Welding device and control method thereof

A welding device and welding condition technology, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems that the arc striking effect cannot meet expectations, the design difficulty is increased, and the dynamic response performance is not high, so as to achieve excellent arc striking and Welding effect, the effect of shortening the control cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

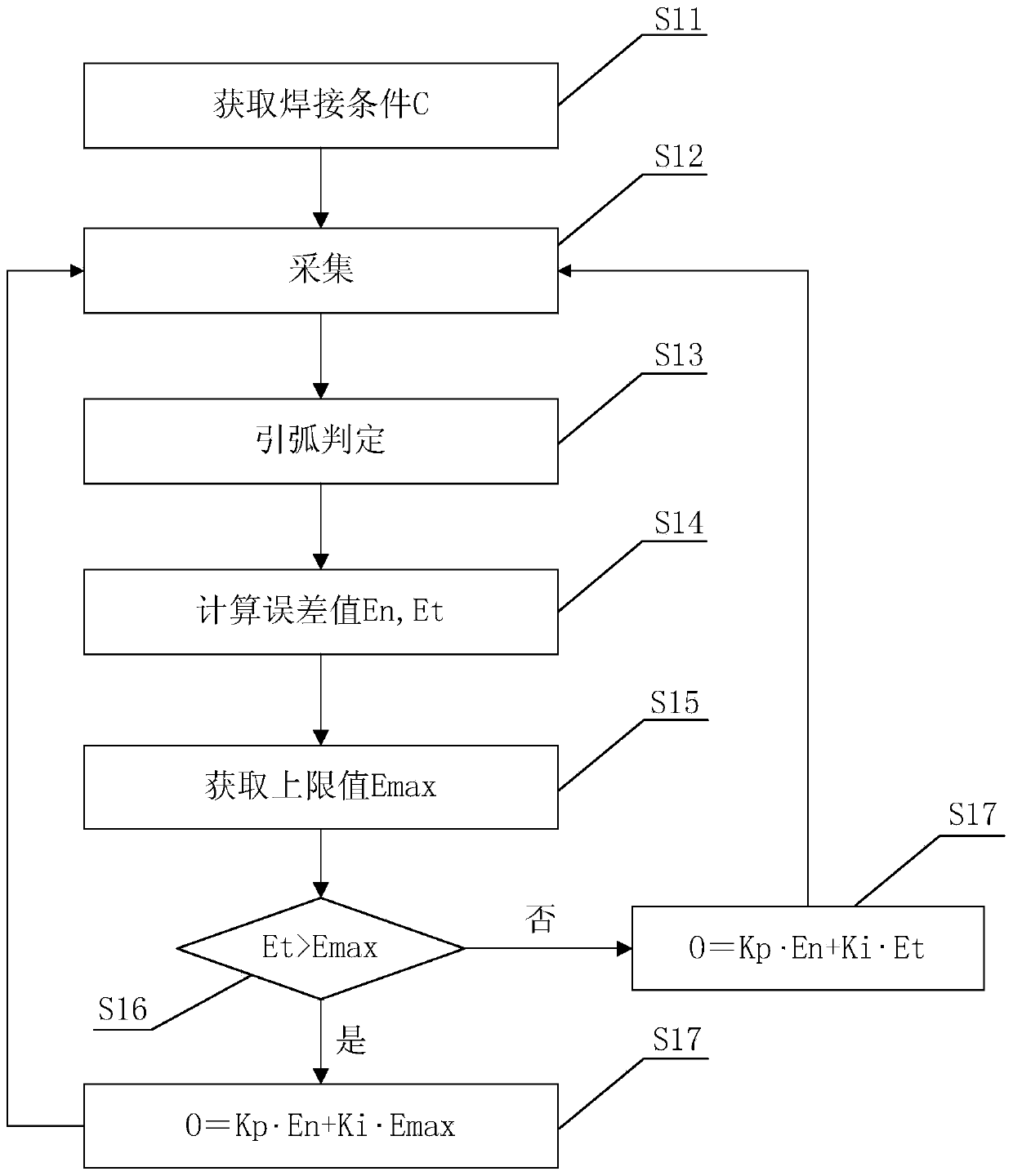

[0023] The core idea of the present invention is to pre-set the upper limit value Emax and the corresponding relationship R of the welding condition C and the arc striking stage f, then obtain the welding condition C, determine the arc striking stage f, and then according to the corresponding relationship R, welding condition C and In the arc ignition stage f, a reasonable and specific upper limit value Emax is obtained. Then, according to the reasonable upper limit Emax, a reasonable opening value O is obtained, so as to reasonably control the output energy of the welding machine.

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] [welding device]

