Sofa surface layer automatic forming equipment

An automatic forming and surface layer technology, applied in the direction of presses, presses, manufacturing tools, etc. using rotating pressure components, can solve the problems of high labor intensity of workers, difficult to guarantee product quality, and human factors, and shorten working time. , Easy to operate, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

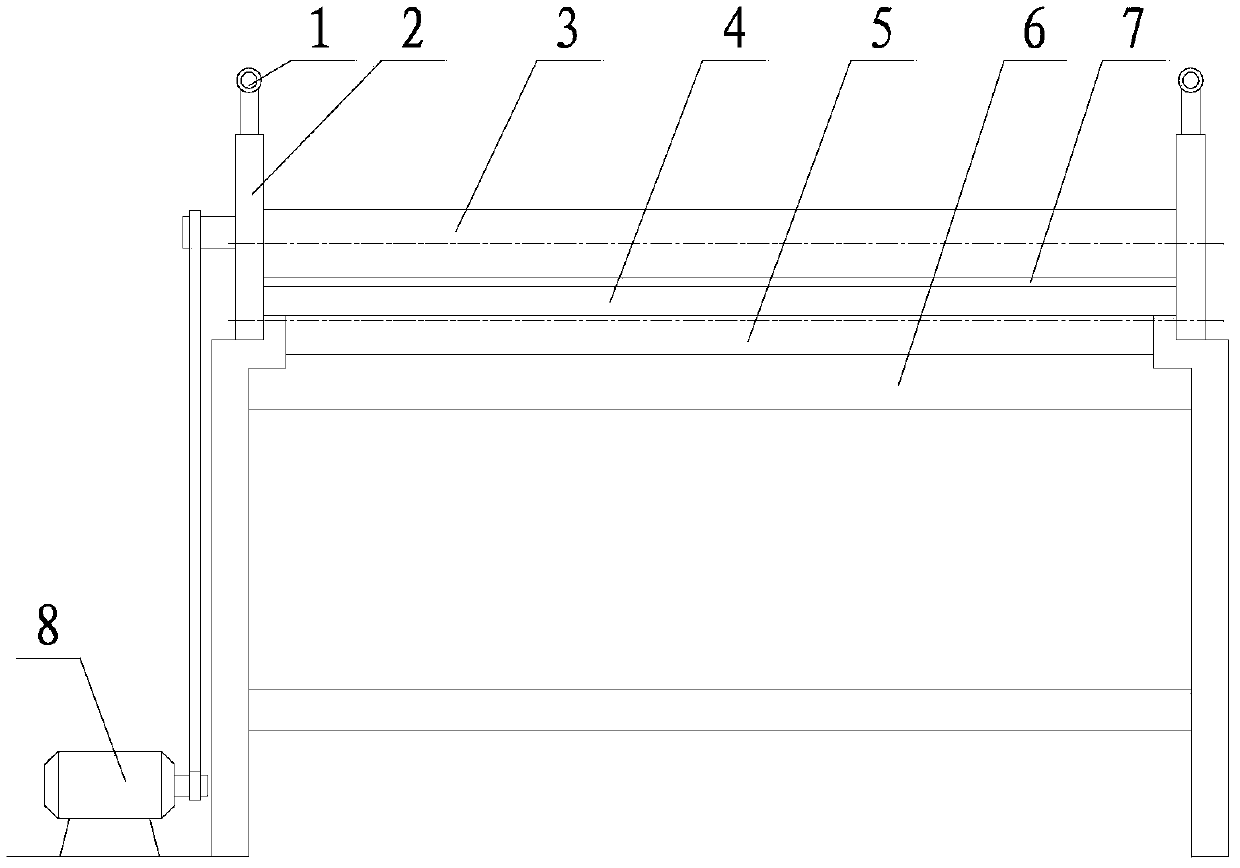

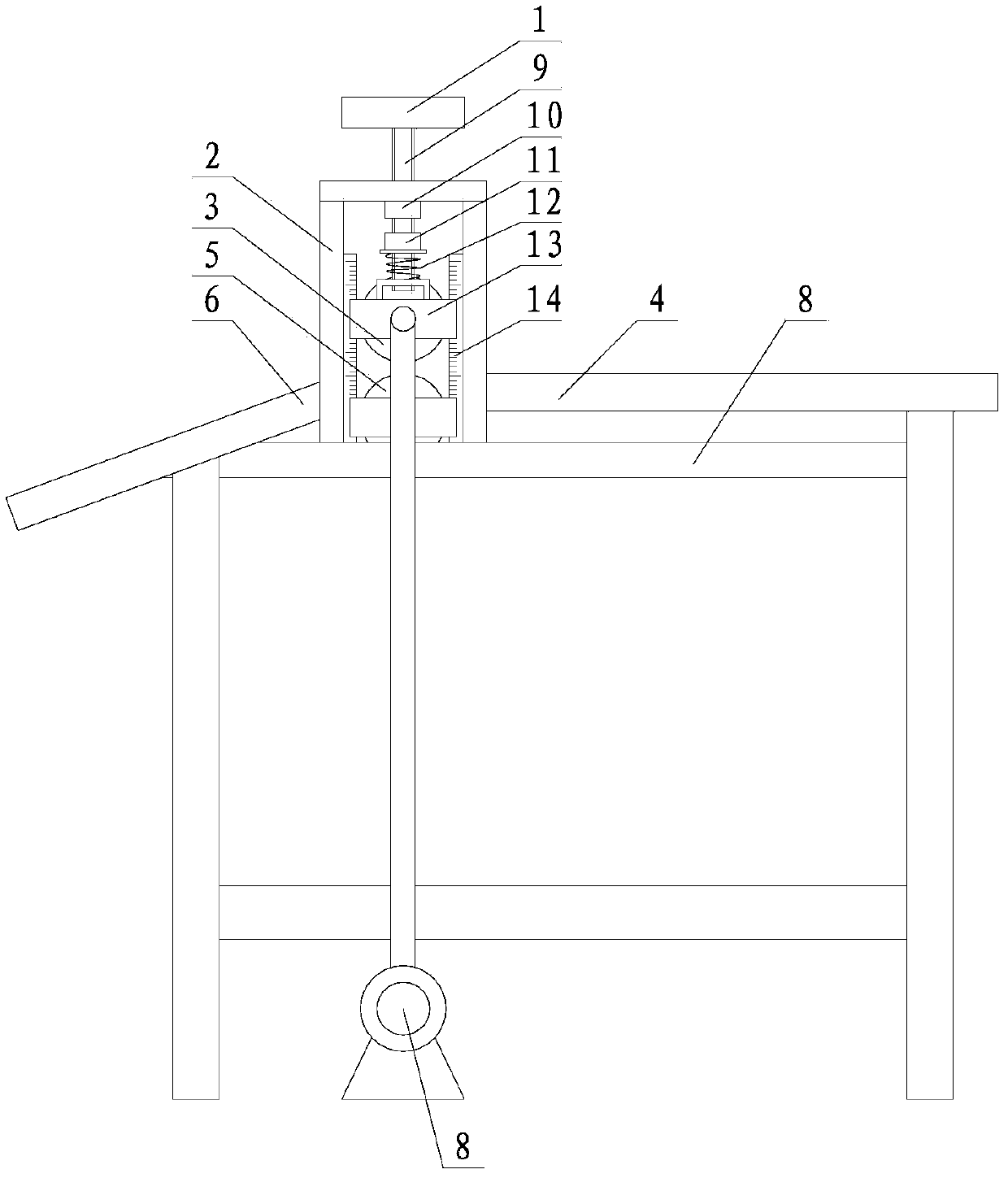

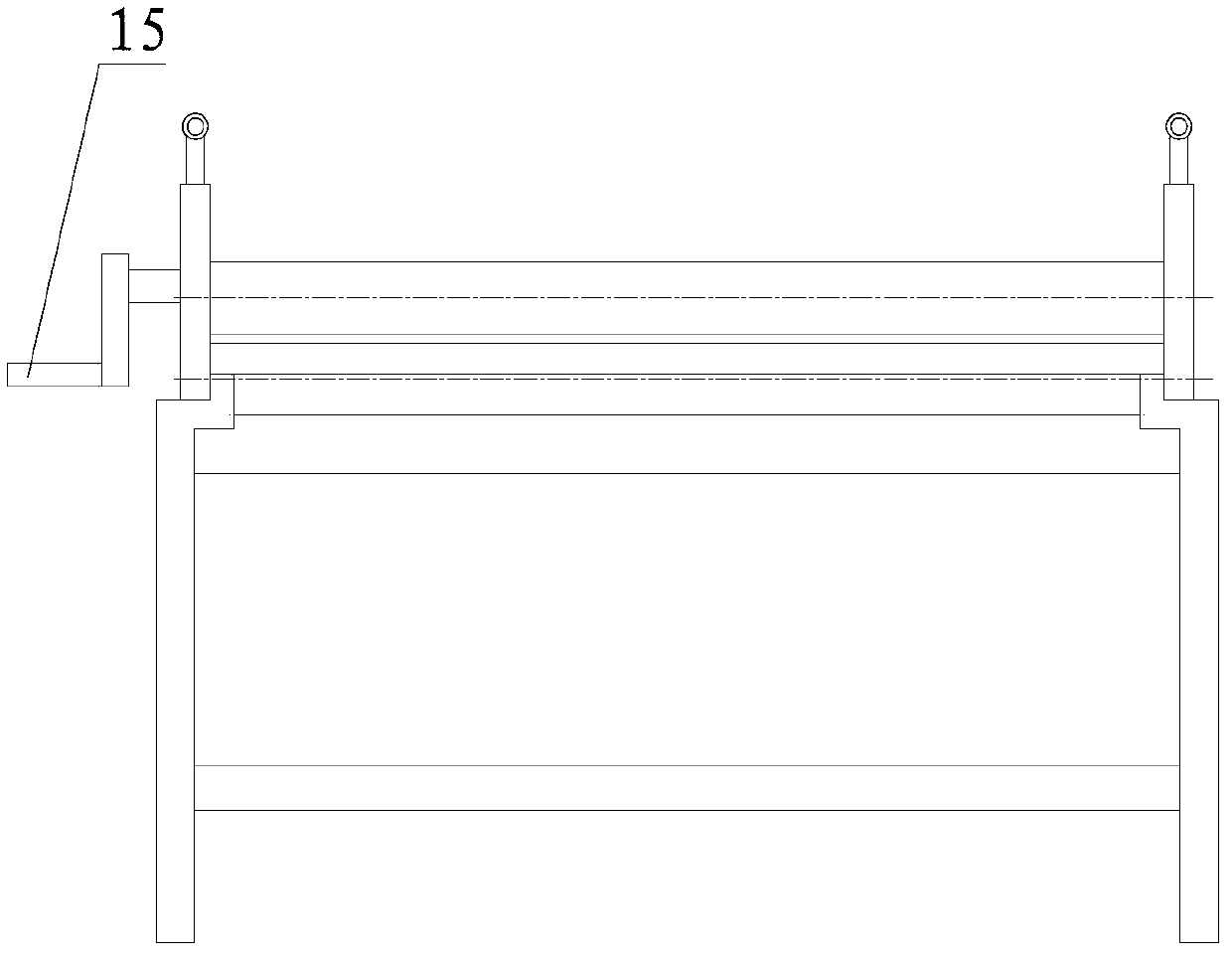

[0021] An automatic sofa surface forming equipment includes a horizontal workbench 4, and an oblique discharge table 6 arranged obliquely downward is installed at the rear end of the horizontal workbench, and the oblique discharge table is located behind the driving roller and the driven roller. A supporting frame 2 is installed at the left and right ends of the horizontal workbench, and a driving roller 3 and a driven roller 5 are installed between the two supporting frames. The driving roller and the driven roller are arranged side by side up and down. There is a gap 7 for raw materials to pass through, and the gap can be adjusted. Its specific structure is: vertical guide rails 14 are made on the inner sidewal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com