Bionic piezoelectric foot type driver

A driver, bionic technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of low transmission efficiency, small stroke, complex structure, etc. The effect of large stroke, simple structure and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

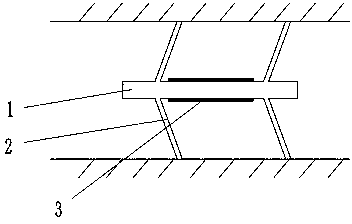

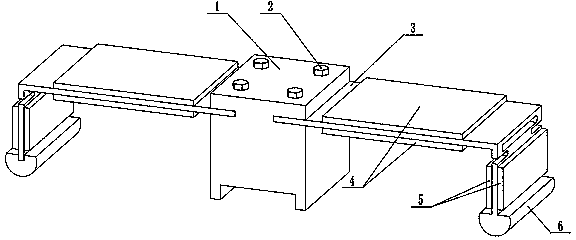

[0016] Such as image 3 and Figure 4 As shown, two driving feet of the driver are arranged symmetrically at both ends of the driver main body 1, and the driving feet of the driver are composed of a metal substrate 3, two piezoelectric ceramic wafers one 4, two piezoelectric ceramic wafers two 5 and a cylindrical The friction block 6 is composed of a metal substrate 3 composed of a beam and a vertical beam. One end of the beam of the metal substrate 3 is fixed on the driver main body 1 through a screw 2. Two piezoelectric ceramic wafers 4 are symmetrically glued on the upper and lower sides of the beam of the metal substrate 3. Two piezoelectric ceramic chips 25 are symmetrically bonded to the left and right sides of the vertical beam of the metal substrate 3, and a cylindrical friction block 6 is affixed to one end of the vertical beam of the metal substrate 3.

[0017] Way of working:

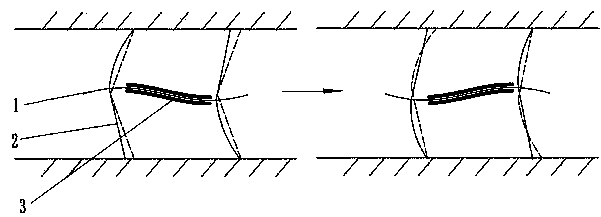

[0018] When the driver works, the period of the driving electric field signal acting on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com