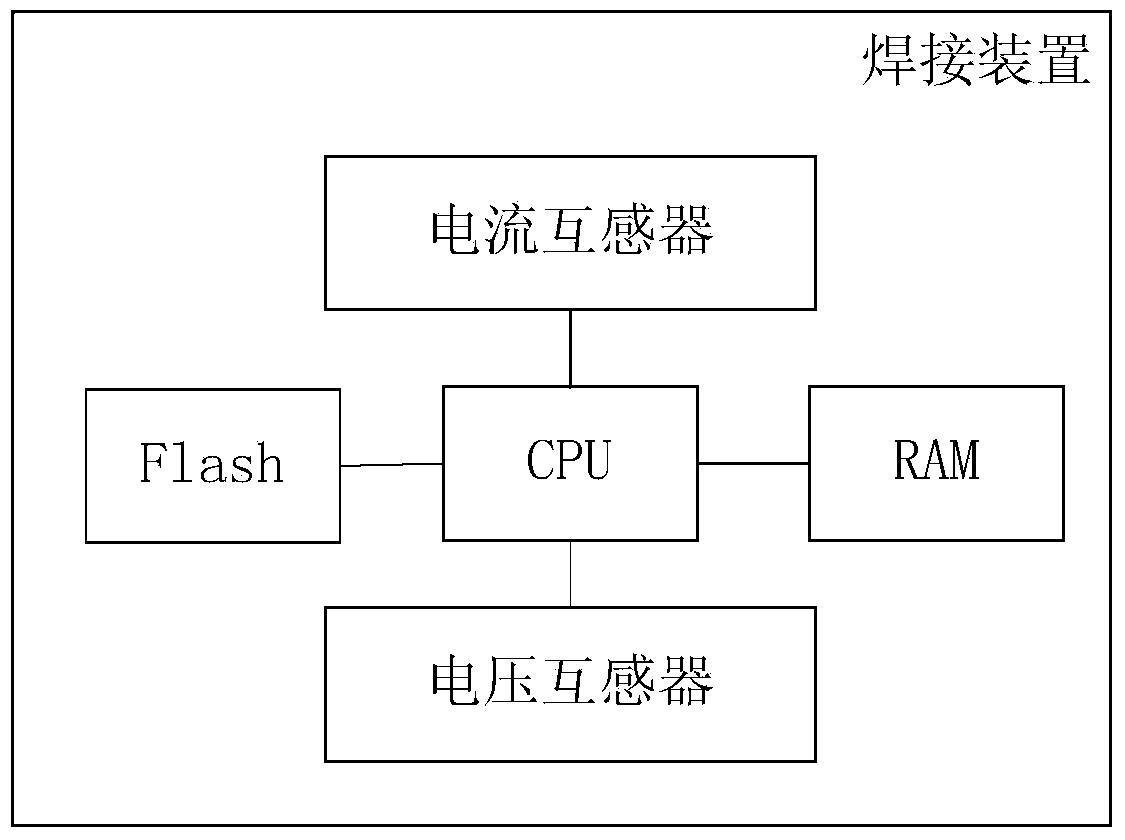

[0026] Refer below figure 1 with figure 2 The welding device of the present invention is described.

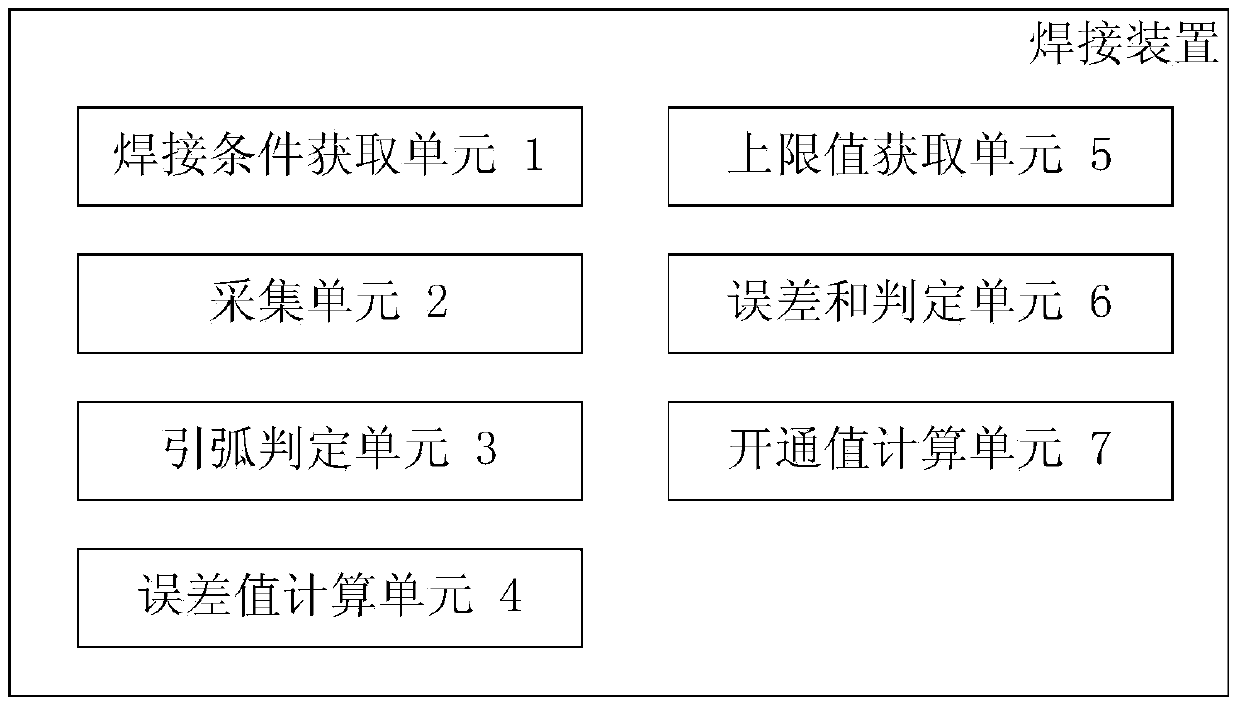

[0027] Such as figure 1 As shown, the welding device of the present invention includes: a welding condition acquisition unit 1, an acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com