Production process of low compression ratio thick container plate

A production process and bit reduction technology, which is applied in the field of low compression bit thick container plate production process, can solve the problems of low production efficiency, environmental pollution, and low yield, and achieve high-temperature tensile properties, good economy, and surplus strength Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

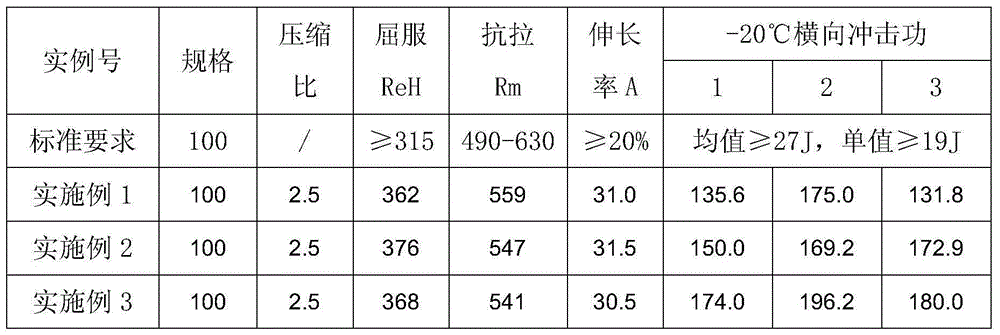

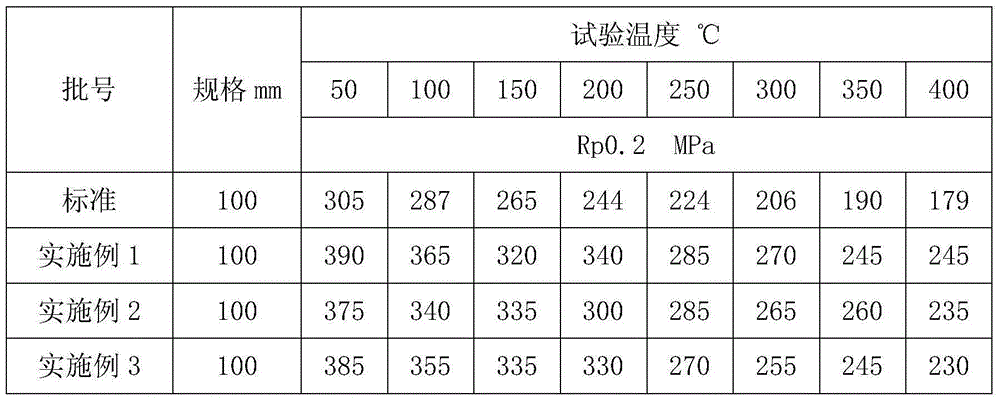

Examples

Embodiment 1

[0032] The grade of the low compression ratio thick container steel plate in this example is European standard P355GH, which is prepared from the following components by mass percentage: C: 0.20%, Si: 0.36%, Mn: 1.61%, P: 0.014%, S: 0.003%, Nb: 0.030%, Ti: 0.016%, Alt: 0.027%, O: 0.0019%, N: 0.0028%, H: 0.00017%, and the balance is Fe and unavoidable impurities.

[0033] The production preparation method of the low compression ratio thick container steel plate P355GH of the present embodiment is as follows:

[0034] The specific embodiment is to adopt 250mm continuous casting slab to roll 100mm P355GH extra-thick steel plate for pressure vessel, including steps: smelting, LF refining, RH refining, continuous casting, slow cooling, heating, rolling, slow cooling, normalizing.

[0035] 1) Smelting: The raw materials are desulfurized by molten iron KR pretreatment to reduce the mass fraction of sulfur to less than 0.003%. After smelting in a 210t top-bottom combined blowing conve...

Embodiment 2

[0041] The grade of the low compression ratio thick container steel plate in this example is European standard P355GH, which is prepared from the following components in mass percentage: C: 0.20%, Si: 0.35%, Mn: 1.58%, P: 0.012%, S: 0.001%, Nb: 0.032%, Ti: 0.018%, Alt: 0.035%, O: 0.0017%, N: 0.0025%, H: 0.00015%, and the balance is Fe and unavoidable impurities.

[0042]The production and preparation method of the low-compression ratio thick container steel plate P355GH of this embodiment is the same as that of the first embodiment, the difference is that the refining temperature of the LF refining furnace is controlled to 1620 ° C, and the molten steel is softly blown with argon and weakly stirred for 15 minutes after the RH vacuum treatment is completed and the line is fed. After the continuous casting slab is off-line, it enters the slow cooling pit for 72 hours, and the pit temperature is 178°C. The casting slab is heated in the furnace for 4.0 hours, and the heating temper...

Embodiment 3

[0044] The grade of the low compression ratio thick container steel plate in this example is European standard P355GH, which is prepared from the following components in mass percentage: C: 0.18%, Si: 0.36%, Mn: 1.57%, P: 0.012%, S: 0.001%, Nb: 0.030%, Ti: 0.017%, Alt: 0.037%, O: 0.0017%, N: 0.0029%, H: 0.00016%, and the balance is Fe and unavoidable impurities.

[0045] The production and preparation method of the low-compression ratio thick container steel plate P355GH in this example is the same as in Example 1, the difference is that the refining temperature of the LF refining furnace is controlled to 1618°C, and the molten steel is softly blown with argon and weakly stirred for 20 minutes after the RH vacuum treatment is completed and the line is fed. , After the continuous casting slab is off the assembly line, it enters the slow cooling pit for 72 hours, and the pit temperature is 188°C. Cool to 185°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com