Three-jaw chuck for clamping synchronous belt pulleys

A technology of synchronous pulley and three-jaw chuck, which is applied in the direction of the chuck, can solve the problems of inconvenient grasp of the clamping force of the synchronous pulley and the influence of hole processing efficiency, etc., and achieve a simple structure, easy processing and manufacturing, and a large contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

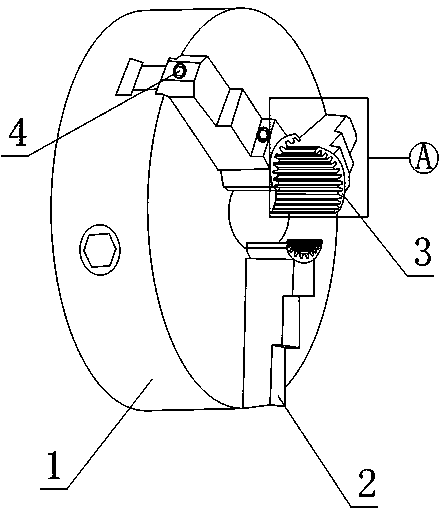

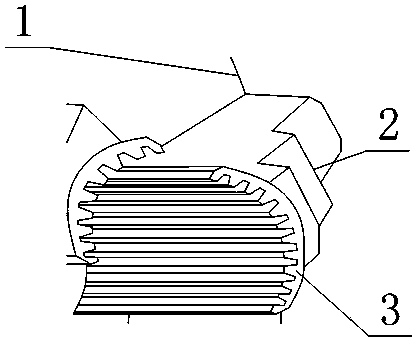

[0026] like figure 1 and figure 2 As shown, a three-jaw chuck for clamping a synchronous pulley includes a chuck body 1 and three jaws 2, the pressing surface of each of the jaws 2 is set as a circular arc surface, and also includes three Each arc-shaped pad 3 is fixedly connected to the pressing surface of a claw 2.

[0027] The pressing surface of the claw 2 in the form of an arc is fitted to the outer surface of the arc pad 3, and the inner surface of the arc pad 3 is fitted to the side of the synchronous pulley. The force between the pulleys, and the contact surface of the arc surface is conducive to increasing the contact area and reducing the force per unit area, so as to avoid damage to the side of the synchronous pulley when the clamping force is large.

Embodiment 2

[0029] This embodiment is further improved on the basis of embodiment 1, as figure 1 and figure 2 As shown, each of the arc pads 3 is provided with a plurality of rack-shaped grooves on the arc surface near the center of the chuck body 1, and each of the rack-shaped grooves is aligned with the direction of the chuck body. 1 parallel to the centerline.

[0030] A plurality of rack-shaped grooves are used to engage with the rack of the pulley when the present invention clamps the synchronous pulley, so that the force between the toothed rack of the synchronous pulley and the groove can prevent the synchronous pulley from moving relative to the claw 2 rotation, that is, the synchronous pulley can be fixed on the present invention without a large clamping force, which is beneficial to protect the synchronous pulley.

[0031] It also includes a plurality of connecting bolts 4, each of the claws 2 is provided with bolt holes, and each of the arc pads 3 is provided with internal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com