Boom manufacturing method, boom manufactured by using method and pump truck using boom

A manufacturing method and a boom technology, which are applied to the boom manufactured by the method, the boom manufacturing method, and the field of the pump truck boom, can solve the problems of affecting the strength of the boom, no process method, and load reduction, etc., and can save energy. De-soldering time, small processing volume, and the effect of reducing processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical content claimed in the present invention will be described briefly and clearly below in conjunction with specific embodiments. Obviously, the examples listed are only a part of all implementations, and are intended to illustrate the technical content of the technical solution. Anyone skilled in the art can clearly make other implementations according to this application document and still belong to the protection scope of this application document. .

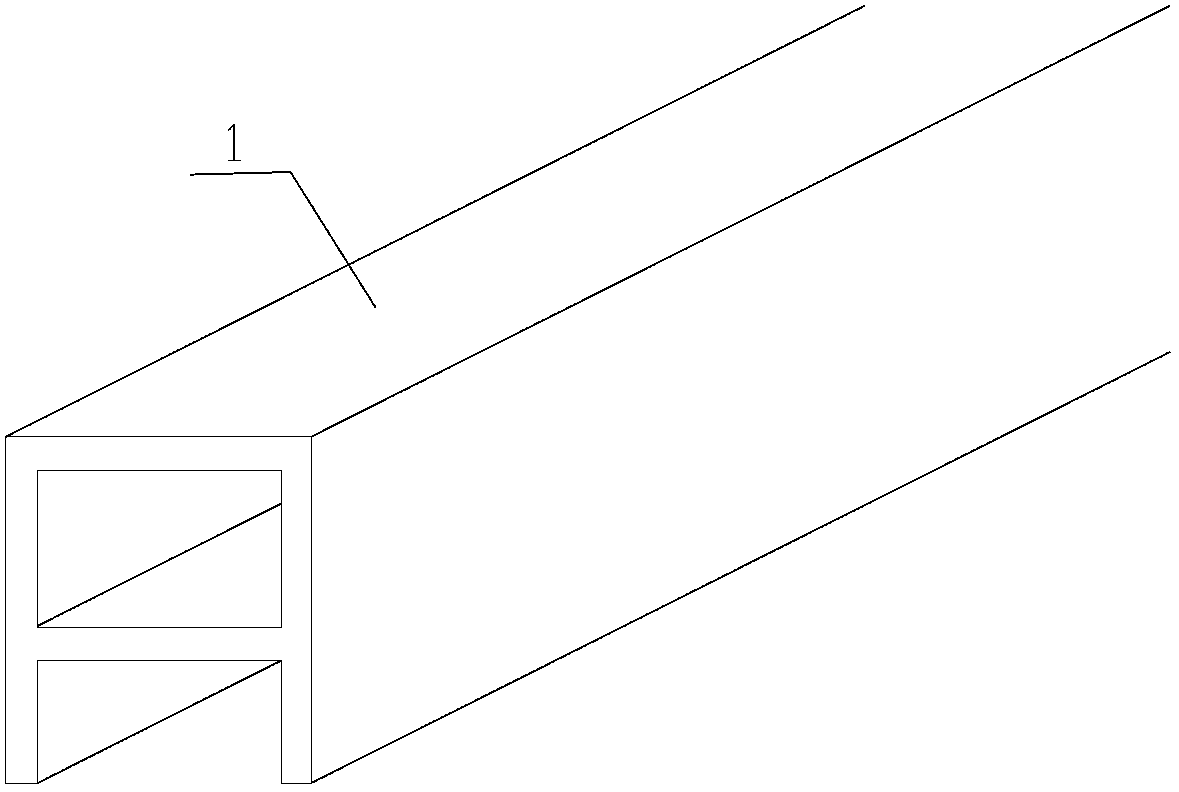

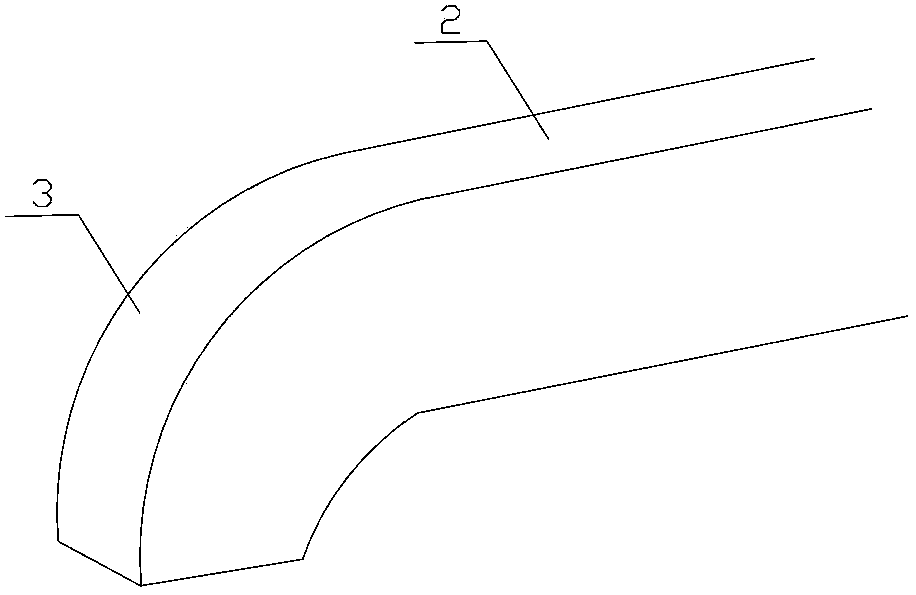

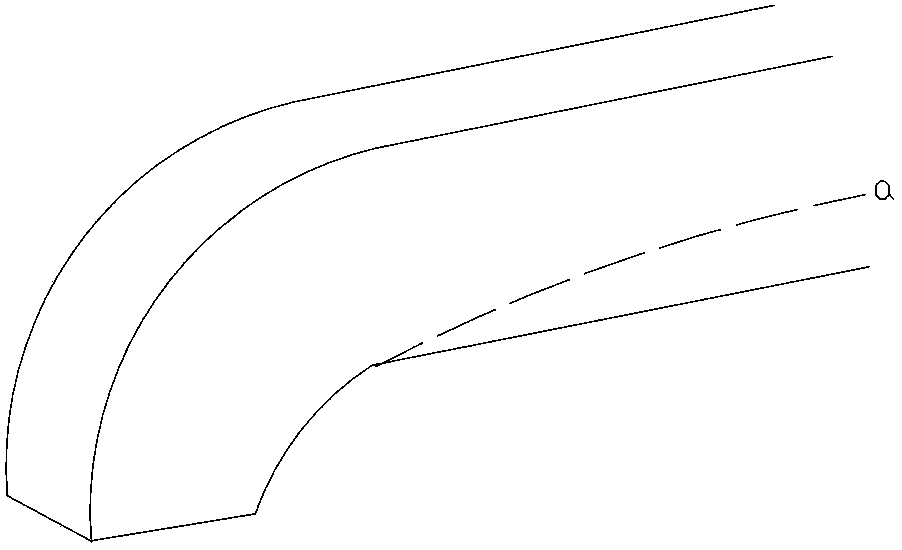

[0032] refer to figure 1 , 2 , a method of manufacturing a boom, comprising the following steps:

[0033] A. Extrude the aluminum alloy profile 1;

[0034] B. Bending at least one end of the aluminum alloy profile to form a main body 2 and a head 3 at a predetermined angle;

[0035] Optionally, the aluminum alloy profile is subjected to quenching treatment, and the quenching treatment is before the bending treatment;

[0036] Optionally, aging treatment is performed on the bent aluminum alloy profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com