Low-damage threshing method for corn ear

A corn ear, low-damage technology, applied in the field of corn kernel threshing theory research, can solve the problems of laboriousness, damaged kernels, large energy consumption, etc., and achieve the effects of reducing energy consumption, correct analysis, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

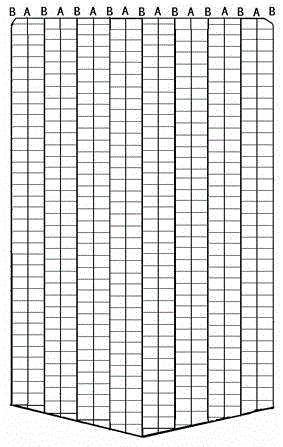

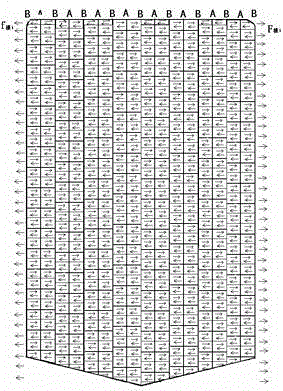

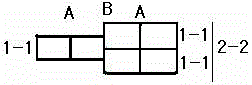

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0028] A method for threshing corn ears with low damage, comprising the following steps:

[0029] Step 1, peel off the corn husks from the ears of corn to be threshed, remove the corn silk, and set aside;

[0030] Step 2. Establish the balance model of corn ear circulation force:

[0031] 1) Define the resultant force of corn cob grains in the horizontal, vertical and radial directions as the circular force, the lateral force is the force along the circumferential direction, the longitudinal force is the force parallel to the direction of the cob axis, and the radial force is the force along the direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com