Water leakage preventing system of exposed framing glass curtain wall

A glass curtain wall, anti-leakage technology, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems such as affecting the overall performance and service life of the glass curtain wall, unsolved, water leakage, etc., to achieve novel and ingenious design and solve water leakage , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

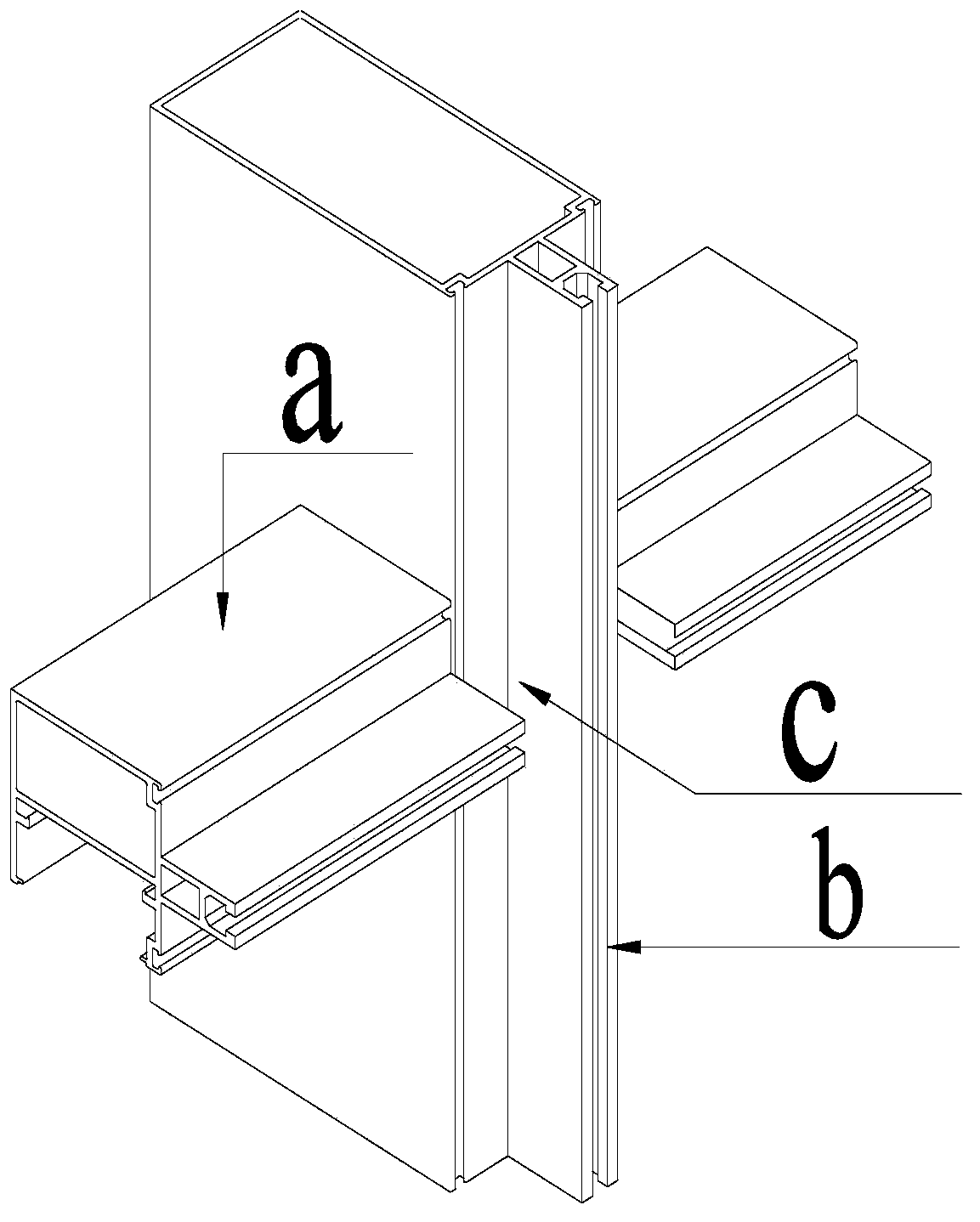

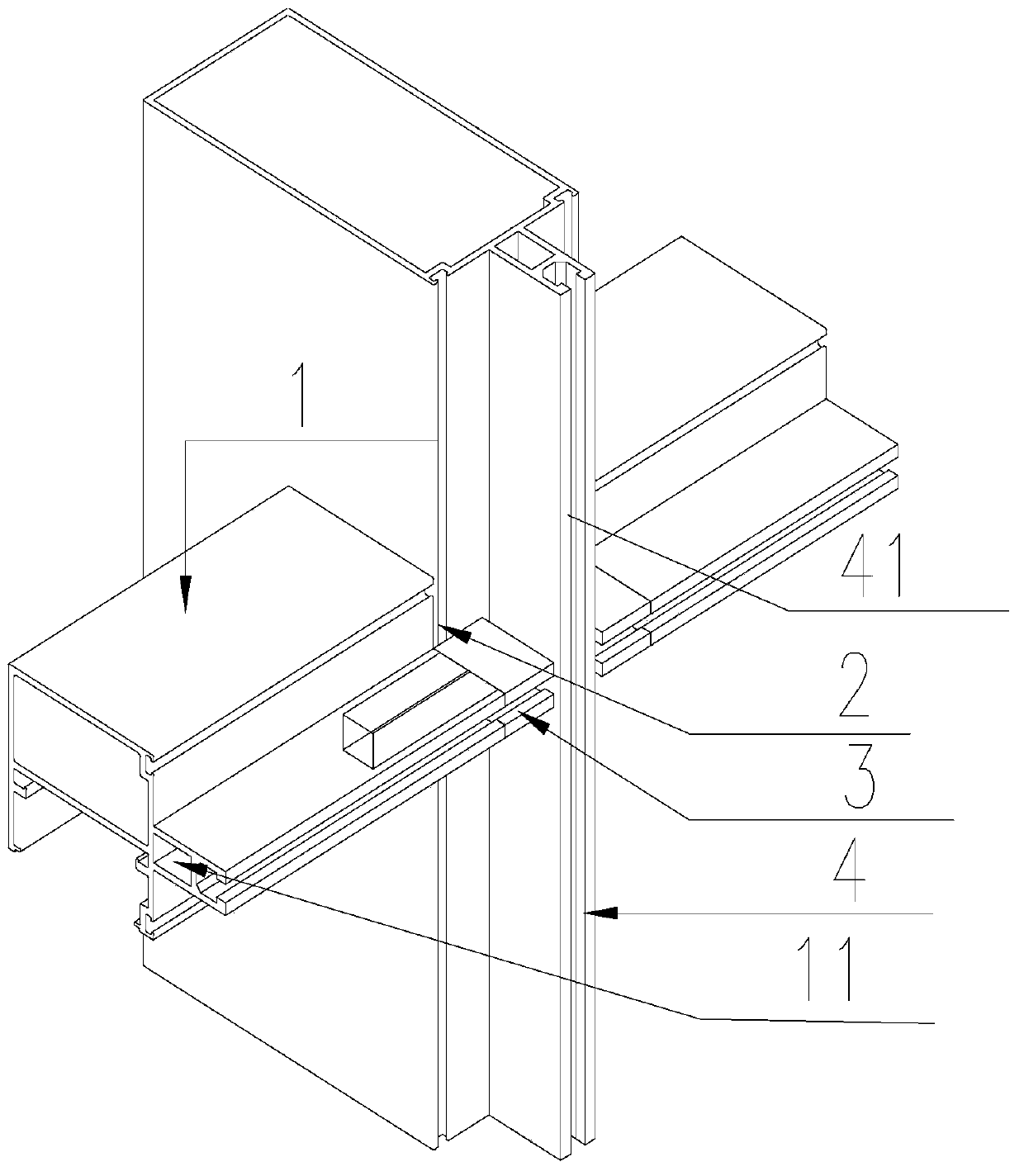

[0013] Such as figure 1 As shown, an exposed frame glass curtain wall water leakage prevention system, the exposed frame glass curtain wall includes a beam 1 and a column 4, the beam 1 and the column 4 are arranged at 90 degrees, the outer channel plate 41 of the column and the beam There is a gap between the outer channel plates 11, and the anti-leakage system includes a leak-proof plug-in 3, one end of which is inserted into the cavity of the outer channel plate 11 of the beam, and the other end passes through the gap and connects with the outer channel plate 41 of the column. The fixed connection seals the gap between the outer channel plate 41 of the column and the outer channel plate 11 of the beam.

[0014] A sealant 2 is provided at the joints of the leak-proof plug-in 3 with the beam 1 and the column 4 respectively. The anti-leakage plug-in 3 includes a plug and a blocking block, the plug is inserted into the cavity of the outer channel plate 11 of the beam, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com