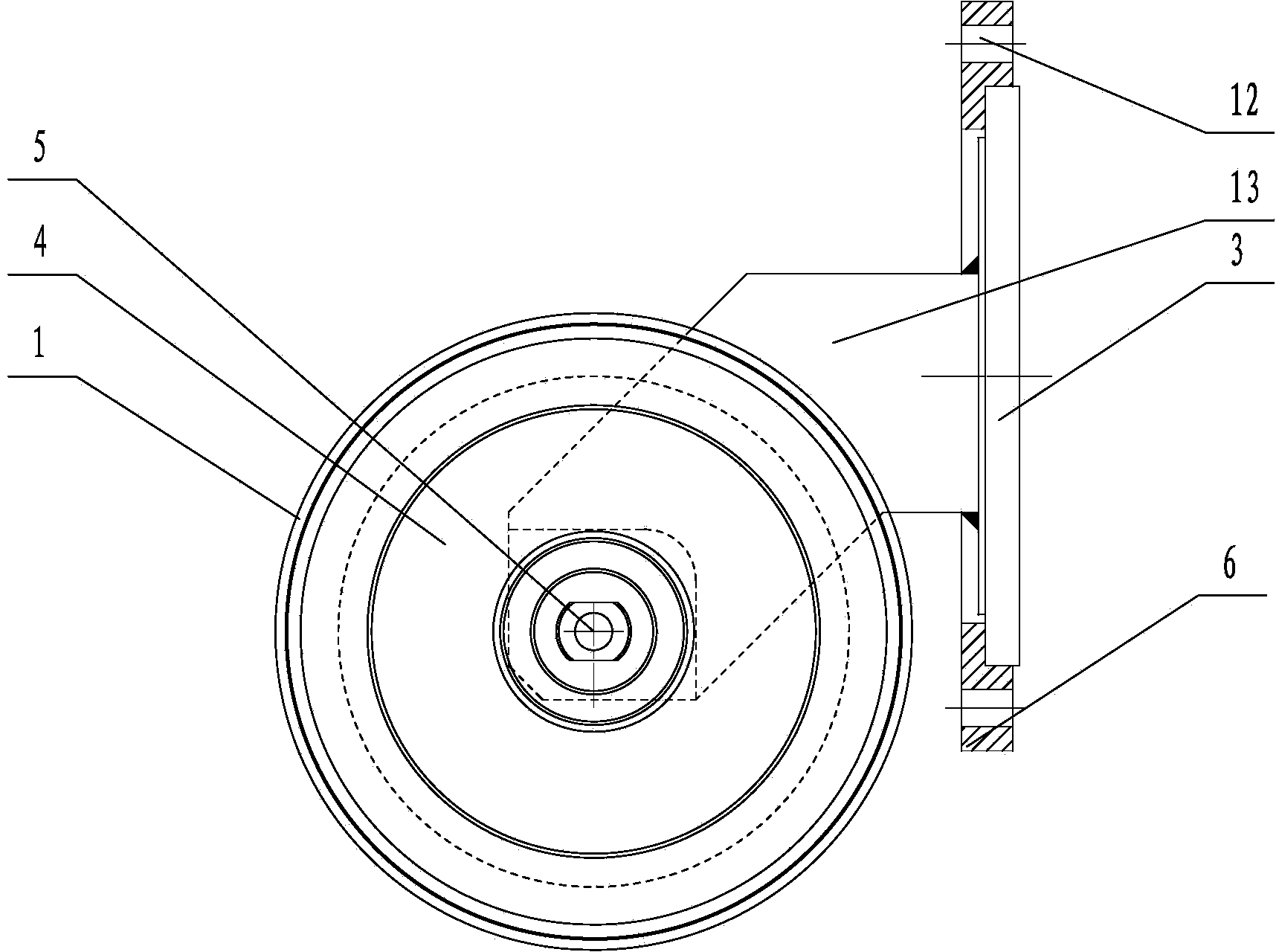

[0014] Such as Figure 1 ~ Figure 2 As shown: the incoming wire guide wheel assembly on the elephant trunk type wire take-up machine includes a retainer 1, a washer 2, a guide wheel seat 3, a guide wheel 4, a guide wheel shaft 5, a pressure plate 6, a deep groove ball bearing 7, and a Circlip 8, flat washer 9, spring washer 10, hex nut 11, fixing hole 12, bracket 13, etc.

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a guide wheel seat 3, the edge of the guide wheel seat 3 is provided with a pressure plate 6, and the pressure plate 6 is provided with a fixing hole 12, and the pressure plate 6 is used to fix the guide wheel seat 3 on the elephant trunk type wire take-up machine. On the guide wheel seat 3, a support 13 is set, and a guide wheel shaft 5 is installed on the support 13; one end of the guide wheel shaft 5 is fixed on the support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com